How to Use Drones to Measure Stockpiles and Track Volumes More Accurately

Using drones to calculate stockpile measurements makes it easy to compare your current stockpile volumes to previous surveys and track site progress. You can also compare stockpile surveys to a final grade design file to calculate how much material you still need to add or remove.

With geo-referenced images captured by a drone flying above your worksite, you can use photogrammetry to generate a 3D map of your site with measurements accurate to 1/10ft (3cm). Drone survey visualization platforms—like Propeller—leverage that accuracy to take a variety of measurements, including stockpile volumes.

Using drones to measure stockpiles is quickly becoming a go-to surveying workflow for earthwork sites around the world.

For professionals in the mining and aggregates industries, stockpile inventory management is one of the primary use cases for drone surveying. Construction sites also use drones to survey their sites more quickly. The 3D maps generated from those flights collect actionable data, including stockpile volume calculations.

By flying a drone to measure stockpile volumes instead of sending someone out to traverse a dangerous site, site management can track their inventories and site progress in a faster, safer, more reliable way.

Let’s break down how drones and photogrammetry help worksites improve stockpile measurement workflows and streamline site analysis.

Want to jump ahead? Here’s where we’re going.

Why accurate stockpile volume measurements matter

Mine and quarry managers spend much of their time answering questions—or trying to answer questions—about quantities. How much is sitting in the stockyard right now? How much is going in the crusher or mill? What do you still need to extract? How much have you moved since last Thursday? What was its true value, and did you sell it for the right price?

When you have accurate site surveys at your fingertips—and thus full oversight of your stockpile inventory—finding the answers you need gets a whole lot simpler. Drone surveying workflows provide dependable, highly accurate stockpile measurements. And you can measure progress as frequently as you want to fly. This influx of stockpile inventory data enables teams to tighten up worksite operations, which can include everything from financial forecasting and supply-chain management to accurate reconciliation.

1. Prepare more accurate financial forecasts

Using drones to measure stockpiles is cheaper and easier than using traditional surveying equipment. It’s also far more accurate than “eyeballing” stockpile volumes. Drones put the power of frequent surveying in your hands and accurate stockpile volume calculation data at your fingertips.

Having reliable inventory numbers every month means drastically reducing future write-offs, which saves everyone money and boosts mine or quarry efficiency. Using drone surveying, “fluff factors” in inventory management have become a thing of the past. And with recent developments in photogrammetry, smart ground control points (AeroPoints), and drone hardware, you can generate models of your site with an accuracy tolerance of 1/10ft (3cm). That’s good enough for nearly anyone’s stockpile measurement standards.

2. Tighten up your supply chain

Knowing what you actually have on site allows you to better organize your supply chain. Report on inventory and supply quick asset snapshots, from when you need more stock to how much you still need to extract. If you’re your own supplier, easily plan when you need to start drilling and blasting based on current volumes. If you use an external supplier, you can plan purchases further in advance and calculate a more accurate budget.

3. Reduce costly write-offs

All quarries need accurate information on stockyard tonnage to fulfill work orders and remain financially solvent. But too often, big write-offs are par for the course. Even when they’re outrageously high, they’ve become an accepted status quo. Using drones to measure stockpiles gets you highly accurate volumes so you can reconcile any accounting discrepancies during an audit.

Using drones to measure stockpiles: the basics

First, fly your drone to capture site data

Before you can take a single volume measurement, you need to capture site data with a drone flight. There are a few ways to do this. “Drone surveying” basically means using a drone to take aerial photos of your site, combined with some form of GPS data and ground control to provide geographical context (aka coordinates).

There are two major drone surveying workflows to get the job done: GCP-based drone surveying and PPK drone surveying. (Find out why we recommend a PPK workflow here.)Flying a drone to survey your site is significantly faster—up to 10x faster, by some estimates—than traditional ground-based methods. It’s also safer for a drone pilot, whether that’s your head surveyor or someone else in your organization, to stand by and let the drone collect the data instead of walking the site themselves.

Next, let the photogrammetry software do the work

Once you’ve got the imagery and ground control data you need, it needs to be processed into your 3D model. For all but the largest operations, keeping a photogrammetrist on staff is cost-prohibitive. Similarly, processing the data in-house is a lengthy manual process that requires specialized software. Often, you also need a dedicated computer to crunch the numbers.

Propeller processes drone data for you with a 24-hour turnaround, so you can devote more time to other duties. You don’t just get the final model, either. You get easy access to data outputs: point clouds, digital elevation models, and more. These can be exported for use in other GIS and CAD programs.

How to use drones to measure stockpile volumes for quarries or mines

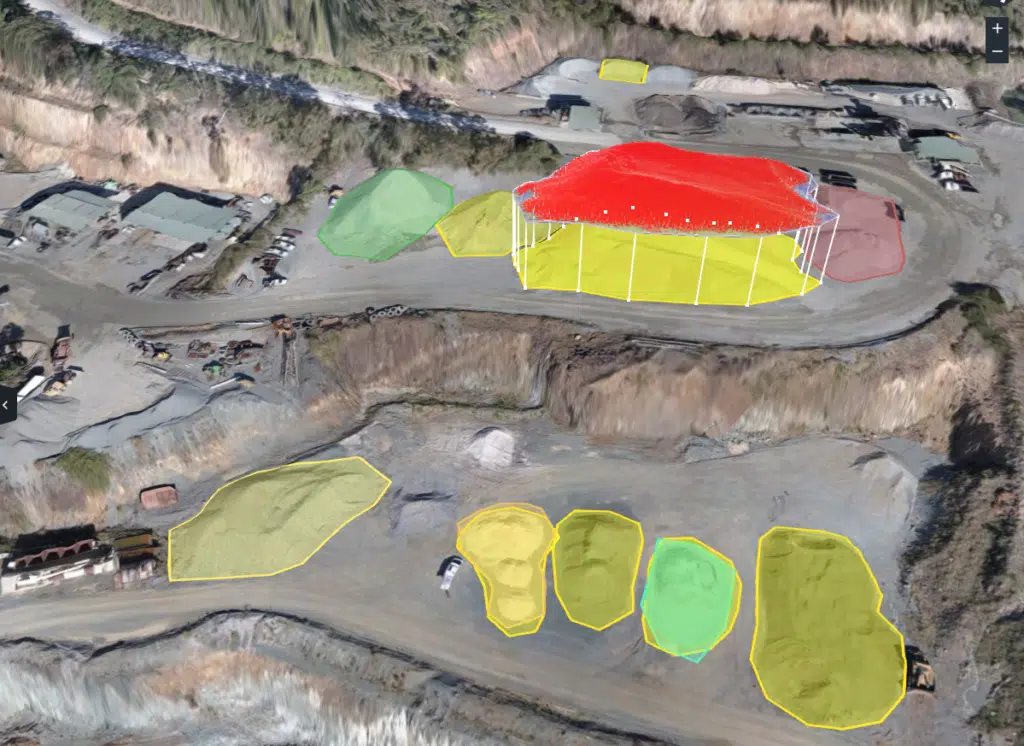

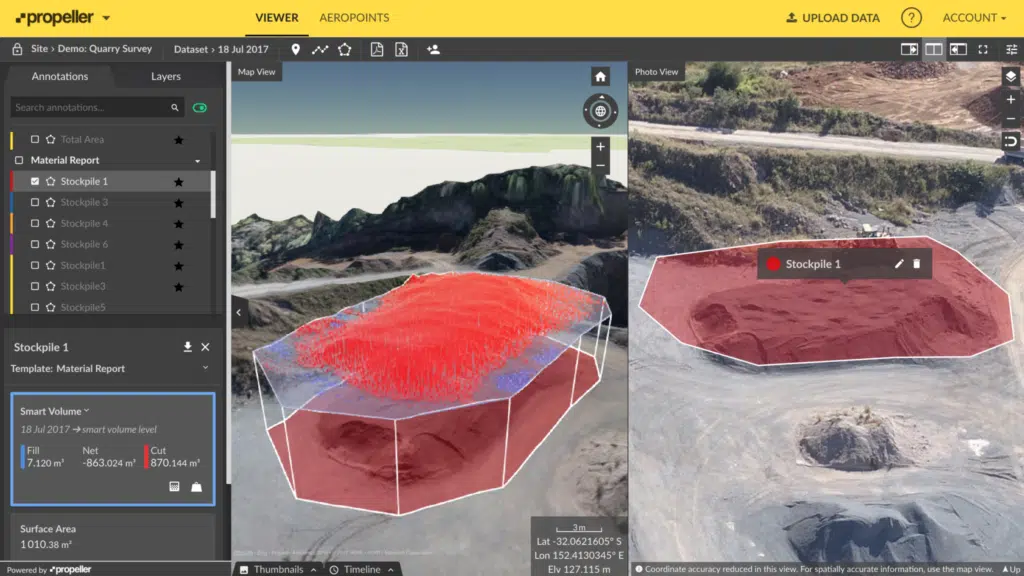

Once you’ve generated your model, you can analyze your site using drone data visualization software like the Propeller Platform. Measuring the volume of a stockpile in Propeller is as simple as drawing a boundary around it with a few clicks.

You can quickly make the types of comparisons site managers use to measure progress and keep stock of material inventory. But the measurement methods you use will vary depending on the information you need.

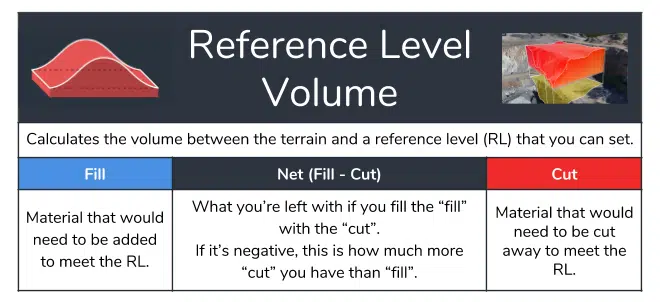

Option 1: Measure volume from a reference level. Set the baseline to the desired figure and calculate stockpile volume from that level up.

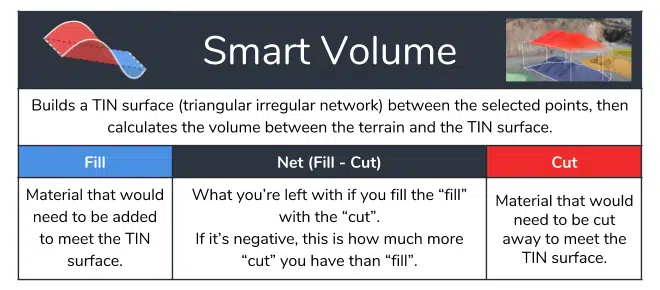

Option 2: Measure using a smart volume, and let the computer do the work. For a smart volume, the platform extrapolates where the base of your pile is and calculates a total volume from there.

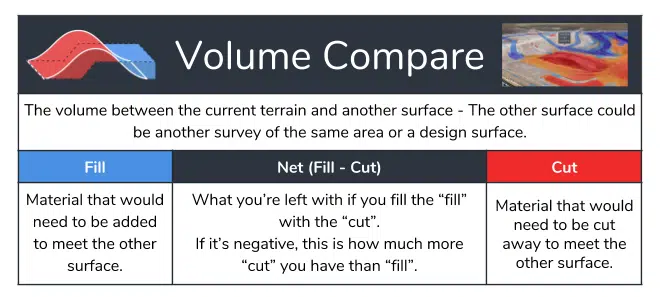

Option 3: Compare volumes between two surfaces. Compare survey to survey in order to see progress over time. Or, compare the current surface to a final grade design that you uploaded to Propeller.

Using the stockpile volume calculator to determine the value of stockpiles

Once you have a stockpile volume, you can enter its known material density into our stockpile volume calculator. This tool will help you determine the tonnage and cost of any stockpile using a simple stockpile volume calculation.

For example, let’s say you want to find how much material has been added to or removed from a stockpile since your last drone survey.

Simply select the Polygon tool and draw a line around the base of the stockpile. In an instant, Propeller will take the thousands of recorded height samples (your digital elevation model) within the boundary of this polygon.

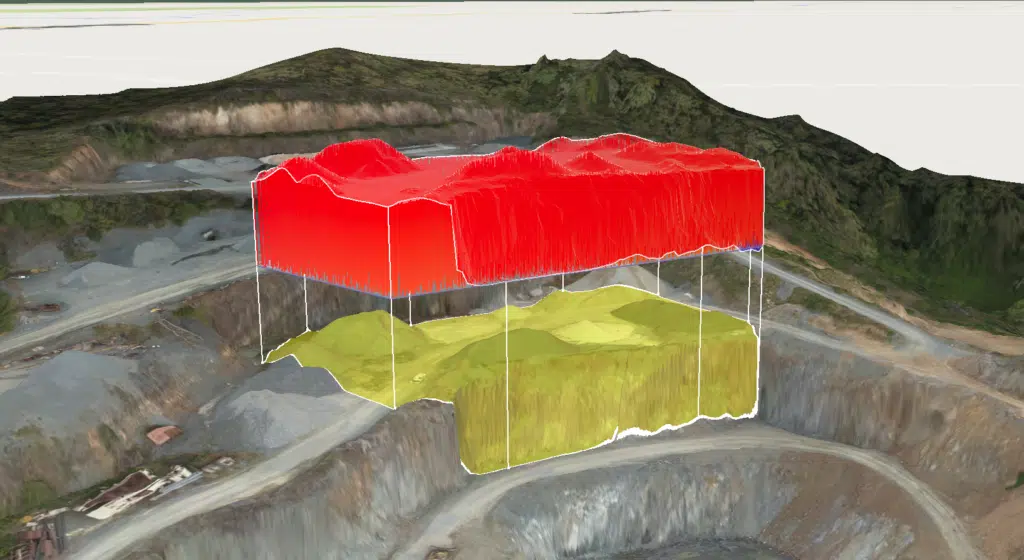

Next, Propeller compares these height readings to those from your previous survey. Volume changes are expressed as Fills where material has been added, or Cuts where material has been removed.

The Net value is the difference between the Cut and Fill. When measuring stockpile volumes, the Net figure will be more or less synonymous with the Cut, since you are measuring one mound of land above the base elevation.

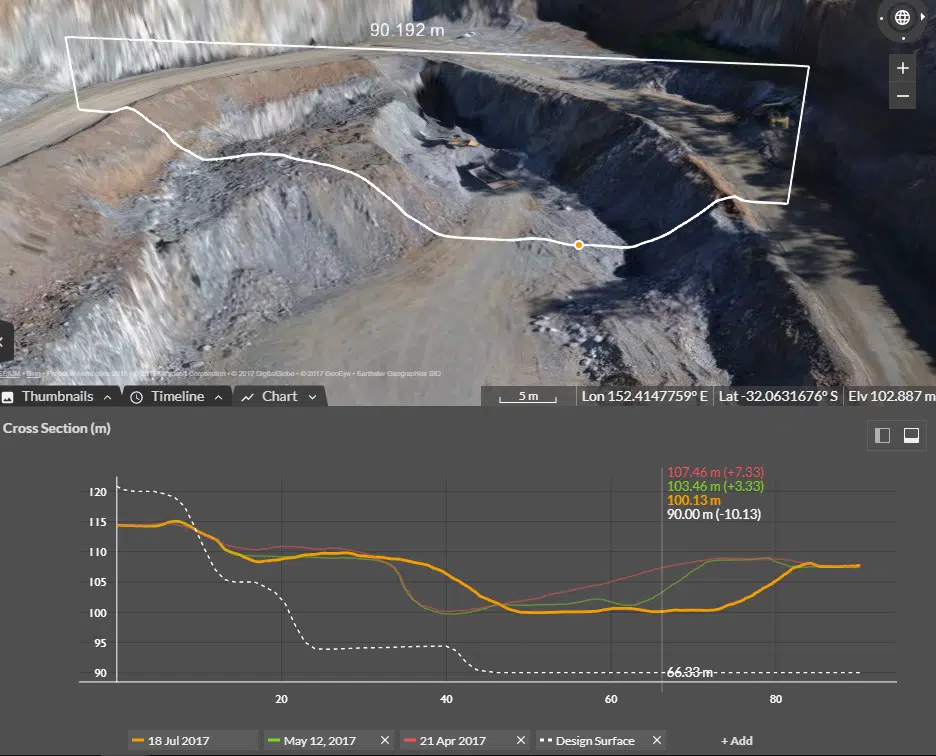

It’s also possible to visualize stockpile changes as a cross-section. Just use Propeller’s Line tool to generate a graph depicting the elevation change for each point on that line.

The measurement process for pit and stockyard volumes is similar to that of quarries and mines. However, having the correct grade blends is essential to your success.

Insufficient input grades are often discovered after the fact, when the final material doesn’t add up to pre-processing records. Instead of backtracking, use Propeller to monitor stockpiles before something goes wrong.

We know landfill surveys can be difficult, too. It’s nearly impossible to send someone out to walk those piles. Drone surveying can capture the data you need in hours, not days, without sending someone to walk over dangerous piles.

How to report on your stockpile volumes

48% of aggregates and mining professionals who responded to our 2020 Earthwork Report listed “material moved” as the metric most important to operational efficiency. That came as no surprise to us. We know that keeping track of material inventory at every stage of a project is critical to smart decision-making on mines and quarry sites.

But having that data available to your organization is only useful if it can be shared in a contextual, easy-to-understand format. For instance, financial recordkeepers and auditors probably don’t need to know the tonnage of a stockpile if they have its volume and dollar amount.

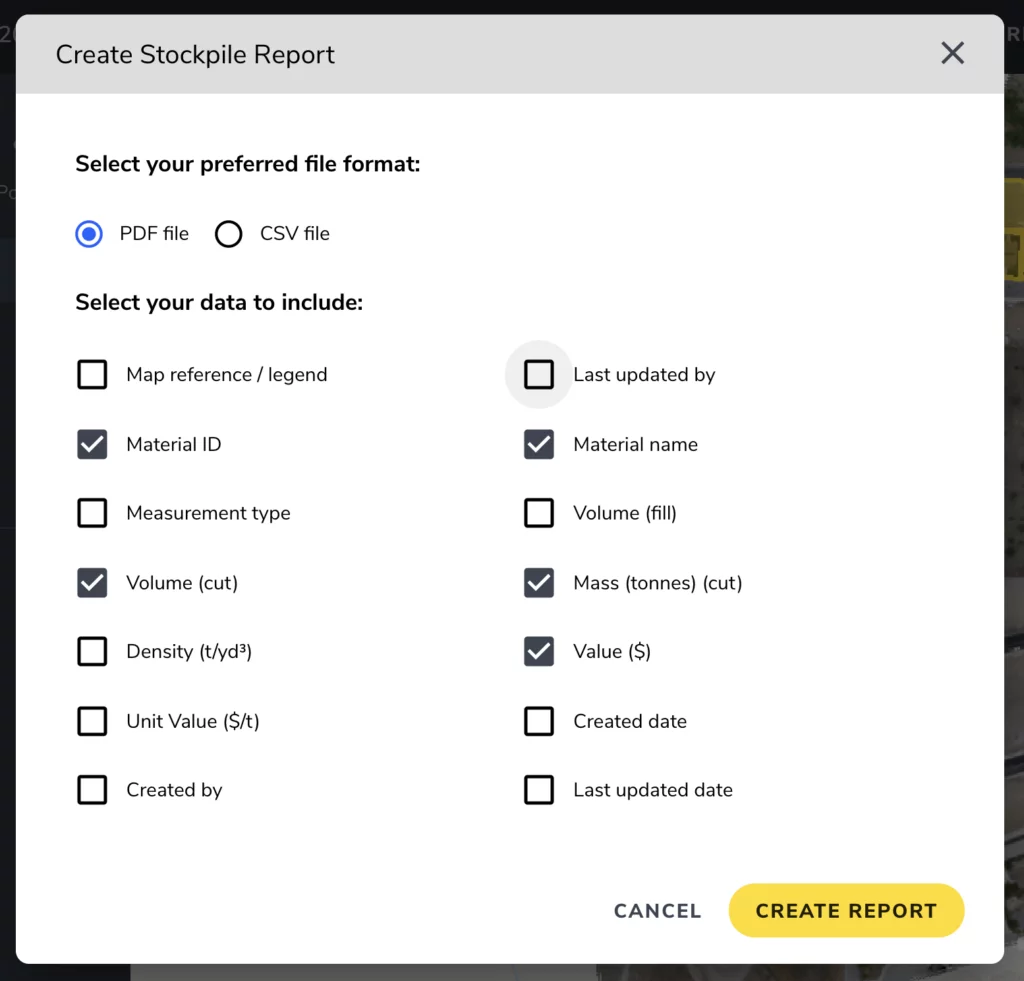

Propeller’s inventory reporting for stockpiles feature empowers platform users to export customized data in either a PDF or a CSV so they can pull it into another accounting or site management program.

3D blast planning and other drone surveying use cases for quarries and mines

Using drones to measure stockpiles is not the only application for mines and aggregates sites. Before you can build up your stock, you need to extract it. Making decisions with the most up-to-date and reliable information is critical for any site manager, especially when planning and executing blasting work on a mine or quarry site. Keeping your site survey and bench level plans updated (not to mention accurate) can dramatically improve blast results and significantly reduce drilling and blasting costs.

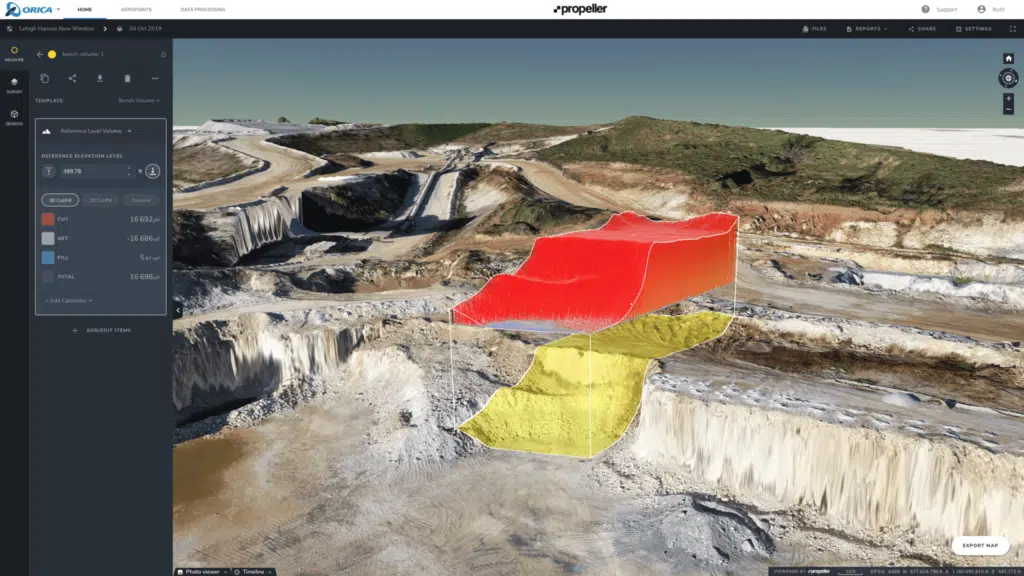

When planning blast works to fill a specific customer’s order, you can easily identify a volume on the 3D model using the Volume to Reference Level measurement tool. Simply draw a shape around the blast area, set the bench level to “blast to,” and the computer will crunch the numbers from there.

These images also provide a good source of data for visual assessment of blast results like muckpile shape, back damage, distribution, and fragmentation. Plan your post-blast logistics using the fragments’ size and location data. You can also measure pile volume and fragment size, add annotations, and share blast reports with stakeholders directly from the Platform.

Using Volume Compare, you can compare the blasted volume against the plan, making it easier to verify whether the right amount of material was extracted. If you have any design or linework, you can overlay that into the model to help with accuracy and quality—and ensure you’re not leaving resources in the ground.

Want to learn more about how you can use drones to measure stockpiles and streamline your inventory management? Download our guide to Stockpile Measurement and Reports with Drone Surveying.