The Benefits of 3D Modeling throughout the Construction Project Lifecycle

In the construction industry, it’s critical that projects stay precise, timely, and safe. While that may sound relatively simple—after all, what industry doesn’t value those things?—the construction process is especially complex, with many moving parts. That’s why the benefits of 3D modeling in construction are so numerous.

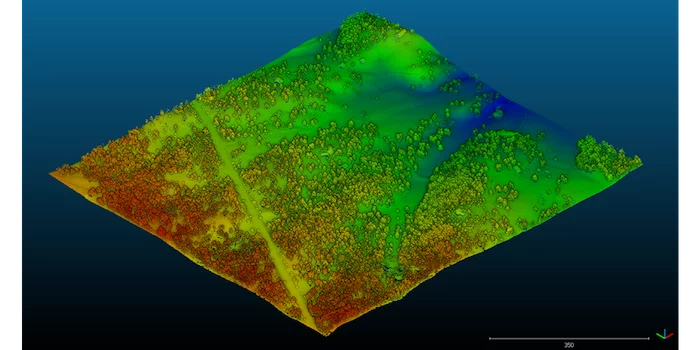

Modern technology like 3D modeling from drone surveys is literally changing the landscape of the construction industry. At every stage of a project lifecycle, from takeoff to construction and beyond, 3D modeling software can keep construction projects on track and on budget.

An accurate 3D model is essential to reaping these benefits, but there’s good news—accuracy isn’t difficult to achieve once you understand the basics. Here’s how 3D modeling can help at every stage in a project lifecycle.

Before construction

At the beginning of a project, 3D modeling enables teams to simulate potential designs, estimate unnecessary costs, and identify flaws within architectural models.

Accurate 3D models of the surrounding landscape help to:

- Calculate costs related to ground leveling, foundation pouring, and other preparation work

- Simulate weather effects, such as the potential for flooding

- Estimate a project’s impact on the surrounding neighborhood and terrain

An excellent 3D model begins with the terrain and is built up using a combination of real-world images and computerized simulations until it is a near-perfect match of the proposed project. All principal stakeholders can then access this 3D model to review potential changes and stay on the same page.

In the past, it was difficult for people to grasp how a worksite would look when the project was complete. Using 3D modeling, engineers, survey managers, and project managers can walk through a virtual project model before it’s even been built. These models go far beyond simple aesthetics. Accurate 3D modeling of construction projects helps in forecasting project costs, as it’s easier to get precise measurements of the materials and labor required.

Unlike reality, 3D models allow for the swapping of materials and engineering solutions multiple times during planning, to reduce project costs without compromising safety or stability. The higher the accuracy during the initial stages of the project, the less likely the project will require rework, which can cost a company millions of dollars, and they’re usually caused by errors in the initial data.

As 3D modeling becomes more advanced and the data collected becomes more extensive, the construction project rework is reduced significantly.

During construction

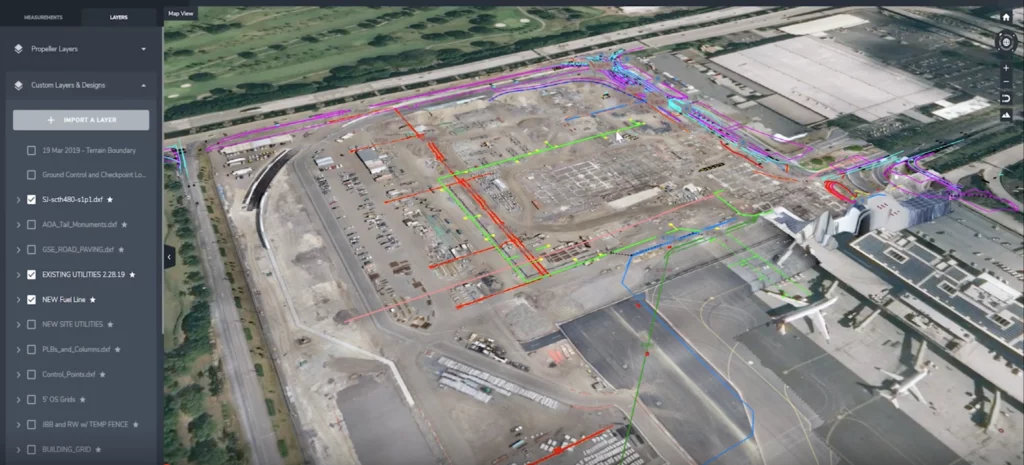

During construction, 3D models are used to ensure that projects stay on track and on time. You can easily make comparisons between the current state of your worksite and any pre-work survey. You can also overlay linework to compare your site surface to the projected surface, to ensure the site looks as it should compared to plan.

Using drones, contractors can survey a construction site in as little as two minutes of flight time. Then, with automated data processing, you can automatically compare current scans with 3D models of the projected completion. If recent surveys don’t match your projected models as they should, you can review any changes and make modifications as needed, before the project gets too far off track.

Learn how drones saved one Propeller customer 10x their investment

Drones complete detailed site scans via lidar or photogrammetry and combine them with location data from an onboard GPS, allowing them to digitally recreate a site surface with accuracy up to 1/10 foot.

There are numerous advantages to completing these surveys from the air rather than on foot. Drones can cover even large construction sites very quickly, report data back almost immediately, and don’t interfere with ongoing work. They are also perfect for safety checks on an active construction site; they’re not invasive or disruptive, and an aerial view means workers remain safe.

Because 3D site models are so easy to view and understand, the data is easy to share. 3D modeling helps provide reports to external stakeholders like clients or subcontractors, demonstrating that work is on target for any relevant deadlines and letting them see the in-progress worksite without requiring a visit.

And having a highly-accurate 3D simulation of your site improves your ability to hit project deadlines, since any issues that could create delays can be caught and fixed early.

After construction

Once a project is complete, a site’s 3D models can be archived for use later. They will come in handy any time the construction project needs to be modified, retrofitted, updated, or extended. Through cloud-based data services, you can keep everything you might need to reference again without taking up space on your servers, and you can access it from anywhere in the world.

New additions can be inserted directly into 3D models to simulate how they would impact the overall project before any dirt is moved. It’s a virtual test run that can save thousands of dollars.

Accurate 3D modeling allows your data to live on and remain accessible for future use. Architects, engineers, and subcontractors can review as many scenarios as they need regarding potential changes in the project before they take action, and information about the surrounding terrain and improvements remain accessible.

Key takeaways

3D modeling is already being used extensively to aid construction projects. Accurate 3D modeling makes it possible for you to look both backward and forward in time, seeing exactly how a project has progressed, how the current state compares to plan, and when it will be complete. You can even measure its likely impact on the surrounding area.

Read about how 3D modeling from drones is making mining reclamation easier

Modeled projects achieve lower cost, better lead times, and greater safety and stability—and it’s all done through drone technology.

Drones make it possible to take high-resolution, complex scans of a terrain—and because they’re so easy to use, you can do this throughout an ongoing project. Using drone technology, our customers reduce their costs while improving their consistency.