What is Photogrammetry and How Is It Used for Worksite Surveying?

Photogrammetry is the science of collecting physical information from 2D photos, often aerial images captured by drones.

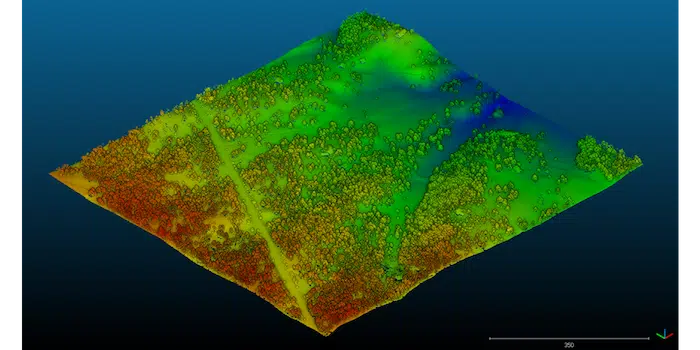

By combining enough overlapping images of the same features, photogrammetry software can be used to generate photorealistic 3D representations of topographic surfaces.

Surveying and GIS professionals use drone photogrammetry, along with accurate GPS data (usually from ground control points), to create 3D maps and models for use in construction, waste management, mining, and aggregates workflows.

You have likely heard the term photogrammetry before, but what is photogrammetry and why is it beneficial for your worksite surveys? In drone surveying, photogrammetry is the process of measuring real-world objects and terrain features from aerial imagery. As drones follow their programmed flight path, they collect thousands of photographs of conditions on the ground.

Although it may seem like the drone is collecting more images than you actually need during land surveying, the multiple target points of one location on the ground are processed to create a 2D orthophoto and a 3D digital terrain model that’s an exact representation of conditions on a worksite. These highly accurate 3D models are surprisingly useful for a wide range of industries, including civil construction, mining, aggregates, and waste management.

Photogrammetry applications in earthworks

Aerial photogrammetry is a quick, cost-effective method for collecting data at a variety of sites. In fact, there are certain situations where photogrammetry is the best option, namely civil construction/earthworks; mining and aggregates; and waste management. Since these industries rely on incredibly precise points, site managers rely on the realistic mapping results from photogrammetric data.

Some key industry-specific benefits include:

- Civil construction: Photogrammetry technology is invaluable for infrastructure planning and design. Real-time data helps construction workers manage site progress, keeping costs down and preventing delays.

- Earthworks: Photogrammetry creates topographic maps of earthworks sites. The data is key for identifying precise earthwork quantities. Not only does photogrammetry data provide verification of work, but it also helps keep projects running smoothly and within budget with volume measurements that accurately calculate costs and labor time.

- Mining and aggregates: The digital terrain models created with the help of photogrammetry helps mining operators obtain quick information regarding stockpile volumes or areas to be excavated. Operators have easy access to up-to-date calculation of stockpile volumes, not only improving consistency in inventory reports but also speedy validation of the amount of material moved by subcontractors.

- Waste management: Digital surface models help site managers optimize their landfills by monitoring capacity and providing an accurate density reading for specific cells. Photogrammetry data allows site managers to make strategic decisions about where teams should spend their time, where to build new cells, and many other important choices.

Automated workflows helps survey teams harness the power of photogrammetry

It’s clear that there are many useful applications for drone survey technology on construction sites, quarries, landfills, and more. However, the technological requirements of drone mapping have traditionally been a barrier to widespread adoption on worksites.

Automated workflows with the help of advanced technology solutions like Propeller PPK enable survey teams to bypass manual processing and analysis headaches and take advantage of photogrammetry technology to create accurate and reliable 3D maps of their worksites.

Even on large-scale sites like quarries or major civil construction projects, the mass of photos and data can be processed quickly, delivering high-quality topographic renderings that can be used by all stakeholders to inform project status and future decisions.

With Propeller, teams have access to an up-to-date view of real-world conditions on the ground, improving safety and sustainability on a worksite, and providing usable data that optimizes operations.