Volume and Productivity Tracking made easy

Gain visibility into production activities with survey-grade machine sensors and volume measurements, available daily.

Get startedConstruction and earthworks teams across the world are using drone technology paired with Propeller PPK to collect, process, analyze, and visualize this data for productivity tracking and to improve their business. While drone surveys capture data from the sky, DirtMate captures data on the ground. Working together, drone surveying and DirtMate puts your production data front and centre for your team.

Mounted on the cab of machines on site and equipped with GPS, DirtMate continuously provides machine location and elevation. DirtMate surveys and captures the ground beneath tyres or tracks to automatically generate key production data every day, on demand.

Gain access to rich, accurate worksite data and production efficiency insights that are simple to view, understand, share, and use.

Fill the gaps in your site data and

gain a competitive edge

Critical productivity data is often gathered infrequently and pulled from many (often disconnected) sources, leading to gaps in the data that impair your ability to effectively manage your project day-to-day.

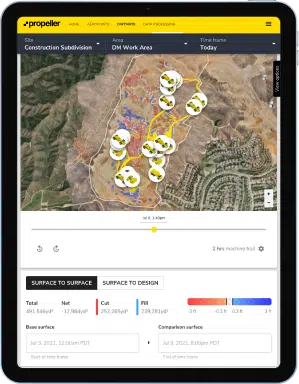

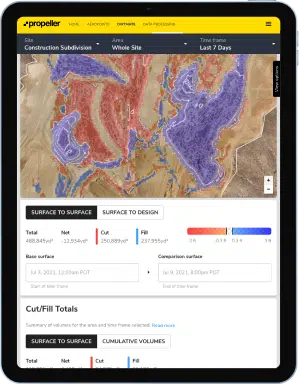

DirtMate helps fill in those gaps, giving you a complete and highly accurate view into your operations. With DirtMate and your high-accuracy survey data, you’ll have a holistic, up-to-date view of your site, complete with daily volumes, cut/fill heatmaps, progress-to-design measurements within the Propeller Platform, and more.

Is your project on track? Are you making money or burning cash from inefficiencies? Are there operational risks on site that need to be addressed?

With DirtMate, you have the data-backed answers to all of these questions, so you can monitor and manage your worksite effectively, every day. And when you know what’s happening on (and off) your worksite, you are better equipped to be proactive in your business and stay a step ahead of your competition. After all, a better measured and visualized site is a better managed site, right?

DirtMate Dashboard provides easy-to-understand production data and visuals

With access to daily production quantities, you can easily cross-check production data against load counts to assess actual vs. target volumes moved.

You also can easily review production activities across the entire worksite or in a specific area to more accurately bill for completed work, and quickly spot issues and take corrective action before they escalate.

DirtMate works on any machine, from any manufacturer. This means that you can easily view consolidated production information in one location. That’s right—mixed fleets are totally covered with DirtMate.

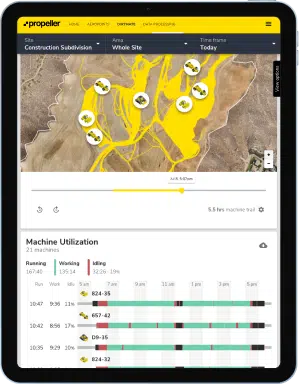

With the DirtMate Dashboard, you can see where your machines have been on site using a location timeline and even the paths they took while moving using location trails. Plus, you’ll get a handy breakdown of each machine’s utilization (working, idle, off) across your entire fleet, enabling you to proactively minimize errors and idle time.

You can’t manage what you can’t see. With DirtMate, you’ll be able to “see” everything happening on site, including how much dirt and other materials have been moved and when. You’ll also be able to quickly view machine usage, daily volumes, and much more—all from one, centralized, easy-to-use dashboard.

This visibility and accessibility of critical site data is a true game changer for contractors today. With DirtMate, you’ll have all the data you need, when and where you need it most

Empower field teams with access to site data in a convenient, tablet-friendly interface. With unlimited users available, everyone on your team will have access to the same data, enabling them to more effectively communicate, collaborate, and complete their work.

Plus, every team member will have access to 24/7 online support. When you need answers, you don’t have time to wait. We get that and we’ve intentionally built in the support tools you’ll need, regardless of time or location.

Quick look at DirtMate

DirtMate is an easy-to-install, cost-effective machine tracking system that integrates seamlessly with your drone survey data, enabling you to drive productivity, resolve disputes quickly, and understand exactly how you’re pacing on a daily basis.

With DirtMate affixed to your machines on site, you’ll be able to not only gather production volume data, but easily view and interact with that data using the DirtMate Dashboard.

No wading through data to find what you need. It’s all there in an easy-to-use format.

Disparate data is not only difficult and time-consuming to organize and use, it’s just plain annoying when you’re trying to operate a busy worksite.

With all of your production and machine usage data in one place, you’ll be able to quickly and easily identify problems or potential delays, investigate issues, solve disputes, and more.

With a complete picture of your worksite, you’ll be able to address potential risks or production delays before they become major issues. This kind of visibility helps you shift from putting those fires out to eliminating the cause of the problems to begin with, much quicker than you could if you were solely reliant on disparate data sources, potentially old or inaccurate data, and manual analysis.

Your survey data is only effective if you can rely on it to be available when you need it and, most of all, be precise. With Propeller, you will always have both. Think of it this way, every time you fly your site, you collect highly accurate data. Now, add another layer of site data gathered with your machines on the ground and you’ve just seriously leveled up your survey accuracy.

Staying ahead of the competition, completing jobs without wasting money, and building a strong reputation are evergreen goals for every contractor. With DirtMate and Propeller software, you now have a golden key to achieving those goals through better project oversight and worksite management.

Better data means you’ll not only be able to stay within budget and established timelines, but also accurately plan and forecast for the future, bill more accurately, and handle any disputes easily.

DirtMate can be installed on any moving vehicle or equipment on site—regardless of machine type or manufacturer—with a simple magnetic mount. This means there’s no need to drill, wire, or weld the system in place, keeping downtime and complexity to a minimum.

Skip the complicated processes or potential downtime to get DirtMate started on your machines. With one-button operation, you can be in the field and tracking data in seconds.

DirtMate comes equipped with two power options–solar panel and 12-24v DC input. With solar panels integrated into the DirtMate, you can enjoy wireless operation with ease. Or, plug them in for a quick charge in the office.

DirtMate uses a built-in GPS receiver to not only track machine movement on site, but also continuously survey the ground under the machine with RTK accuracy. The data collected is then sent back to the DirtMate base station for processing and local site calibrations.

Onboard IMU tracks machine vibration to determine usage metrics (e.g., idle, working, off). Gain full visibility over which machines are working and when and observe how they operate as a fleet.

DirtMate has a long-range transmitter that relays elevation and IMU data to a supplied network gateway. One, stationary DirtMate serves as the base station for data processing, making the whole process super easy.