Five Ways to Use Drones and Propeller for Road Construction Surveying

Road projects may seem deceptively simple to the outsider, but more work goes into the surveying process for road construction than the average driver imagines. Accuracy is critical at every stage, from clearing the site to laying the first materials.

As drones have become the surveyor’s tool of choice on all kinds of worksites, it’s increasingly common to see drone surveys at work on paving jobs. But many paving contractors are still new to using drone technology to level up their operations.

It’s true that the level of accuracy achievable in drone surveying (1/10 foot) can’t consistently deliver the sub-centimeter accuracy required for the asphalt or cement layer of a finished surface. But if you think the story ends there, you’re selling drones—and your roadwork operations—short.

When paired with proper ground control or Propeller’s AeroPoints, drone photogrammetry is an ideal solution for the earthwork, subgrade, and subbase phases of road construction surveying. Drones can even help with staging, too.

Here are five ways drones and Propeller can help with your next roadwork project.

1. Measure earthwork and soil accurately

If you’re a road contractor, you already know that paving doesn’t just mean laying down asphalt or cement on the bare earth.

First, you clear the area by removing vegetation and other obstructions. Then, the road is shaped with a combination of motor graders and bulldozers. Treated dirt or soil form the base layer, and aggregate is laid over that base.

Each layer must match spec, and that’s where Propeller’s 3D survey data comes in.

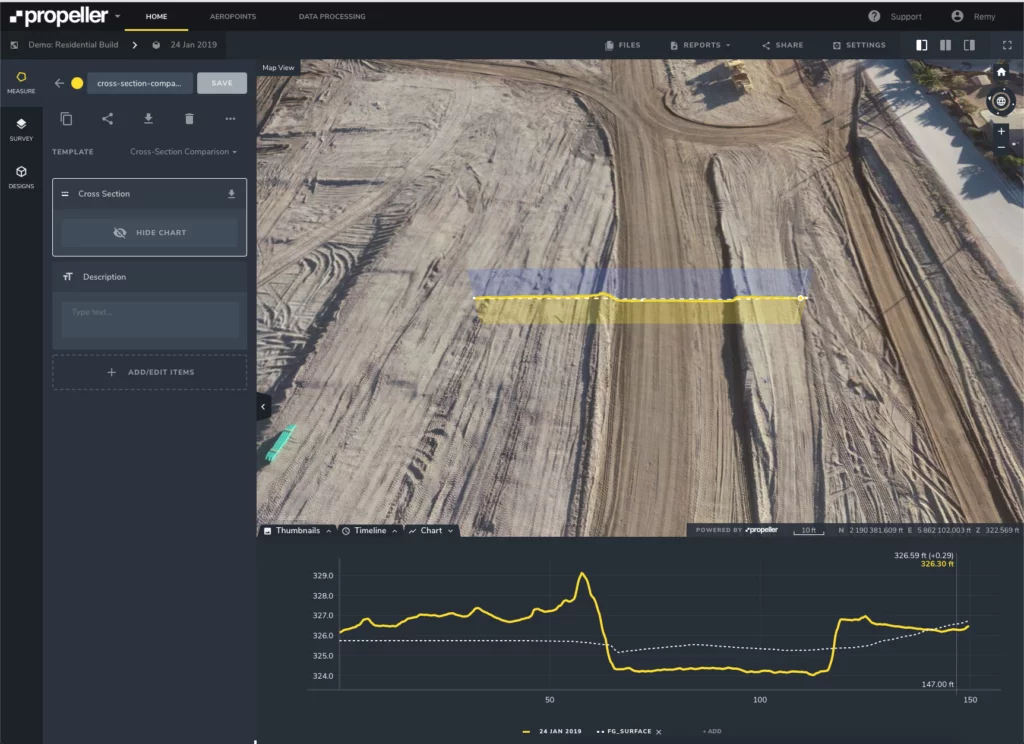

After completing your road survey with a workflow like Propeller PPK, your data will upload and process automatically. From there, it’s just a matter of drawing a line to measure a gradient or cross-section against the final design to see how far you have to go.

2. Measure subgrade and subbase

When it comes to the subgrade and subbase, drone surveying with Propeller allows you to capture and visualize your data. Measure your grades, and see them represented in a 3D model of your site.

As the subgrade, subbase, and base course are placed and compacted, you need a way to ensure those layers are on grade.

With Propeller, you can measure cross-sections and road grades in real time. Then, compare existing surfaces against design in a few clicks. Keep the whole crew on track, and spot mistakes before they cost you money.

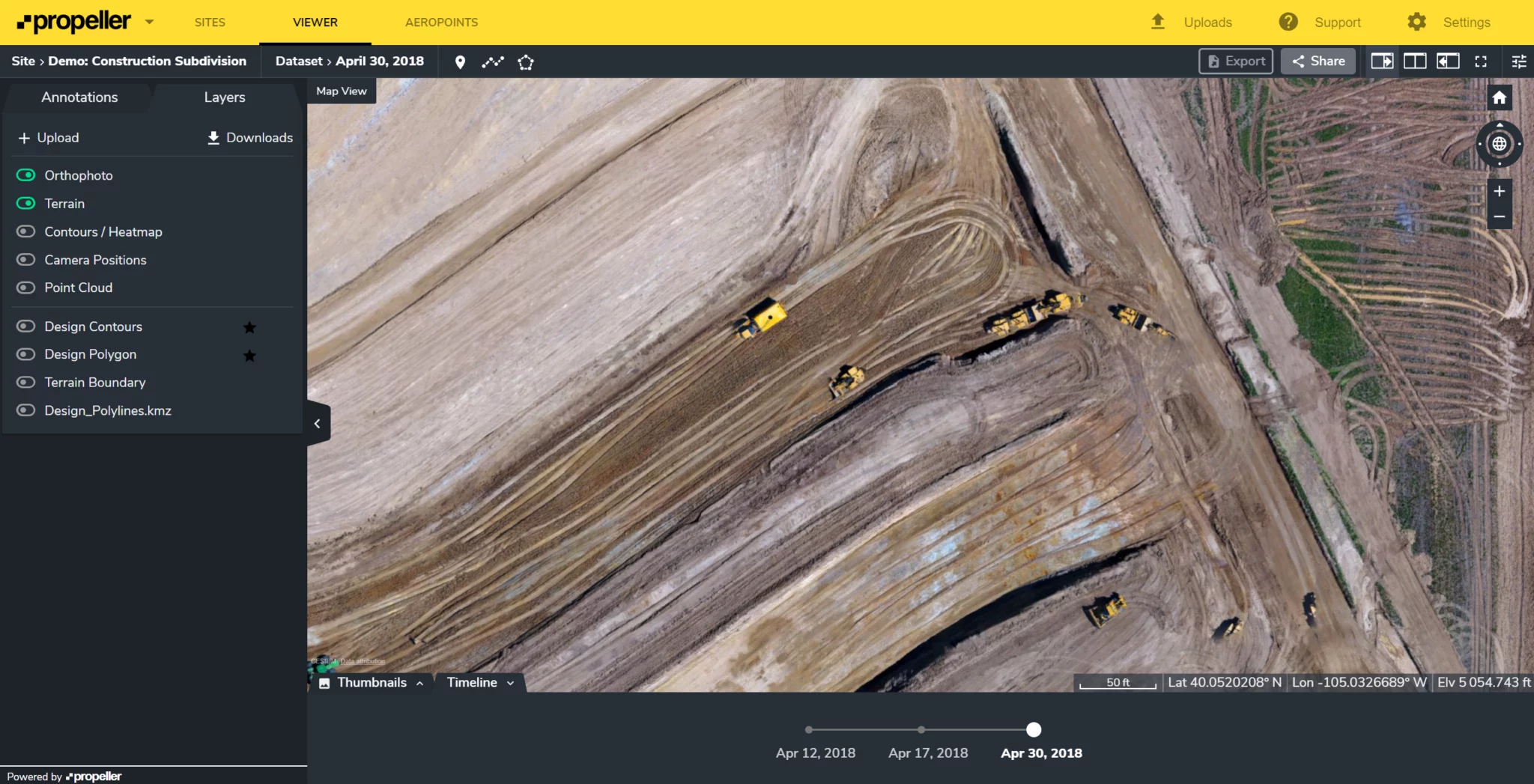

3. Track progress with a bird’s-eye view

Sure, the topmost layer of paving requires a level of accuracy that drone photogrammetry doesn’t achieve (yet)—but that doesn’t mean you can’t track your progress.

Capture images of roadwork as it progresses every time you fly the worksite. Then, use Propeller’s Timeline feature to see how quickly you’re progressing from a bird’s-eye view. Calculate whether your key milestones are on time or behind schedule, and use progress updates to reallocate crew, materials, and equipment as needed throughout the project.

4. Never lose sight of the big picture

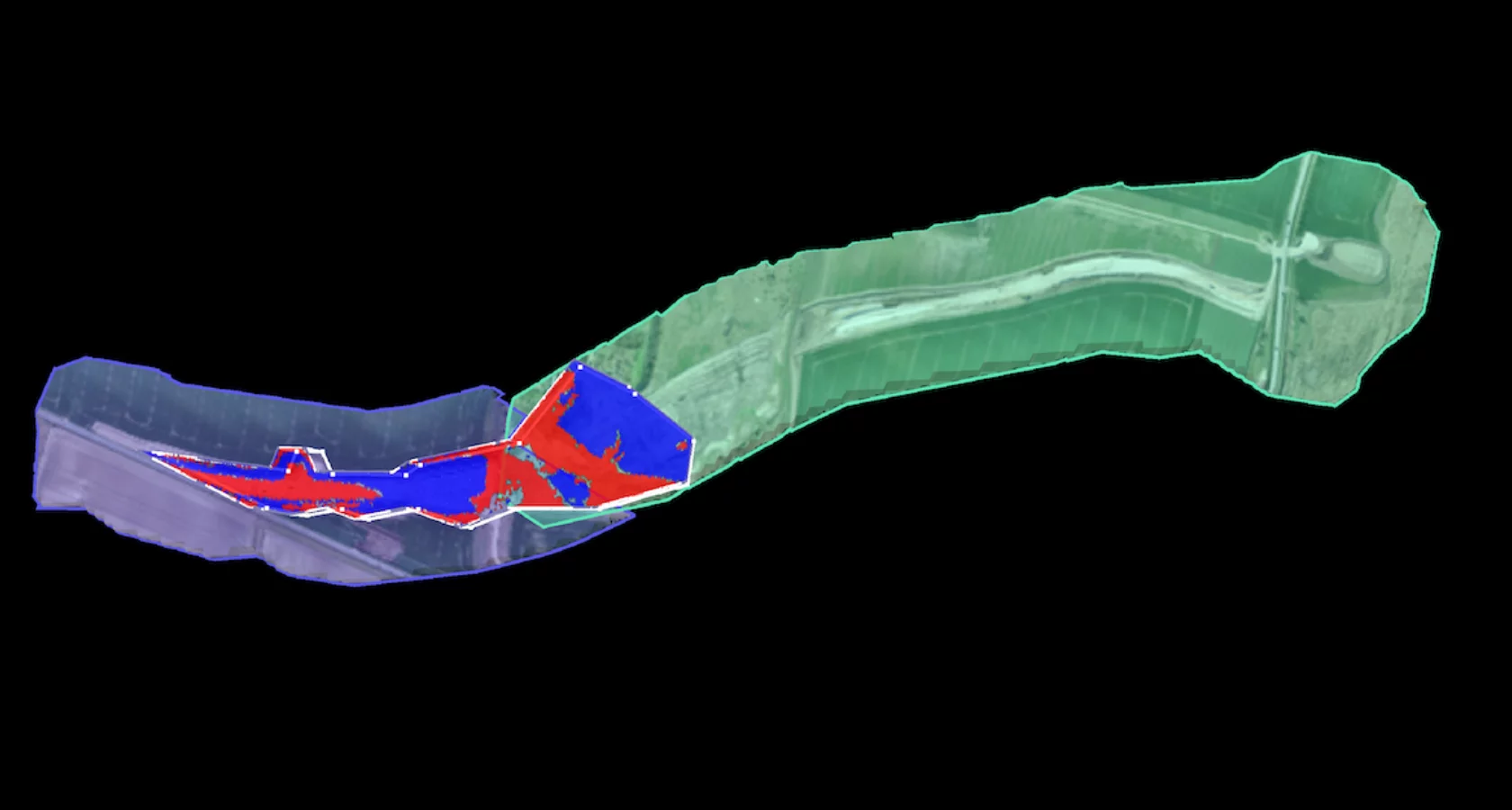

During the earthworks phase of any project, worksites can change by the hour. Surveyors, supervisors, project managers, and engineers need accurate data to prevent mistakes and make informed decisions about what comes next.

On large paving projects, getting access to up-to-date survey data is challenging, even with the latest drone technology. A survey of the entire site might take a whole week to complete, and you’ll waste time surveying inactive areas in the process of gathering a complete picture.

Propeller’s Composite Surveys allow for automated stitching of smaller surveys taken at different times, so you can combine new surveys of active sections with older ones to create a concrete, 3-dimensional whole.

Here’s what that means to you: survey managers and engineers on even the largest worksites now have quick, easy access to reliable data.

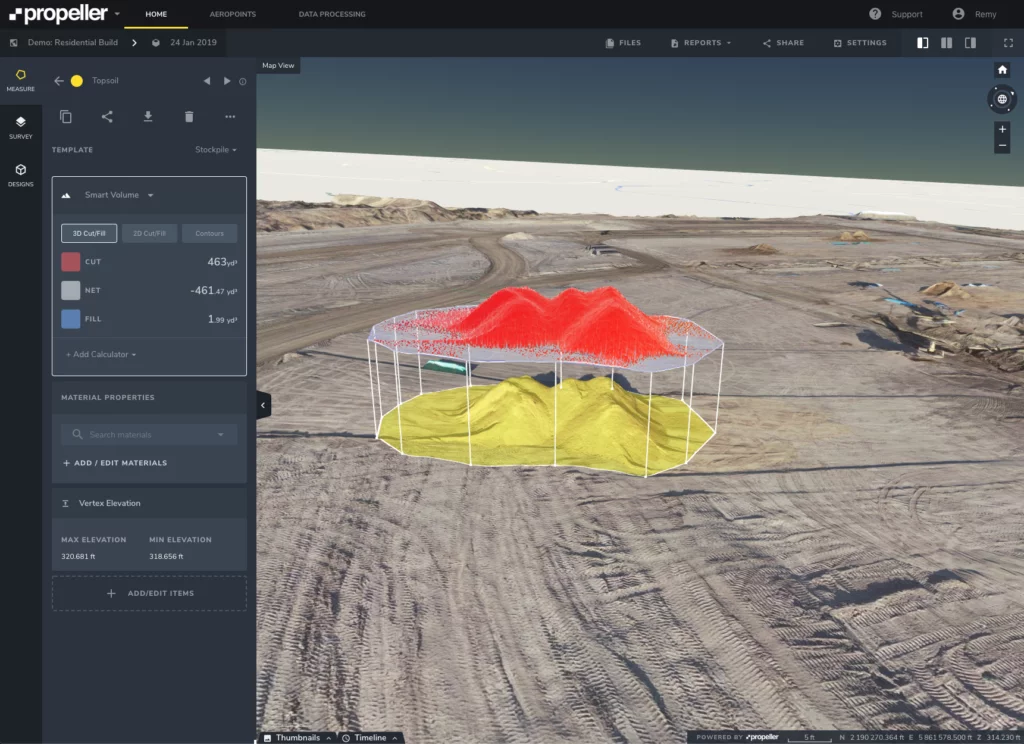

5. Ensure efficient material staging

The bird’s-eye view you get with drone photogrammetry helps you stage material in set intervals, so you don’t have to move it twice.

You can also use the Platform to measure temporary stockpiles. Imagine never having to guess how much material you have on-site, or where that material is—just the rock-solid info your team needs to keep working.

If you have a stockyard and recycle blacktop, you can also use drones to survey the stockpiles and measure them in the same way.

Drones are changing the landscape of road construction surveying

On a roadwork project, Propeller’s PPK workflow improves efficiency and safety, ensures accurate grades and cross-sections, streamlines material allocation, and allows you to track progress against design using a 3D model.

That’s a positive impact on about three-quarters of the average paving operation, particularly a new road build or tracking net new road.

Spot problems before they get expensive, hit your grades, and improve overall efficiency—powered by Propeller.

Learn more about how drone surveying and 3D mapping can change your business. Contact us today.