Happy 3rd Birthday, Propeller PPK!

It’s almost the end of October, which marks a very special time for us here in the Propeller offices. No, we’re not talking about Halloween—though we love a good excuse to watch scary movies and eat candy. October 30 marks three years since we first launched Propeller PPK, an industry-leading drone surveying workflow.

When we call Propeller PPK a game-changer, we aren’t just tooting our own horn. Brian Leppo, the GPS Coordinator at Conewago Enterprises, recently told us, “Propeller has changed the way our site department does business, and we have tried multiple platforms and drones. The Propeller PPK workflow changed the game for us.”

In celebration of the surveying workflow that has made a massive difference to so many of our customers over the past three years, we thought we’d throw PPK a birthday party—in blog post form, anyway. Read on to learn more about why PPK makes such a big difference for our customers, some major milestones we’ve hit this past year, and how you can leverage PPK on your job site.

Meet Propeller PPK

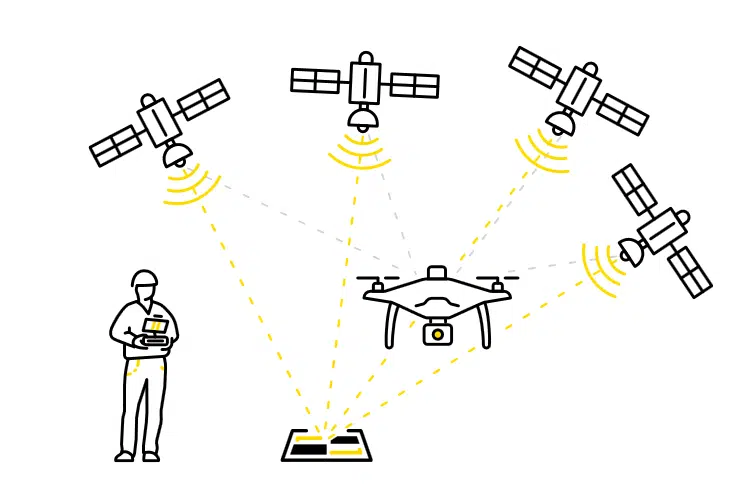

If you haven’t met Propeller PPK yet, allow us to introduce you. PPK isn’t hardware or software—it’s a workflow that uses RTK-enabled drones to return highly accurate survey data from images captured during flight, even on large or remote worksites.

We’ve written a lot about PPK lately, so if you’re curious about how it works, we’ve got some great resources to get you started:

- How PPK works

- PPK vs RTK—what’s the difference?

- How AeroPoints and PPK work together

The PPK (post-processing kinematic) workflow eliminates almost all of the hassle for teams who want a quick, accurate view into the state of their worksites. Just place at least one AeroPoint on the ground nearby, push a button to fly a pre-programmed path through your site, and keep your drone in the air for at least 10 minutes. Upload your flight data, and within 24 hours you’ll have an accurate 3D map of your worksite. Simple as that.

Loren Otto, co-founder of AirBorn Insight, made sure to mention the benefits of PPK over RTK when he sang PPK’s praises: “We love the Propeller PPK workflow. It’s very reliable, and we know that we’re going to get a good result. It’s more reliable than RTK, which sometimes drops out.”

Major PPK milestones

As a customer-first business, we didn’t release PPK and then spend the next three years resting on our laurels. Far from it—we’ve spent that time gathering customer feedback to make PPK even better.

Here are just a few of the improvements we’ve implemented in the past year alone:

- More drone options: We’ve expanded the number of recommended drones compatible with PPK. In addition to our longtime recommended quadcopter, the DJI Phantom 4 RTK, we’ve added partnerships with the VTOL WingtraOne and the heavy-duty DJI Matrice 300.

- New, improved AeroPoints: AeroPoints are a critical part of the PPK workflow. This summer, we announced the next generation of AeroPoints. The update includes a new WiFi chip, dual-frequency GPS, upgraded battery performance, and a companion app.

- Propeller platform upgrades: Think of the Propeller Platform as the gateway to your PPK data. Once we’ve processed your flight data and turned it into easy-to-use 3D maps, the Platform is where you’ll view maps, determine measurements, and interact with your data directly. We’ve rolled out some major platform upgrades this year, including composite surveys and a design-to-design comparison tool.

How PPK is making a difference on worksites worldwide

To say that the list of uses for Propeller PPK is “endless” would be an exaggeration—but not by much. It’s been a sincere pleasure to see the results our customers get with Propeller PPK across a wide range of use cases.

Take Charles Avery, a customer from Lindamood Demolition, who told us, “Our very first flight we discovered 5000-6000 extra yards of material, which more than paid for the drone setup. It’s a really good tool to see if our subcontractors’ data is as accurate as they think it is. It makes for very useful comparison data.”

We’ve seen customers leverage the surfaces generated by Propeller PPK to enable better earthwork takeoffs, haul road maintenance, and cut/fill or material quantities calculations. They’ve used it to improve safety, resolve disputes, or simply shore up their bottom line.

Here’s a real-life look into how some of our customers use Propeller PPK today:

- Family-owned Fiore uses PPK to manage large projects like Red Rocks, which involved moving 5 million cubic yards of dirt in one year. “Coming from tougher software to work with, Propeller was super simple,” says PM Kyle Miller, who has worked with CAD software in the past. “It’s as easy as drawing a line or boundary around something, and it’s going to give you a quantity.”

- Matt Bousman, president and CEO of Whitaker Construction, is impressed by the return on investment he’s seen since investing in Propeller PPK. “A year ago, we were barely considering this because of the cost,” he told us. “Now we’ve implemented a full drone program.” His company has been taking on landfill construction projects, so measuring cut/fill volumes accurately is make-or-break for his business. “We’ve been able to figure out where the dirt is, where it needs to go, where it’s coming from,” he said. “It’s accurate enough for decision-making, and it’s far most cost-effective for me to do it [using PPK] than having an auditor or surveyor out there.”

- UK-based Wills Bros has been using PPK to save on labor costs and get regular survey updates in a fraction of the time they’re used to. “Savings on labor costs alone have been considerable, given the fact that we can now obtain detailed project data within a second rather than sending a man on site to survey for information,” Jonathan Wills told us. “The drone comes in a backpack and is up in the air doing its thing within minutes. From the outset, the time savings are immense.”