Kansas-based Hamm Companies Saves Surveying and Data Processing Time with Propeller

Founded in 1954, Hamm Companies is a leader in the Midwest in highway construction, aggregates, and waste services. Based in Perry, Kansas, they have projects ranging from asphalt plants, hospitals, wastewater plants, to road corridors, and a lot of quantities to track between sites.

Hamm came early into the drone surveying scene after buying their first drone in 2013, and they’ve been flying since.

In the beginning, they processed all their own data in-house. “I was proud of doing my own data,” said Paul Johnson, a survey and construction technology manager at Hamm who handled the drone program and brought Propeller onboard. “But it just got to be so much. Processing projects was like boiling water—you gotta [stay there to] watch it.”

Hamm is using Trimble Stratus, powered by Propeller. Trimble, the global leader in positioning technologies, was an early partner of Propeller. Our teams work closely together to deliver Trimble Stratus survey-grade drone data solutions for the heavy civil industries

Processing data with Propeller means Hamm can do more and fly more

As Hamm grew, so did their data needs. “We needed data more frequently and it got to be overwhelming to process ourselves,” remembered Johnson. “It was a no-brainer to switch once we figured out how smooth Propeller was for processing and sharing the drone data.”

Outsourcing has relieved the burden of in-house processing and opened the door for Hamm to scale use further. Today, they fly most quarries quarterly or monthly, and expect that frequency to ramp up.

Colton Aholt, a mining engineer by training, has recently come onboard to help with the expanding drone program. When asked what it was like to get up-to-speed on all things drone surveying and Propeller, he said, “I’ve used AutoCAD before. Propeller was way easier to use than any other computer program I’ve ever used. In a couple of days, I was pretty confident in the program.”

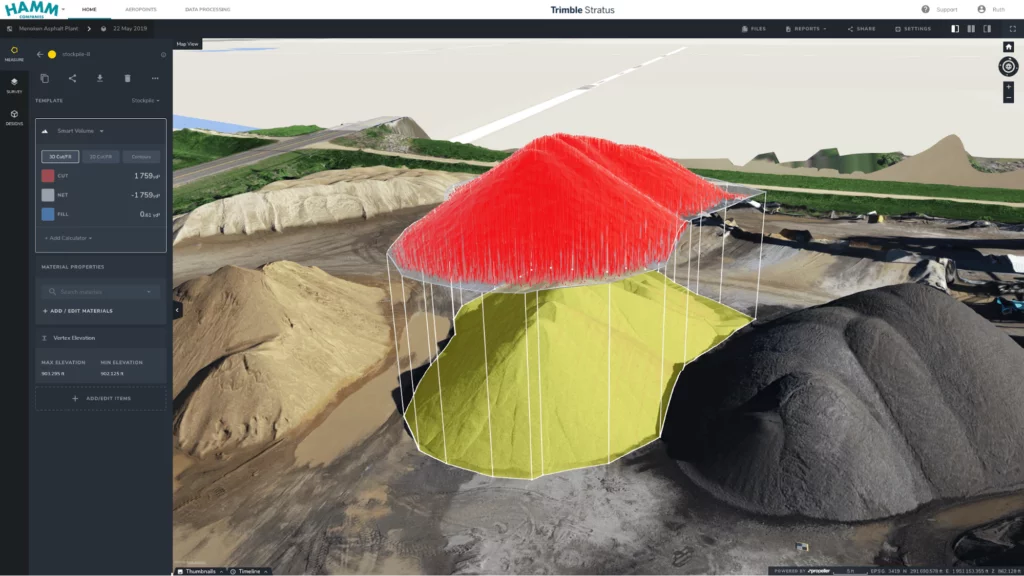

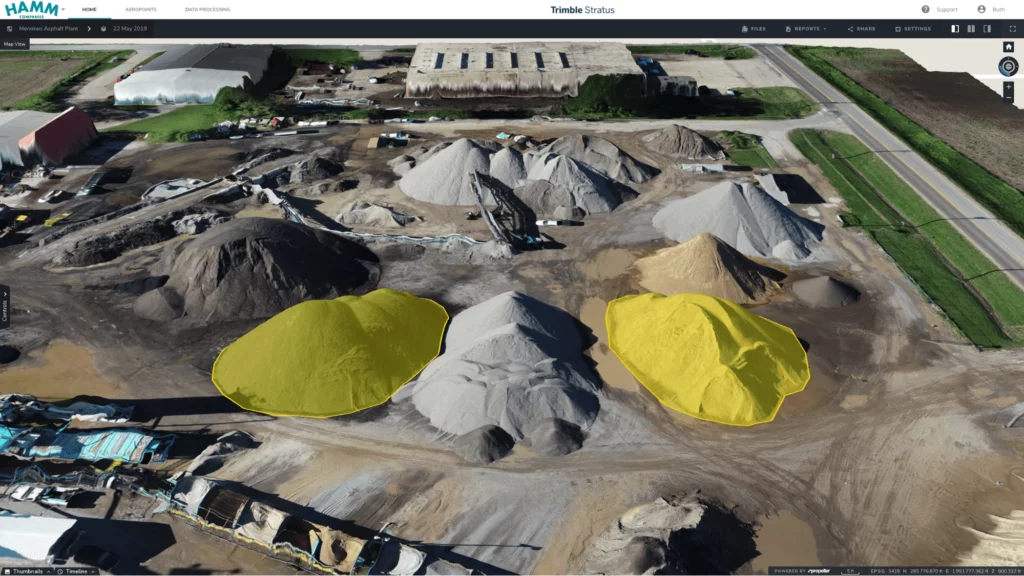

Hamm uses drones, Propeller for inventory management and safety

Hamm first investigated drones to manage their many quarry stockpiles. “Walking piles was just too time-consuming for the data we were going to get. I knew that the only way to get a good number was to do it from the air with the sheer size of the piles we got,” said Johnson.

But using drones to survey their stockpiles further helps Hamm improve worker safety. “Another big reason we went with a drone was the safety factor,” explained Johnson. Sending the drone up means he and his team can stay on solid ground, drastically reducing the inherent safety risks in surveying stockpiles on foot.

“It’s a much safer alternative to walking up and down steep, tall, or jagged piles,” Johnson said. “Not having to physically scale them was a huge win.”

Hamm’s initial decision to use drones for surveying has led to expanding the practice on more than a dozen quarries and multiple construction sites. “We just got another two projects we’re trying to fly. One was a $300M job in Kansas City for a wastewater plant. It’s a new construction—demoing the old site and putting in a new one in,” said Johnson.

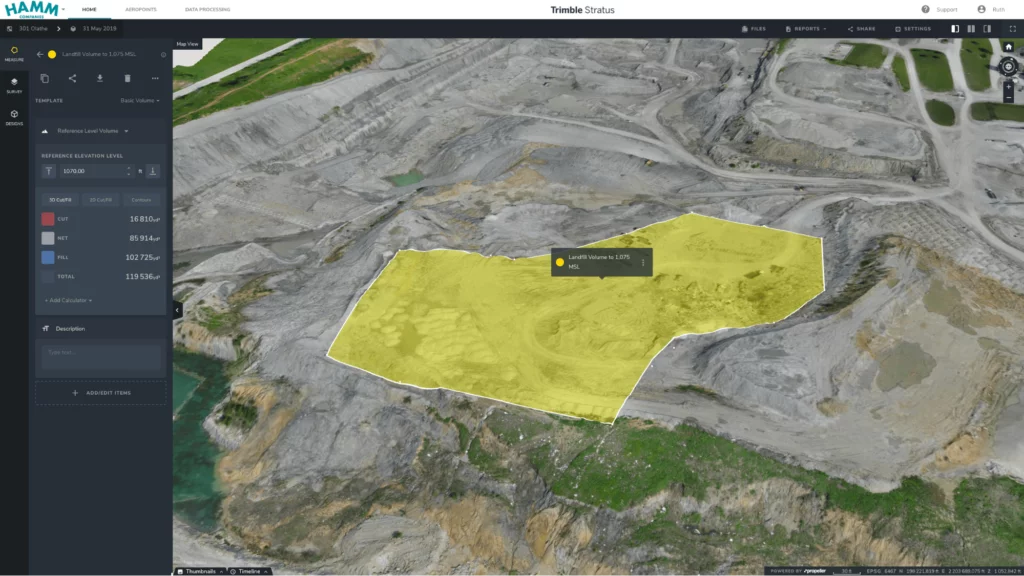

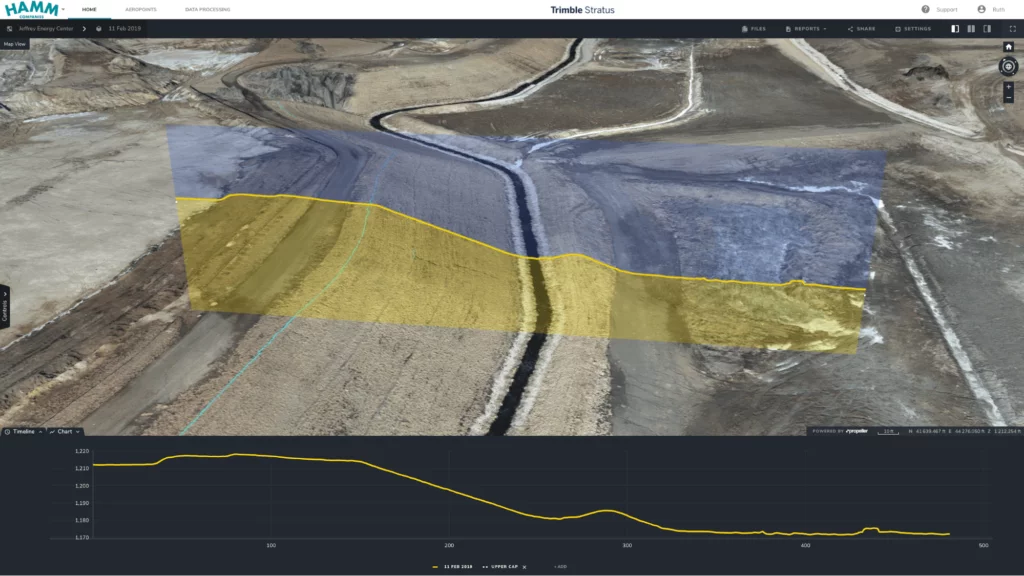

Use case: flying landfills for as-builts

One of the most interesting ways Hamm is using drone surveying and Propeller is on their landfill sites is for as-builts.

On one site, they flew consistently before, after, and during building. “We had to prove our cap was [the right thickness]. We’d fly it before, we’d fly it after, just planning how much dirt was going to take. I normally supply the data to whoever needs it,” noted Johnson.

Having all that recorded site data meant they could use it for more than progress reporting. “We ended up using it as as-built information,” said Johnson.

3D site models improved data sharing, collaboration

Beyond freeing up resources from data crunching, Propeller opened up new avenues for sharing survey information and collaboration. “Before it was just landlocked on my computer. There was no sharing measurements or bouncing ideas off each other,” noted Johnson.

Today, Johnson and Aholt do most of the measurements in the Platform while bringing on their plant managers to do measurements themselves. “Many aren’t familiar with their technology, which is fine because of how easy and straightforward Propeller is to use,” said Aholt. They also grant access to subcontractors to monitor project quality.

Getting people onboard takes a little as letting them click around Propeller on their own. “They realize they can [get measurements] themselves instead of calling. I’ve already shown a couple guys how to use it and haven’t heard back from them since. Not even for little questions like, ‘how do I find the area?’ or ‘how do I measure the distance from the pump to the hillside?’” Aholt explained further.

Going forward, Hamm will use Propeller as the company standard

In addition to expanding drone surveying for its projects, Hamm is also making Propeller a company standard for data visualization and processing.

“We’re going to try to get to a point where everyone is attuned to this and it’s a part of our business,” said Johnson. “Everyone’s was a little afraid of Propeller at first. But the information it has is too valuable for you to just fly and only have a couple people look at.”

Hamm Companies uses Trimble Stratus powered by Propeller. For more information on how to bring Trimble Stratus to your site to help create machine surfaces and process data faster, please contact your local SITECH dealer.

Download this case study in PDF here.