A Case Study: The Journey From Simple Drone Surveys to Worksite Management (Part Three)

Integrated Sustainability is using Trimble Stratus, powered by Propeller. Trimble, the global leader in positioning technologies, was an early partner of Propeller. Our teams work closely together to deliver Trimble Stratus survey-grade drone data solutions for the heavy civil industries.

Be sure to check out Part 1 and Part 2 of this case study series.

Barry Prystawski is the director of technical execution and construction at Integrated Sustainability, a specialty turnkey infrastructure delivery firm that provides water, waste, and renewable energy solutions with an emphasis on environmental best practices and sustainable construction.

To Prystawski, every aspect of his job comes down to one thing: efficiency. In essence, Prystawski is responsible for making sure that everyone in the engineering department and on the construction site knows what they need to be doing, and that they have the resources and information to do it right.

To keep everyone else running at peak efficiency, Prystawski is constantly seeking out ways to optimize his own workflow. Obstacles Prystawski has run into in this role include:

- Spending too much time interpreting information from multiple sources, delaying critical decision making.

- Sharing data and collaborating with colleagues across multiple departments

- Rectifying errors that went undetected

Introducing drone surveying to the workflow

So, when Kris Kwiatkowski, Integrated Sustainability’s Geospatial Manager, pioneered a drone survey program at the company, Prystawski was excited to see how access to more consistent, reliable survey data could make his job—and everyone else’s—easier.

Kwiatkowski uses our Propeller PPK drone surveying workflow to map Integrated Sustainability’s sites, which includes:

- Phantom 4 RTK: DJI’s RTK-enabled drone

- AeroPoints: Smart ground control points

- Trimble Stratus: A data analytics, processing, and 3D mapping platform

As Trimble customers, Integrated Sustainability views and processes these models in Trimble Stratus, a specialized version of the Propeller Platform that integrates seamlessly with Trimble Business Center.

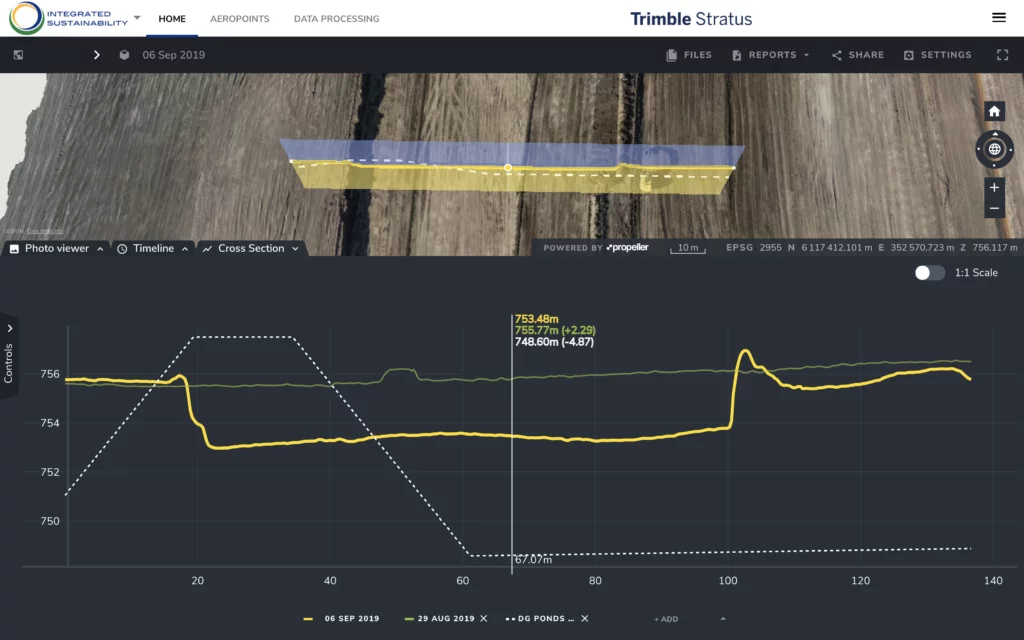

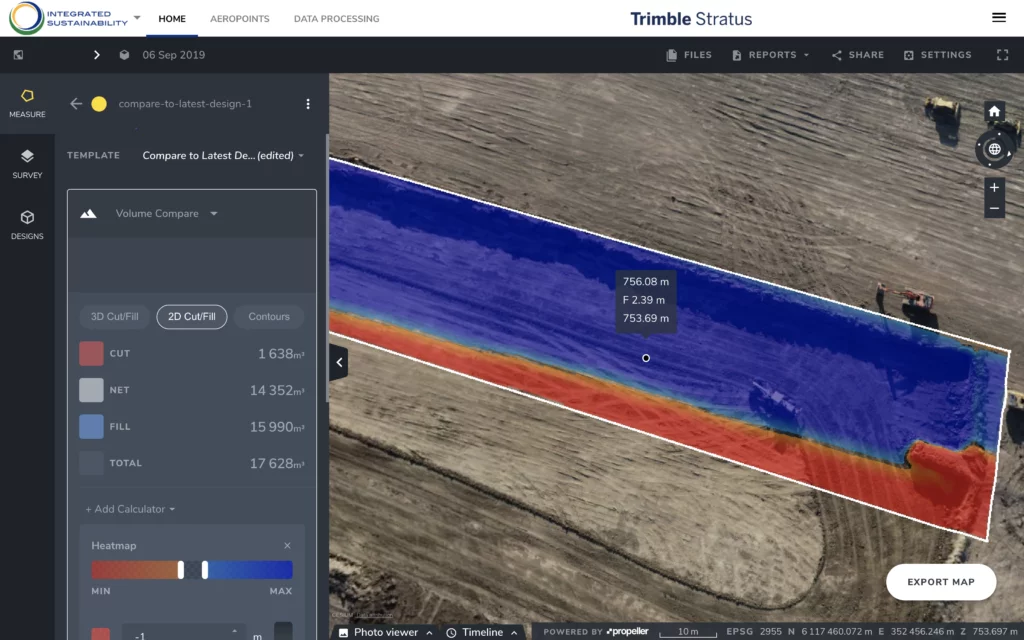

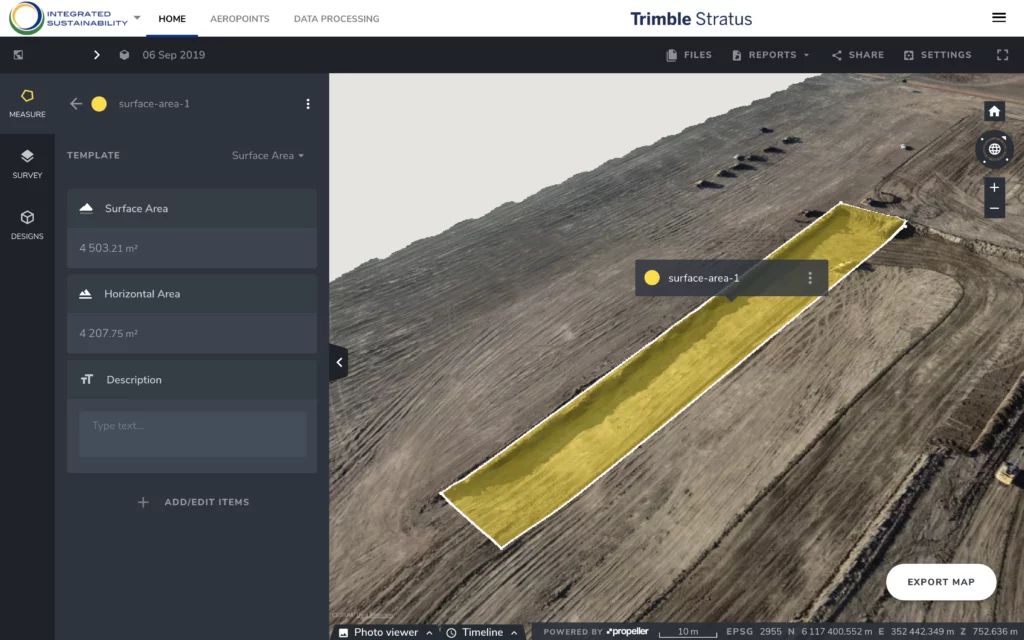

Prystawski relies on his geospatial manager to validate the drone data and filter the terrain to make it usable, but, once the surveys are in the platform, Prystawski logs in and uses a suite of industry-optimized measurement tools himself. He’s able to do things like check cut/fills and measure current progress against subgrade surfaces against the final design, without having to consult a specialist like Kwiatkowski.

Not only does that remove the geospatial manager as a bottleneck to information for Prystawski, it also prevents Prystawski from being a bottleneck for everybody else. Today, engineers, construction managers, and others in the organization can get the information they need by going into the platform themselves—freeing up Prystawski’s time, while accelerating their own workflows.

Better visibility for every stage of a project

With access to more frequent, faster surveys, Prystawski is able to determine whether projects are running on schedule. He’s also able to use the most recent data, along with historical surveys, to forecast future work.

Having an idea of where a project will be a week or month out helps Prystawski plan the next phases. It makes everything from budgeting to resource logistics to subcontractor scheduling a more precise operation.

On the engineering side, Prystawski has been able to use surveys in the platform to collaborate with his team on a host of preliminary project stages. These include site selection and setup, environmental assessments, resource logistics, and more.

It’s also given the engineering department a more convenient way to understand the impact of a design change mid-project. They can easily upload new surfaces to the platform, compare them against current progress, and decide whether to move forward with the change.

Access to interactive, photorealistic site maps has proven a valuable asset when communicating with clients, as well. In meetings, Prystawski is able to show clients 3D models and orthophotos of their sites by pulling them up in the platform. He’s also able to export reports with helpful visualizations and send them to clients.

Less data interpretation, more actionable data

Before he was able to turn to Trimble Stratus, Prystawski was relying on a hodgepodge of different sources, to get an idea of site progress. These sources included a variety of field reports from different personnel, context-less non-georeferenced photos, and phone calls with people on site.

Now, Prystawski has one, easily accessible, centralized source of truth that he can turn to. No more second-guessing the data. No more keeping track of multiple reports. No more reconciling contradictory information.

Prystawski estimates that with this new workflow, he is able to figure out in 15 minutes what previously took two hours of information gathering and analysis to understand.

And with access to daily drone data, Prystawski is able to catch potential mishaps on site more quickly as well. If Prystawski notices any discrepancies between the surveys and what his plans show, he’s able to send out a surveyor to do ground measurements. From there, he can determine whether there was an error in the data or whether dirt was moved incorrectly.

Having visibility on potential issues means Prystawski can resolve them more quickly, keeping the project on track and under budget—and bolstering Integrated Sustainability’s reputation as an efficient, cost-saving project execution machine.

Want to see how Propeller works? Unlock a demo here.

Related resources:

A Case Study: The Journey From Simple Drone Surveys to Worksite Management (Part Two)

Family-Owned Business With Large Footprint Sees 10X ROI from Drone Program