Use The Ultimate Guide to PPK Drone Surveying

It’s been almost two years since DJI released its Phantom 4 RTK drone to great fanfare. This drone laid the foundation for Propeller’s PPK drone surveying workflow–a reliable, accurate solution used to collect survey data on all types of worksites.

To help you understand the power that our post-processing offers, we’ve put together a FREE Beginner’s Guide to PPK Drone Surveying ebook. You can download the ebook by clicking the link below, or continue scrolling for a brief rundown of PPK drone surveying fundamentals.

How it works: PPK vs. traditional drone surveying

Post-processing kinematic (PPK) workflows are more accessible than ever. But there’s still much confusion about what the technology is, how it works, and what’s best for your surveying needs.

To cut through the complexity, let’s briefly explain how PPK workflows differ from GCP-based (traditional) drone surveying and how RTK technology plays into it all. (Check out our full blog on PPK vs. GCP workflows for more information.)

The place of ground control in traditional drone surveying

For our purposes, we’ll define “traditional drone surveying” as drone surveying carried out with a standard drone that doesn’t possess GPS correctional capabilities. Essentially, they’re just a vehicle for the camera.

In this case, a number of known points are needed to pin drone imagery to the ground. The drone’s position in the sky is not accurately geotagged, so you don’t get reliable positional data from its hardware alone.

That’s where ground control comes in. It’s also why even small errors in ground control setup can have huge repercussions.

Ground control points (GCPs) can be known points marked and measured with base and rover or a moveable smart ground control points like Propeller’s AeroPoints.

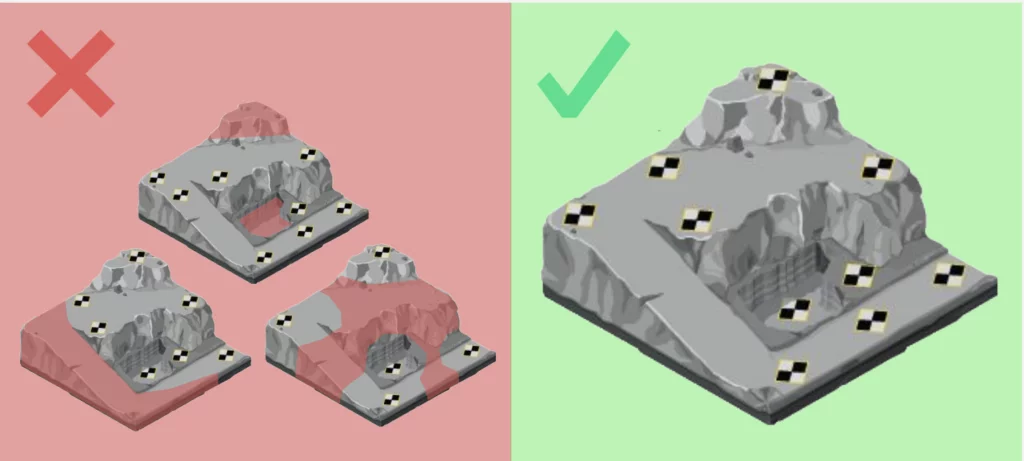

Using GCPs when surveying increases accuracy, but the setup can be time-consuming on a large site.

Setting up ground control with AeroPoints

Hardware should be placed in an optimal distribution across the entire surveyed area. (This method also takes time, but it saves on shooting points with a rover on foot and painting them for visibility.) Once AeroPoints are in place, you can activate them with a single button.

Now that we get how traditional drone surveying works, we have a basis to understand how PPK technology improves on it. But before we can explore the PPK workflow itself, you need to understand the RTK technology that powers it.

How onboard RTK technology works

Recall that the name of DJI’s drone is the “Phantom 4 RTK.” So what does it have to do with PPK? It’s not an apples-to-apples comparison. The PPK workflow leverages RTK data as a piece of the processing puzzle.

The difference with PPK workflows is how base station data is processed for correction and accuracy. (We’ll be exploring the workflow of Propeller’s PPK solution here.)

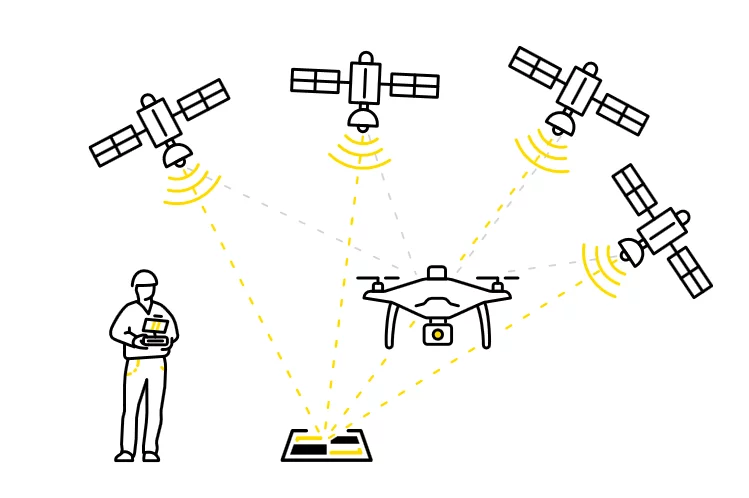

RTK hardware is important during your flight. It records GPS information and geotags images as they’re captured during flight.

A base station is also needed on the ground to transmit raw GPS data to the drone. (For Propeller PPK, an AeroPoint is used.) The drone’s onboard GPS then combines that info and its own observations to accurately determine its position relative to the base.

PPK comes in when the flight’s concluded. After data upload, the two sets of GPS data from the drone and base station are matched up using the photo timestamps. Then, the initial, less-than-accurate onboard GPS data is corrected, giving precise geotags for the imagery.

What does drone surveying with Propeller PPK look like in practice?

The operational workflow couldn’t get any simpler:

- Plan out your drone’s flight on the flight planning app

- Find a safe, open area on your site to launch the drone from

- Set up an AeroPoint on the ground nearby you and turn it on

- Hit Go on your drone flight

Once the drone finishes its flight and automatically returns to your location, you upload your survey data to Propeller and we process it for you. No need to download any software. No need to tweak or preprocess imagery or site data. And we’ll get your data back in 24 hours.

How Propeller PPK can change your surveying workflows for the better

Every worksite is coming to this technology from a different place. We thought it would be useful to outline how PPK surveying changes existing workflows.

Most everyone is coming from one of two camps: (1) you don’t use drones for surveying at all, or (2) you do GCP-based drone surveying.

Let’s start with the former.

How Propeller PPK revolutionizes drone surveying if you haven’t used drones before

Drone surveying reduces your end-to-end surveying time from days or weeks to hours. This means you can survey more often and get the data you need about your site.

UAVs don’t require advanced personnel training or education, so you can capture data yourself. (Note: you do need a license to operate a drone commercially. In the US, it’s a Part 107, which is relatively easy to get.)

Instead of sending out personnel to trek over your site with base and rover, you can take one AeroPoint and your drone and fly your site in a few minutes to a few hours, depending on site size.

It is important to understand, however, that the drone isn’t a replacement for the base and rover. Rather, it’s another tool in the surveyor’s toolbox. Think of it this way: the capabilities of a drone complement those of a base and rover. They’re both a part of the surveying equation.

How Propeller PPK improves GCP-based drone surveying

The benefits you get from Propeller PPK differ a bit when you’re starting out already surveying by drone. It all comes down to two things: time-savings and greater accuracy.

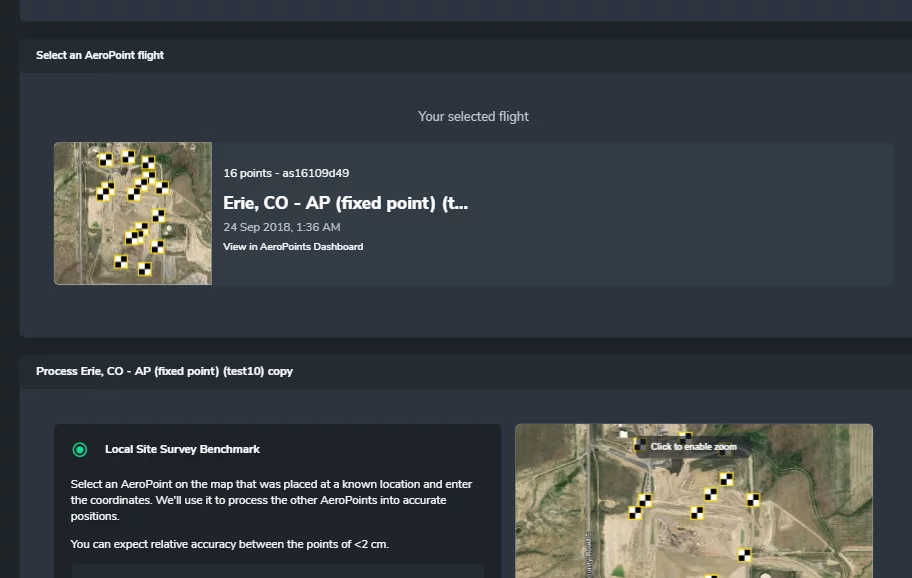

It’s hard not to overstate, but all the ground control you need to set up is an AeroPoint near your takeoff location. (If you’re working in a local grid, that GCP needs to be on a known point.)

You still need to map out your drone’s flight route, of course, but there’s no need to hike all over your site to lay out ground control. More AeroPoints can serve as checkpoints and additional validation.

After that, no matter where you started out in the two above scenarios, the next step is completing your flight and uploading data to Propeller. We process your geotags and images in 24 hours. The accuracy is down to 1/10ft or less—that’s the survey-grade industry standard.

Now, you might be skeptical. How can we really get it down to a 10th of a foot? The answer is good tools, a tried-and-tested workflow, and post-processing.

How you actually get drone data accuracy down to 1/10th of a foot

“Our mission at Propeller has always been accuracy,” said Propeller Co-founder and CEO Rory San Miguel. “First it was making ground control easy with AeroPoints, and now the next big accuracy push is PPK.” We chose PPK because it’s a fundamentally easier way of capturing and collecting data.

Getting Propeller PPK’s accuracy down to 1/10ft was a process of continuous improvement, as most projects are in hardware and software development.

Testing the Propeller PPK drone solution in the wild

After we had the backend processes down pat, we tested the workflow in the field.

Beginning in March 2018, we took DJI’s Phantom 4 RTK drone and an AeroPoint to numerous sites in the US and Australia. Each time, we crunched the numbers and refined the workflow.

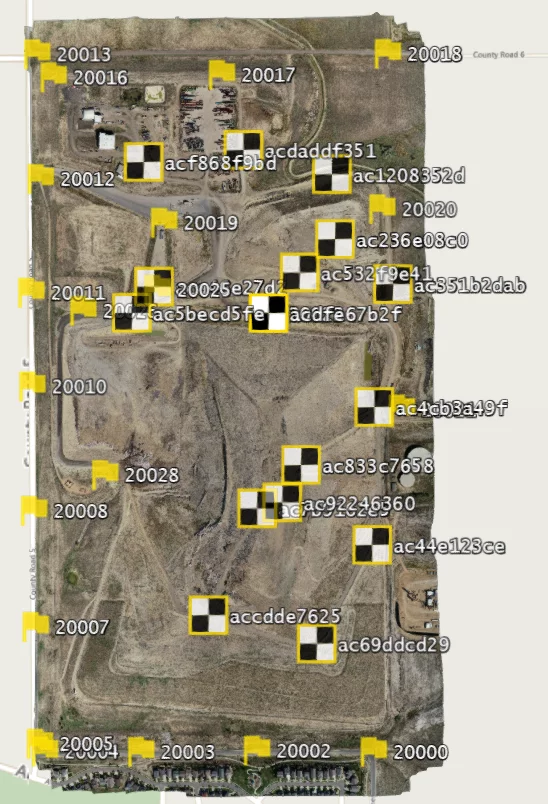

Following success in many, many unpublished flights on real-world sites, we did an official accuracy test at Front Range Landfill in Erie, Colorado, an hour north of Propeller’s Denver office.

“The thing we were trying to test is how well the data agrees with conventional methods of surveying,” said Fred Greer, our lead AeroPoints engineer.

A team of Propeller engineers and drone surveying experts tested Propeller PPK’s accuracy against checkpoints on site and against a site survey rendered with lots of ground control and a traditional drone.

Real-world testing and 1/10ft accuracy

“The first thing we did was set lots and lots of control points, both using the AeroPoints but also using Trimble’s survey equipment,” said Greer.

“From that, we had a big list of known points that we knew very accurately on site. So, we flew the drone and we processed all of the test data using our conventional workflow, ignoring any PPK or RTK data—just using the images and the ground control data—and making what we’re confident is a good drone survey.”

That first test flight had accuracy of 1/10ft (3cm) or under.

“We flew the site a week later and processed the data using the exact same method [to] prove repeatability and reliability of this accuracy,” said Greer. “When the team did the same survey a second time, we incorporated the RTK/PPK data using only one of those control points and comparing it to the first drone survey and all the checkpoints around the site.”

The results of the second flight were, again, accuracy of 1/10ft (3cm) or under.

These tests proved the Propeller PPK workflow gives survey-grade accuracy reliably. Further testing in the real world allowed us to refine the steps of the workflow itself.

[Read more about our testing methods and process in our whitepaper Propeller PPK Solution: How Accurate Is It]

A quick recap: Why PPK is the workflow for you

We get it—“post-processing kinematics” seems like a lot to take on, but it’s a means to a greater end (we promise).

The earthwork industry is quickly evolving, coming to the understanding that a combination of technology and manpower enables a more balanced worksite. And, after the initial drone disruption, some really smart people got to work trying to perfect the formula for accurate aerial data.

What they found is that two datasets is always better than one. If we weigh what’s happening in the sky against what’s happening on the ground, we get significantly closer to each image’s real-world location. Thus, PPK was born.

So, what does the PPK workflow get you? It gets you powerful analysis into the inner workings of your site—how far you’ve come, resource expenditure, stockpile movement—without absorbing a ton of your time (especially with ground control setup).

A short learning curve is a small price to pay for a safer, more efficient, more connected worksite. At least, that’s what our customers tell us. Want to read what customers in your industry have to say about Propeller PPK on their sites?

See how people are using Propeller PPK in real life in these case studies:

- Sukut Is Using Propeller to Save Time, Money on California Dam Project

- Kentucky-based Haydon Materials Uses Propeller for Quarry End-of-Month and More

- Blount Contracting Saves Processing Time, Easily Creates Machine Surfaces in Arizona

- California Landfill Calculates Remaining Airspace, Tracks Compaction with Propeller

You might also like:

Kansas-based Hamm Companies Saves Surveying and Data Processing Time with Propeller