Six Smart Ways Mines and Quarries are Using Drones

The mines and quarries are highly exposed to fluctuations in price and demand. As a result, these businesses are always on the lookout for new ways to increase productivity while maintaining safety standards and reducing operational costs.

In 2017, drones have emerged as a must-have worksite tool. Regular drone surveys provide up-to-date information to site managers, project stakeholders, and contractors, helping open-cut mines and quarries all over the world better manage their production, assets, and land.

Here are some of the smartest ways these industries are putting drone technology to work:

1. Stockpile management and reporting

Stockpile management is perhaps the most widely used worksite application for drones, and for good reason: drones have completely transformed this common workflow. The days of “walking a stockpile” (the traditional approach whereby a surveyor takes measurements of numerous points on the each pile in order to calculate stock volumes within a spreadsheet) are surely numbered.

Using a drone, any trained site worker can now capture the entire sales yard in less than 30 minutes and see the processed dataset available on Propeller’s cloud platform within 24 hours. Within the platform, accurate volume calculations and comparisons can be generated in seconds, with all measurements easily exported to CSV files.

The ease of surveying stockpiles with a drone means site teams can capture data much more frequently, improving run-of-mine management and ensuring more consistent grades through the mill. At the same time, drones remove the risks that come with having survey personnel physically moving around the worksite.

In short, stockpile management alone can amount to an effective business case for introducing drones to any mining or aggregates worksite.

2. Planning and building

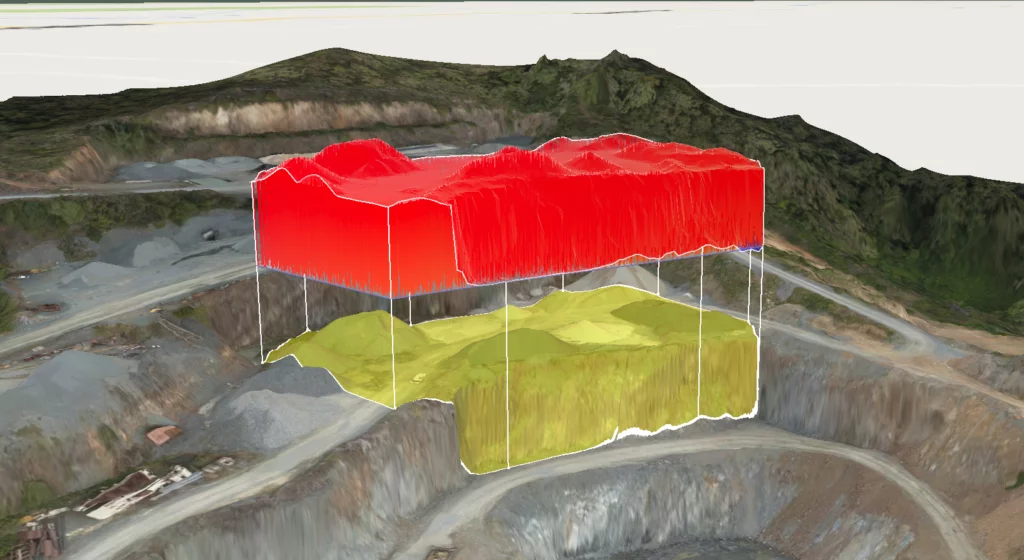

Drone data provides an accurate and up-to-date visualization of worksites allowing for better pit and dump design and management. With regular flights, sites can build up a visual record of changes over time, allowing site managers to check weekly/monthly pit volumes and compare the current surface against previous datasets.

By overlaying KLM design files on a 3D model within the Propeller platform, teams can check conformance of the actual surface and determine the exact volume of material that needs to be extracted to meet the design. Modeling sediment flow on drone-captured elevation maps also allows for better planning of tailings basin operations.

3. Drilling and blasting

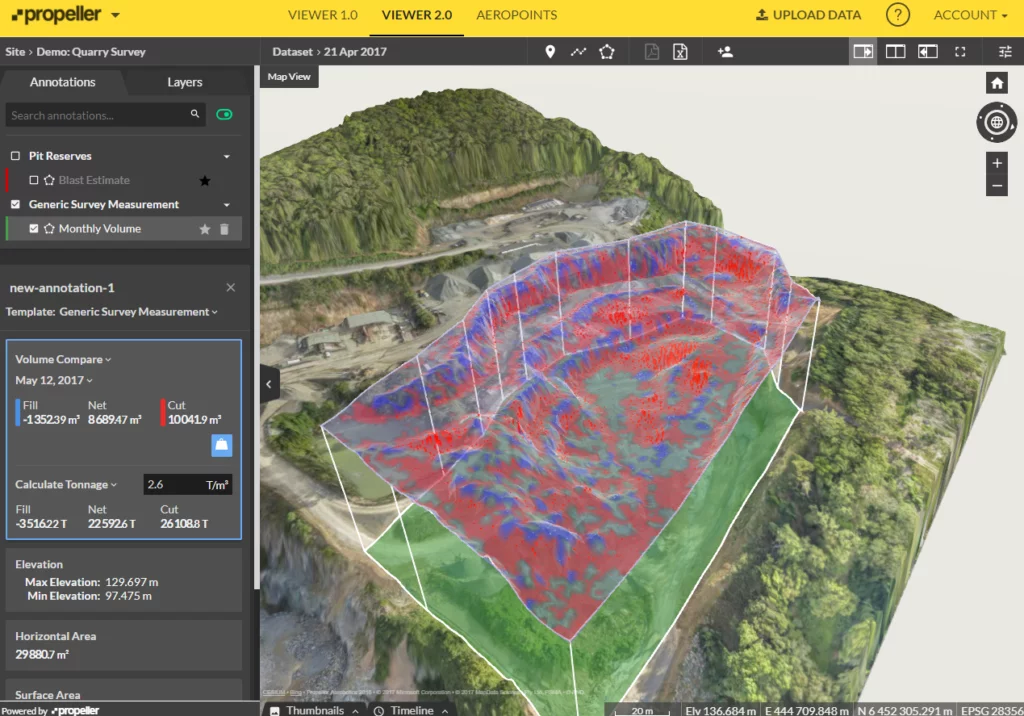

Regular drone flights are the best source of timely, reliable information for site managers responsible for planning and executing blasting work in an open pit mine or quarry.

Any blast area can be easily and inexpensively surveyed with a drone. The Propeller Platform processes the raw data, and presents it as accurate 3D models, orthophotos, and digital point clouds, allowing for easy drill depth calculations and further analysis.

The information that can be obtained from a preblast drone survey includes rock type variation in a bench, face angle, preblast block condition, and preblast volumes.

Postblast surveying provides data for measuring postblast volume, and visual assessment of blast results such as muckpile shape, back damage, and distribution and fragmentation.

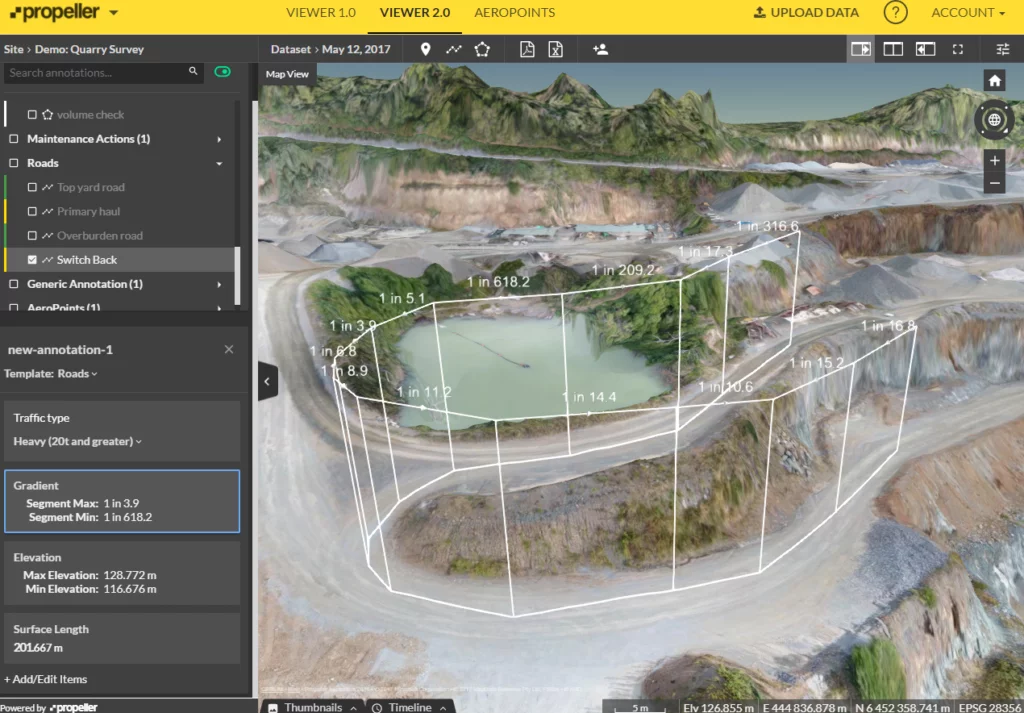

4. Roads monitoring

Drone data makes it easy to assess haul road conditions on a regular basis, and allows for accurate traffic planning. Advanced analytics options available within Propeller enable site personnel to calculate haul road lengths, measure slopes, grades, and check roads against design and safety requirements with a few clicks.

Using drone data to improve road and traffic management results in increased mobile plant efficiency and reduced cycle times.

5. Inspections

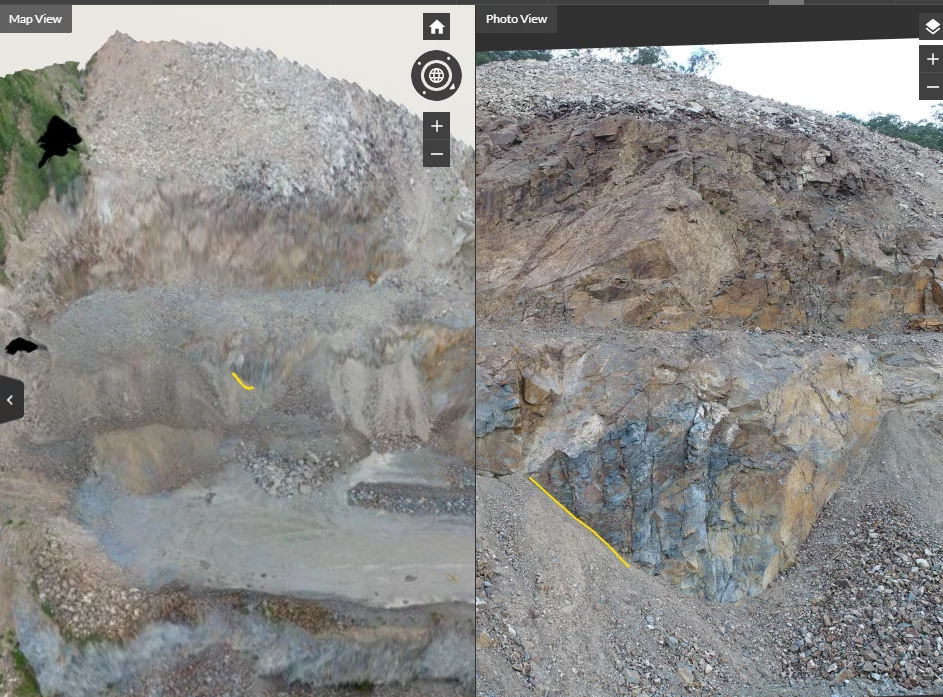

Drones are the perfect tool to quickly and inexpensively inspect hard-to-access areas. High-resolution images, including details and aspects that may not be visible from the ground, are used by multiple departments in a variety of inspection workflows.

Propeller’s timeline feature helps environmental departments ensure that site boundaries are preserved and protected areas are not disturbed.

Propeller’s Photo Pane view helps geologists perform accurate geotech mapping and rock face inspections, and assists in the close monitoring of fixed plant.

By being able to access data from various locations, all centrally and securely stored within the cloud, allows specialist teams to manage and service more sites than previously possible.

6. Safety checks

Everyone who works in mining and aggregates knows how important worksite safety is.

Using drones to perform remote surveys and inspections reduces risks to personnel by keeping them away from potentially hazardous locations like the bottom of the pit, block caves, and heavy traffic areas.

In addition, drone data helps teams better detect and monitor worksite hazards, improving overall site safety. Using Propeller, teams can easily check windrow heights, berms and tailings dams, and measure overall pit slope and individual slope angles to ensure compliance with safety requirements.

By comparing multiple datasets, site managers can monitor movement of highwalls, and identify potential slips or rock falls before they happen, preventing damage to people and equipment.