UK-based Wills Bros Embraces Drone Surveying to Improve Road Construction Efficiency

Wills Bros is using Trimble Stratus, powered by Propeller. Trimble, the global leader in positioning technologies, was an early partner of Propeller. With SITECH, the global distributor of Trimble solutions, we work to deliver Trimble Stratus’s survey-grade drone data capabilities to contractors of all sizes in the heavy civil industries.

Wills Bros is partnered locally with SITECH UK & Ireland.

About Wills Bros and the Maybole Bypass project

Wills Bros, a family-run contractor based out of the UK and Ireland, has always sought to stay ahead of the digitization curve. Having embraced construction technology advancements like 3D surveying and machine control before most, Wills Bros has used its modern edge to win bids over more established contractors in the earthworks and civil space.

Recently, Wills Bros began work on the $40 million Maybole Bypass project in Scotland. Jonathan Wills, who was instrumental in the company’s recent investment in Trimble and Propeller, sat down with UK Plant Operators to discuss the obstacles they typically face on projects like these, and how Propeller has helped them overcome them.

Challenge: Quickly capturing accurate survey data for a large, complex road project

The 6km (∼ 3.75mi) project involves 900,000 cubic meters of earth removal and a further 15,000 cubes of rock that needs to be excavated and removed. In addition, Wills Bros is responsible for the construction of ten culverts to deal with water flow in the area.

For a project this size, surveying the entire site with traditional, ground-based GPS equipment would normally take six days, estimates Jonathan Wills. But considering the increased accuracy tolerance required for some of the structural elements involving the culverts, getting useful survey data from the ground would actually take weeks for this project.

For a contractor that handles both earthworks and civil work, accurately projecting the scope and pitfalls of a project is of particular importance. In order to efficiently price the project, schedule subs further in advance, and assess risks, Wills Bros needs survey data faster than they’re currently getting it.

Solution: Propeller PPK

“We’ve had a long-standing relationship with SITECH UK and Ireland, who’s been a great technology partner to us, first introducing us to the use of machine control technology on our dozens of excavators and motor graders,” explains Wills.

When he approached his SITECH dealer about potentially using drones for the Maybole project, he had only one suggestion: Propeller.

Wills Bros is using Propeller PPK, a complete drone surveying workflow that combines DJI’s Phantom 4 RTK drone; AeroPoints, our “smart” ground control points; offloaded data processing; and the Propeller Platform, a user-friendly drone survey software that allows them to measure their site using 3D models generated from their drone images.

The most obvious, initial benefit of adopting drone technology has been the speed with which they can collect accurate survey data. Before the union of RTK-capable drones and post-processing workflows, using drones to survey meant potentially sacrificing accuracy for speed.

Not anymore. With Propeller, Wills Bros was able to collect an initial earthwork takeoff of the Maybole project area in a fraction of the time it would have normally taken them—without compromising on survey quality.

“Savings on labor costs alone have been considerable given the fact that on so many occasions we can now obtain detailed project data within a second rather than sending a man on site to survey for information,” says Wills. “The drone comes in a backpack and is up in the air doing it’s thing within minutes. From the outset, the time savings are immense.”

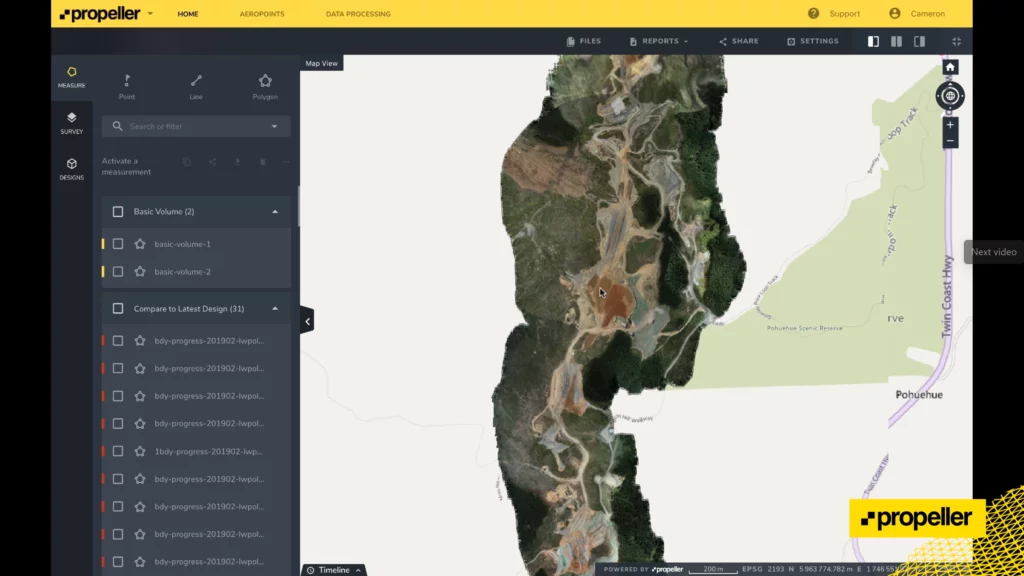

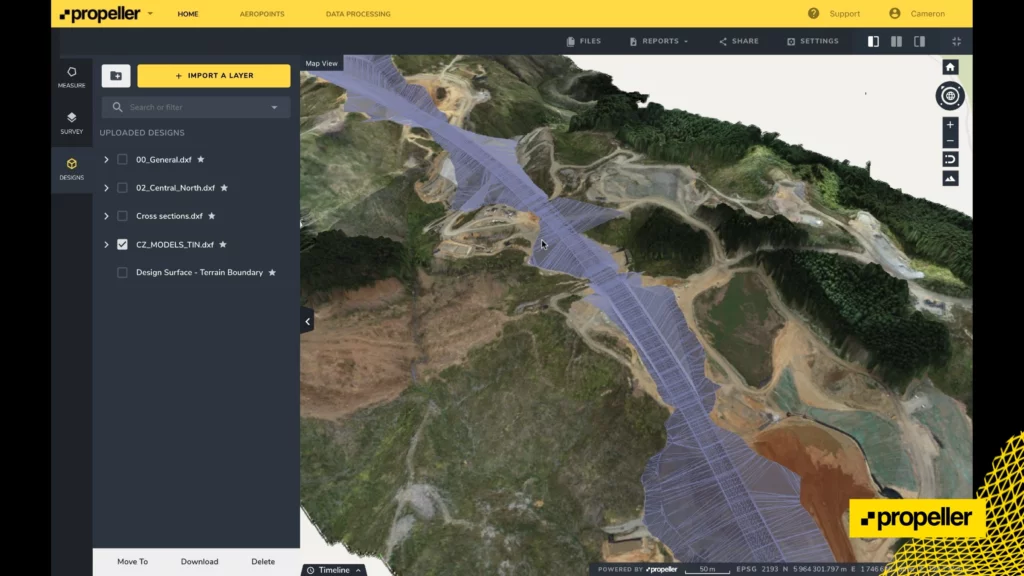

Once they’ve uploaded their drone and ground control data, Propeller transforms it into a 3D terrain model they can measure in the cloud-based Propeller Platform.

While other drone survey software tries to accommodate a broad category of users, the Propeller Platform is 100% focused on earthmoving and construction environments. Its suite of industry-specific measurement tools makes it easy for anyone—even those without surveying expertise—to jump on and gather actionable insights from their 3D site models, and share measurements and reports.

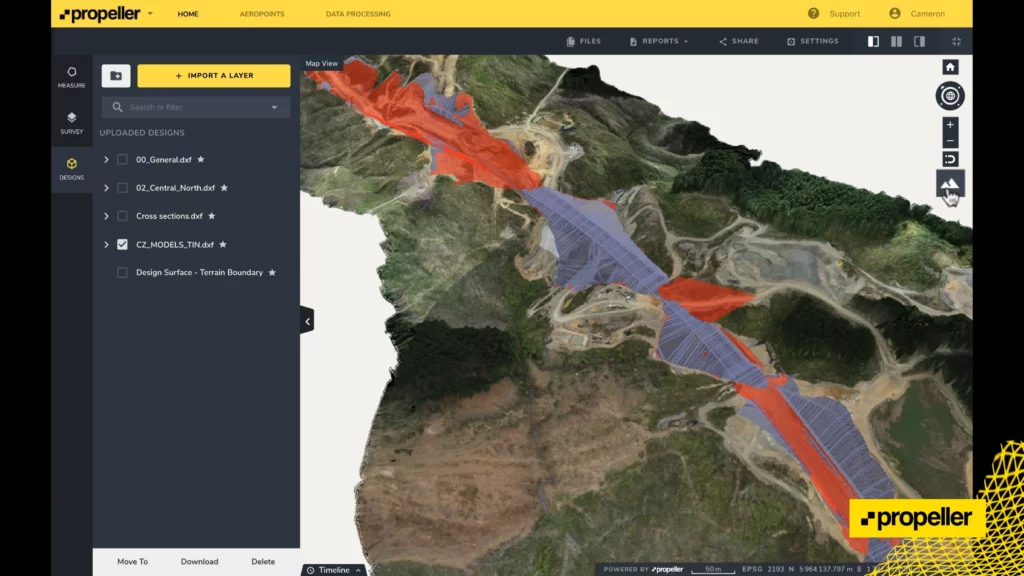

As the Maybole Project has progressed, Wills Bros has continued to fly their site regularly, uploading survey data to the Propeller Platform as they go. In addition to using multiple site surveys to track their progress over time, they’ve used uploaded design files of their final surfaces to measure how much work they have left to go.

“On the Maybole project, we can now accurately track our quantities progress against plan on a near-daily basis, says chief surveyor Pawel Szumski.” It really brings civil engineering into the BIM age, enabling us to share plans and data with clients and other contractors if required.”

Szumski hasn’t just been using Propeller to track earthwork progress overall. With visibility on the entire site, he’s been able to pick out specific trends and correct inefficiencies as he finds them.

“We can tell how much our machines are achieving at the touch of a button, says Szumski. Previously, we needed to send a surveyor with a GPS, which was time-consuming and slow. Now, we have actionable information in an instant. If an excavator is not performing, we can spot the issue early and explore the reasons why. It could be a technical error, the machine set-up, or the driver facing unexpected ground issues.”

“Prior to Propeller, we were acting on information that was already weeks out of date, says Wills. “Now, we’re ahead of the curve and can make decisions based on actual facts, not assumptions.”

Impact: Smarter project planning and better subcontractor relationships

“While we’re still learning about the true scale of its potential, it’s fair to say that Propeller has already made a huge contribution to our bottom line,” says Wills. “Having this level of data gives us great confidence and enables us to cost projects much more accurately. Moving ahead, our bidding process will become much more forensic, giving us the ability to quote for projects with real certainty.”

In addition to changing the way Wills Bros collects and analyzes survey data, Propeller has also improved their relationship with subcontractors.

“Reporting on progress across a complex project has always been time-consuming and sometimes contentious,” explains Wills. “If a sub has been tasked to lay X meters of drainage but is claiming to have done Y, this can cause friction. With Propeller, we can all see how much has been achieved at the touch of a button and pay the contractor accordingly. It’s so transparent and simple.”

Encouraged by the difference Propeller has made on the Maybole project. Wills Bros is already planning to deploy their new drone surveying workflow on other projects they’ve recently won, including the new A382 Corridor Improvement Scheme in Newton Abbott, and the N5 Westport to Turlough Road in the west of Ireland.

“Digital construction is definitely the way ahead for us,” says Jonathan Wills. “Undemanding the power of BIM and digital project management is a huge step up for us. We want to be the best in class within the earthworks and civil infrastructure sector—and our exploitation of new technologies such as Propeller is helping us to do just that.”

For more information on how to bring Trimble Stratus to your worksite, please contact SITECH UK & Ireland or your local SITECH dealer.

Keep reading:

Six Road Design Tools That’ll Lighten Your Load

A Case Study: The Journey From Simple Drone Surveys to Worksite Management (Part One)