Drone Surveying Misconceptions: lidar vs. Photogrammetry

Did you know there are several types of drone surveying? Drones are versatile and can be outfitted with very different kinds of technology. Two of the most common types are lidar and photogrammetry, which we’ll review in detail in this post.

If your work requires a bare earth survey on land cluttered with vegetation, you might have heard that lidar is the best option. But new advances in software have enabled drone photogrammetry to achieve the same results with more affordable equipment.Further, the operational ease of use for photogrammetric surveying is much improved, and you don’t need special training to survey with a drone. Depending on your location, you just need to get certified by your country’s aviation authority. In the US, you need a Part 107 from the FAA. In Australia, you need an ARN from CASA.

Want to jump ahead?

What is lidar?

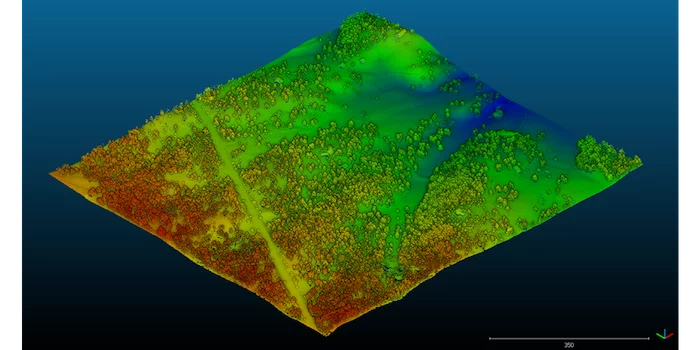

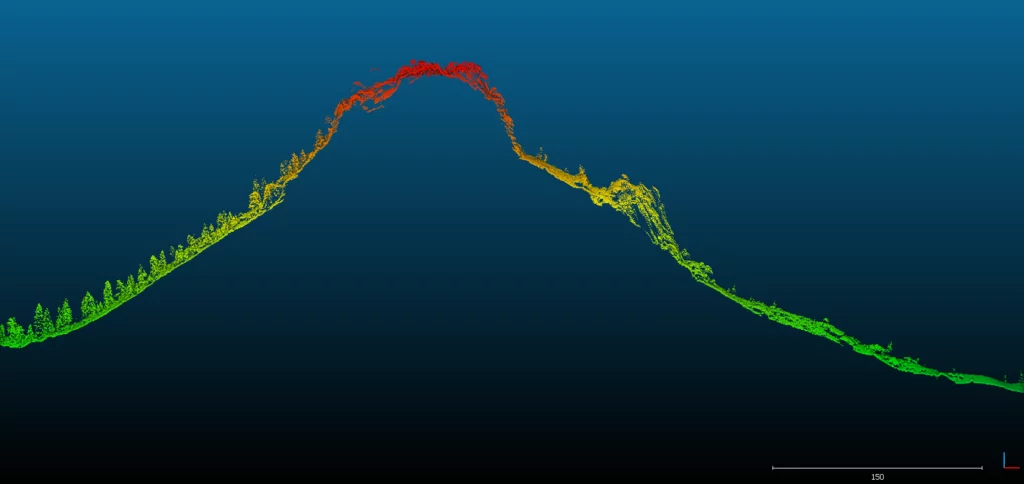

Lidar was invented in the 1960s and stands for “light detection and ranging.” It measures distances by sending laser pulses at a feature (a tree, a cliff face, or the ground itself) and measuring the reflected pulses with a lidar sensor. With some trigonometry, you can calculate distances very accurately—and with many, many points of reflection (think millions), you can reconstruct a point-based model of the terrain. These models are also known as lidar point clouds.

Lidar is similar to sonar or radar, which use sound and radio waves respectively to map surfaces and detect objects. In most cases, lidar uses infrared light. Lidar sensors can be mounted on planes, tripods, automobiles, and drones. (This technology is sometimes called 3D laser scanning, since it’s ultimately used to generate a 3D point cloud.)

How photogrammetry differs from lidar

Lidar is a direct measurement—you’re physically hitting a feature with light and measuring the reflection. Drone photogrammetry uses images captured by a drone-mounted camera to reconstruct the terrain in an accurate 3D model using image overlap and sufficient ground control.

Learn more about the science of using photogrammetry to turn drone images into image point clouds and 3D maps in this blog post.

The main difference between lidar and photogrammetry is, of course, how they capture their data. But many people are still under the false impression that photogrammetric surveying doesn’t yield absolute accuracy when it comes to bare earth.

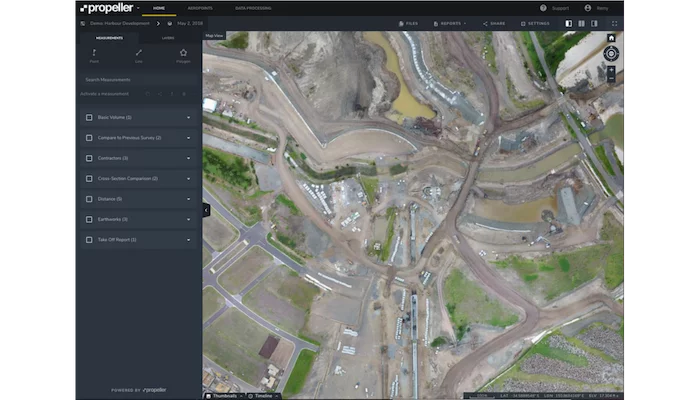

With the right filter settings, like the bare earth filtering in the Propeller Platform, you can get the data you need and retain the valuable visuals of a photogrammetric survey if your vegetation cover isn’t extremely dense.

Lidar produces a point cloud-like image, whereas photogrammetry uses photos of the real site to create a fully 3D visual model of the actual terrain.

When to use lidar vs. photogrammetry

Like all technology, lidar has use cases that it’s especially well-suited for. If you’re surveying land with dense vegetation where light pulses can still penetrate between branches and leaves, lidar yields high vertical accuracy.

This is a significant advantage over photogrammetry, as photogrammetric surveying will only produce high vertical accuracy when there is sparse vegetation on site. While lidar does have similar limitations, it can penetrate areas with up to 90% vegetation under good conditions. (Photogrammetry sits closer to the 60% mark.)

If you’re consistently working on sites with vegetation denser than 60%, and have your own in-house processing software with someone to run it, lidar may be worth the investment for your business.

As you might imagine, all these capabilities make lidar a fantastic solution for the forestry industry. There, it has the dual advantage of mapping denser vegetation and large tracts of trees. It’s also great for vast, watershed-scale surveys via plane.

But when it comes to the broader surveying needs in the construction, mining, and aggregates industries, photogrammetry is the more affordable solution, with great accuracy and ease of use that suits most teams.

Debunking common lidar myths

We’ve spoken to many customers investigating lidar surveying for their sites—here are the misconceptions that keep popping up.

Lidar can see through vegetation

False. Lidar isn’t the same as X-ray vision. Lidar penetrates the spaces between the foliage, trees, or other flora. It can map the ground covered with denser foliage, which is a point over photogrammetry. But note that should your site be extremely dense with vegetation, you might have to send a surveyor out to shoot a few points under the canopy.

Lidar is the most accurate surveying solution

False. Photogrammetric surveying is just as accurate as lidar. With workflows like Propeller PPK, you can get accuracy of 1/10ft with a few simple tools. (Check out our whitepaper for more information on how we get this level of accuracy.)

With both photogrammetry and lidar, accuracy in the air is affected by the drone’s movement, not just the sensor itself. So, no matter which technology you’re using, you’ll still require data correction.

Benefits of photogrammetry in surveying

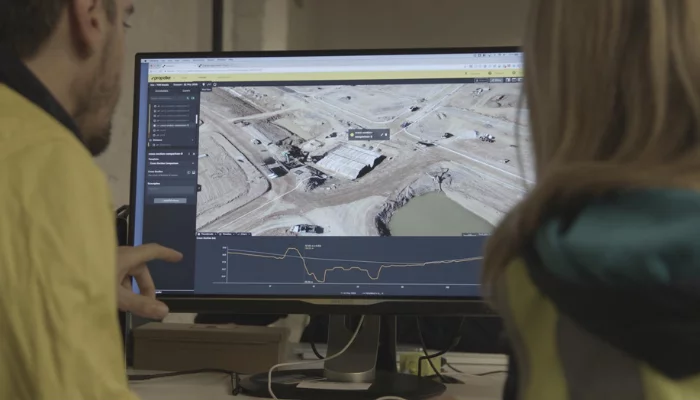

When you build site surveys with photogrammetry, you get accurate 3D models that are as true to the real world as possible. With data visualization software like the Propeller Platform, you also get 3D models of your site that are fully measurable and easily navigable.

Lidar gives you a point cloud, but because photogrammetry stitches photos together to create your model, you get the visual details of every feature on your site, taking abstraction out of the conversation.

Think of it like this: lidar produces an elevation set, while photogrammetry gets you elevation plus visuals.

Photo-based models can also be used to verify what feature you’re seeing. When it comes to fine-detailed surfaces and features, lidar can be unspecific—you might find yourself unsure about what exactly you’re seeing.

For example, if you’re surveying a cliff face to evaluate the safety risk, it might be easy to see a broadly articulated tree on the model, but smaller flora can be hard to detect and easily mistaken for rocks (as in the image below).

Affordability and lower replacement cost

One of the most significant differences between photogrammetry and lidar is price. A drone-based lidar system can set you back $60,000 or more for the hardware alone. Propeller’s recommended drones start at a few thousand dollars and are widely available.

Lidar’s up-front cost also translates down the line. It’s more financially risky to put a five-figure drone into the air than a four-figure drone.

If you damage or crash a lidar drone, you need to replace it at full cost. And due to the specialty manufacturing and involved setup process, you likely won’t be back in the air right away.

With a Propeller-recommended drone, you can often buy a repair package for a few hundred dollars and have a replacement drone on the way to you immediately.

Drone setup and calibration

When it comes to user-friendliness, both lidar and photogrammetry have pros and cons.

Lidar doesn’t use a camera, so you don’t need to calibrate camera settings for environmental conditions like you do on a photogrammetric drone.

But lidar’s hardware can be challenging to set up—calibrating for the center of gravity and measuring the lever arms requires a tremendous amount of precision.Ground control is a necessary part of surveying, no matter which technology you’re using. In the past, lidar had the advantage of not requiring ground control points, which saved legwork and time. However, with Propeller PPK, it’s essentially the same setup workflow as lidar: just set up your base and fly.

Data capture and processing

The time you’ll expend on drone-based lidar and PPK drone surveying is comparable. Neither system requires a traditional ground control setup—just a base station on the ground for data correction.

In some ways, lidar is easier to process simply because it is less detailed than photo-based datasets. However, there is no cloud-based lidar processing on the market at present; you have to do it yourself. That requires in-house software and computing hardware, as well as a specialist who can adequately render and correct all of that raw data.

Cloud-based data processing saves you time, money, and hassle

With Propeller, all you need to do is upload your drone images and base station data, and tell us what coordinate system you’re working in—we’ll handle the rest. Our processing software delivers you an accurate 3D site model 24 hours later.

Whether you base your decision on cost, user-friendliness, or the visual output of your survey, we recommend photogrammetry for 95% of cases.

Read more:

How Propeller PPK Improves GCP-based Drone Surveying