Women in Mining Q&A: Martin Marietta’s Lynn Kern

What does new technology adoption, efficiency improvements, and overall industry progress have in common? You. These things are only achieved because of the hard work of industry leaders, technology champions, and everyday people working in construction, mining, aggregates, and waste management.

With that in mind, we want to showcase these individuals and learn how they’re changing the way their companies work for the better. Today, we speak to Lynn Kern, a mine planner at Martin Marietta.

Tell us about your company and your role there. What do you do?

Based in Raleigh, North Carolina, Martin Marietta is a leading supplier of building materials—including aggregates, cement, ready-mixed concrete, and asphalt.

Our teams supply the resources necessary for building solid foundations that allow our communities to thrive. Literally, our materials build the roads, homes, schools, offices, and hospitals that make up those communities.

I joined Martin Marietta three years ago and currently serve as manager of mine planning for the company’s Mid-Atlantic Division, based in Greensboro, North Carolina.

What’s your career background?

As an engineering student at Virginia Tech, I excelled at math and science and was pretty sure I wanted to focus on those areas as I built my career.

During my sophomore year, I asked a counselor about the different types of engineering available to me. She told me about every discipline except mining, which she didn’t know much about, but she had “heard good reviews.” Admittedly, I did not know much about it either. Now I know how critical the materials are, but when you are 19 or 20 years old, you don’t appreciate the materials that built the roads you take to class every day.

So, that same day, I reached out to the head of the university’s mining engineering department. After hearing about the small class sizes, 100% job placement rate, and ability to work in the field, I signed up and never looked back.

Why did you look into using drones as a survey tool on your worksites?

Traditionally in mine planning, we use topographies on a daily basis. Before drones, we used datasets that came from manned aircraft, which proved costly and it sometimes took up to three months to get the data back.

We started using drones primarily to get data faster than we could with previous methods. Today, while it depends on the project, I can fly as often as five times a month and get data that’s pretty close to real time.

What was the learning process like starting with this new technology?

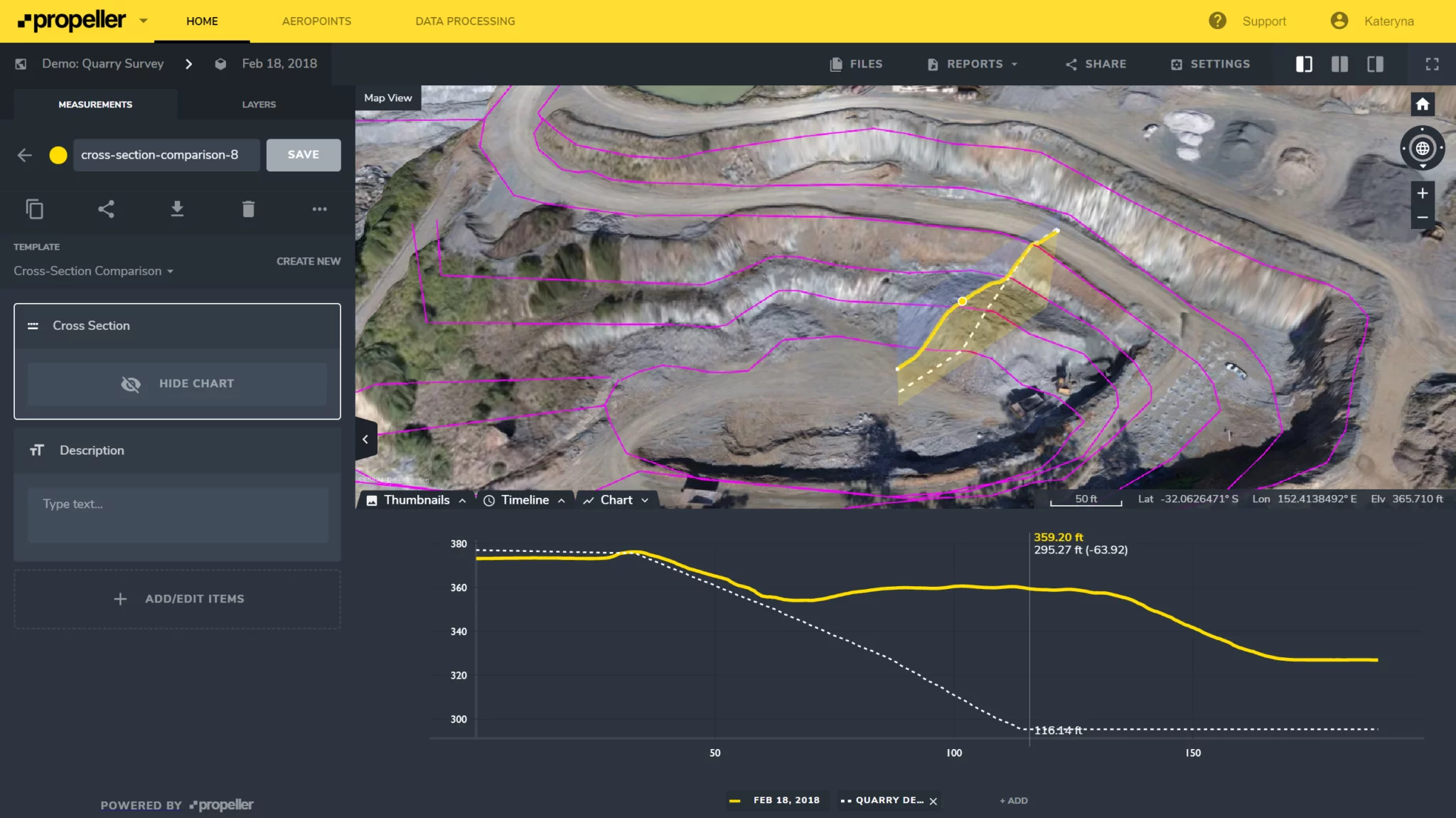

I’ve been very pleased with the learning process. Compared with other mine planning software packages I have used, which require a technical background, Propeller is very user friendly. I’d compare it to an Apple device. The routines and tools are very intuitive.

How do you use the Propeller Platform and/or drones in your role?

Before Propeller, I had to use two different programs in tandem to get the numbers I needed. With Propeller, I can get that same data more easily and usually much more quickly.

The thing that I really like about Propeller is the ability it provides me to share results with management teams in an interactive, three-dimensional environment. This has been much more helpful than earlier, two-dimensional models.

What’s one major way that one or both of these tools have changed your day-to-day work?

Propeller has significantly enhanced my ability to communicate the results of my work. I am the go-to person for employees’ mine planning questions. The ability to simply share my screen and talk through plans on a 3D model, where you can be much more specific about what you’re discussing, has been invaluable.

I cover a large division, with more than 60 actives sites in North and South Carolina, Virginia, and Maryland. I’m often at these sites, talking with the teams that manage them about how they plan to develop their sites. Having a tool like Propeller allows us to easily share plans and ideas and helps keep everyone on the same page.

When are your plans for expanding drone surveying and the Propeller use in 2019?

I’m excited to be working with Propeller to develop a division-wide drone program for Martin Marietta. We’re training regional pilots, who can share in the piloting responsibilities, and these new pilots could each fly approximately five sites per month. We envision flying approximately 30 times per month total—at the start.

When we first got Propeller, it was just me doing measurements and sharing them. But as we develop our drone program, we’re going to work with and educate our team members so they feel confident enough to go into the Platform and do the measurements themselves. From there, we can further expand our use of Propeller.

There aren’t many women in the industry, what advice would you give to those entering the field?

For those thinking about entering mining engineering, I’d encourage it. There are a lot of opportunities and room for growth. I see my role as mine planner for the division as constantly helping teams find solutions to the problems they face at their sites. It’s very gratifying work.

In the industry itself, a lot of experienced miners are preparing to retire. With the technology advancing as it is, there are many ways we can adapt to that technology and use it to optimize our operations. The drones are a perfect example of this.

How do you see the mining and aggregates industry changing in the next five years?

Comprehensive mine planning is critical to making informed business decisions. The tools available to mine planners and on-site teams continue to improve, helping us understand and overcome challenges before they become problems in the field.

The data we bring to the table as mine planners can help our sites operate more efficiently and help our managers make better decisions. It’s a much more proactive approach to doing business and one that is necessary if we are to succeed in a very competitive industry.

You might also like:

Quarry Manager’s Guide to Drones

Starting a Drone Program on Site: the Drone Regulations You Need to Know

Women in Construction Q&A: Alaska DOT’s Brandy Milles