Spotlight on DirtMate: How Does it Work?

DirtMate is an easy-to-use, cost effective machine tracking system that provides teams with easy access to critical productivity insights every day.

Critical site data is often gathered infrequently and pulled from many (often disconnected) sources, leading to data gaps that impair your ability to effectively manage your project. DirtMate helps fill in those data gaps, giving you a complete and highly accurate view into how production is tracking at the end of every day.

Let’s dig a little deeper into the nitty gritty of how DirtMate works.

Machine-mounted device

DirtMates are solar-powered and can be installed on any moving vehicle or equipment on site with a simple magnetic mount or easy-to-install bracket. This means there’s no need to drill, wire, or weld the system in place, keeping downtime and complexity to a minimum. In fact, most installations only take 15 minutes to install and calibrate DirtMates. And, because DirtMate is independent of any specific manufacturer, contractors can use it on any and all machines on site.

When DirtMates are installed on working machines, they can record position and utilization data that represents the specific machine they are mounted on, every second.

Daily volumes and operations data

DirtMate is a survey-grade machine sensor that provides daily volumes and production efficiency data. It uses a built-in GPS receiver to not only track machine movement on site, but also continuously collect elevation data from any surface the machine drives over with PPK accuracy.

The onboard inertial measurement unit (IMU) contains a gyroscope, accelerometer and magnetometer to track vibrations and determine if a machine is working, turned off, or sitting idle on site so you can better optimize your fleet.

Plus, you can gain automated insights, delivered daily to your email inbox. Each email provides a summary from DirtMate, highlighting if production and utilization is trending up or down. This means you can proactively identify and solve issues before they escalate. And, because these summaries are delivered via email every day, you don’t need to worry about remembering to log in. DirtMate makes those insights simple to get and manage.

DirtMate survey data

When in range, DirtMates connect wirelessly to the Propeller Network Gateway and stream data back to the Propeller Platform for storage. The data is post-processed using the Propeller PPK engine to produce a centimeter-accuracy trail of coordinates. Data from the base DirtMate on the work site is used as the reference receiver, in the same manner as the base GNSS receiver is used in a traditional base and rover setup.

Each GPS coordinate is then combined with the dimensions of the machine (height, track or wheel width and DirtMate offset) to determine the position of the blade or wheels touching the ground. But before each coordinate point is included in the surface calculation, it’s checked for GNSS processing quality, and Propeller confirms the machine velocity and acceleration is accurate.

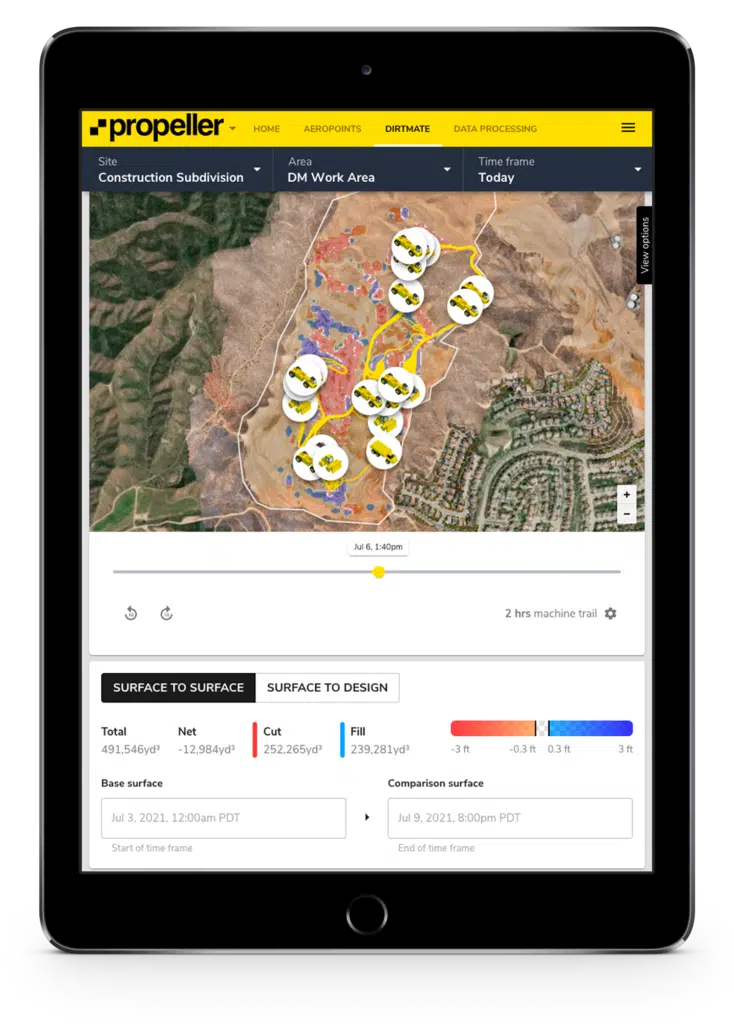

Then, once processed, DirtMate layer updates are pushed to the DirtMate Dashboard in Propeller every 30 minutes. Positional data, including machine tracks are overlaid on the most recent drone survey surface map to show machine movement and locations and allow for up-to-date cut and fill volume measurements. When a new drone survey is uploaded, the surface is “reset” and only DirtMate data after this survey is used for later volume measurements.

Check points measured on static areas of the site (e.g. roadways) can also be used. Whenever a machine drives over one of these points, the DirtMate-derived elevation is compared to the check point elevation to confirm accuracy of the machine dimensions and GNSS coordinate quality.

DirtMate’s own 4G site system enables plug-and-play communication between the DirtMate and the processing engine. This supports published coordinate systems and local site calibrations, for seamless integration with your latest drone surveyed surface data.

What you get is a complete, updated, 3D map of your site that you can use to generate daily production volumes, cut and fill heatmaps, and progress-to-design measurements within the Propeller Platform.

DirtMate tablet-friendly dashboard

The DirtMate Dashboard, designed specifically for use in the field, offers a lightweight and easily customizable view of productivity and machine utilization data—giving anyone on site the power to see what’s happening and take corrective action as needed.

DirtMate Dashboard allows for custom views of specific areas, time frames, and data to deliver clear insights into the productivity and utilization of your DirtMate-equipped machines.

For example, with the DirtMate Dashboard, you will have access to:

- Accurate cut/fill volumes, charts, and heatmaps

- Automated truck load counts

- Consolidated (mixed fleet) utilization visible side-by-side with production data

- Haul route monitoring

- Subcontractor performance visibility

- High accuracy (5cm) surface data

- And more

This level of visibility puts you at the center of your project with views into the data and metrics that matter most.

Is DirtMate right for your earthworks operation?

Today, drone surveying is used to create survey-grade site maps and calculate volumes moved.

DirtMate harnesses the power of high-accuracy drone surveying and combines it with the convenience of machine tracking data to deliver production quantities with survey-grade accuracy, daily.

So, realistically, if you move dirt on a worksite and want more visibility into your team’s progress, material volumes, and more, it’s a simple solution – DirtMate and Propeller.

DirtMate + Drone Surveying + Propeller = Next Generation of Worksite Progress Tracking

For more details about DirtMate, grab some time with one of our representatives.