Quarry Manager’s Guide to Drones

In the last few years, drones have become an affordable tool for worksites. Unlike traditional surveyor equipment, you don’t need tons of special training and education to use it.

A successful drone program can provide your quarry with accurate, up-to-date information on progress and productivity, and information you can use to ensure high-quality work and minimize operational risks and costs.

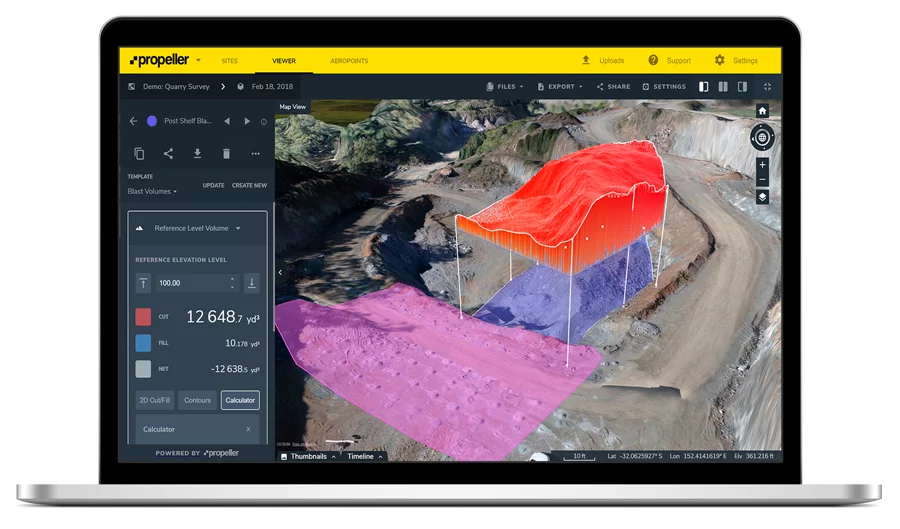

But collecting and processing your data is only half the story. Web-based platforms act as translators, making raw data readable. Take our own: it transforms drone-captured images into a fully navigable, fully measureable 3D survey of your quarry.

Check aviation regulations

Drones regulations differ depending on where you are. Do your research. What kind of airspace is your quarry located in? Is it restricted in some way? Do you need a special license?

Usually, all unmanned aerial vehicles (UAVs) are overseen by the country’s transportation administration, so check out your country’s website. (Websites and apps like Global Drone Regulations Database or B4YouFly are also helpful.)

What’s the optimal hardware for your quarry?

There are tons of drones to choose from, but to pick the one that’s right for your needs you should consider a few factors. How big is your survey area? What’s your budget? What about the type of camera?

Let’s begin with the types of drone: fixed-wing or multicopter? If your area is less than 200 hectares (500 acres), it can be done comfortably with a multicopter. Consider either more than one multicopter or a fixed-wing UAV for anything bigger.

Budget

Multicopters (especially those made by DJI) are mass produced and can be purchased easily and cheaply. Fixed-wing UAVs are still made in limited quantities, meaning units are significantly more expensive—sometimes up to a hundred times more pricey.

Availability and ease of maintenance

Along with sticker price, you want to keep in mind the added cost of maintenance and the availability of parts and replacements. It’s best to stick with simple options that are available at local stores. As with any other worksite tool, it’s best to avoid providers who cannot guarantee quick repairs or replacements. You don’t want to postpone your surveys because you’re waiting on a replacement drone or part.

Camera

Ensure your camera is high-resolution, with a large sensor and a 35mm-equivalent focal length. This lets you get more detail about points and increases image contrast, which helps generate better 3D renderings and point clouds. Keep in mind, too, specifications affecting ground sample distance (GSD) and resolution.

The GSD is the real-world size of a pixel in your images, which sets a physical limit on the accuracy of your aerial survey. (Flight altitude also affects this number.) If you want to fiddle with possible GSDs, we built this handy calculator to compute them. If you want more info, check out our article on what makes a good camera for drone surveys and inspections.

DJI Phantom 4 Pro is ideal for most quarries

With the exception of some edge cases related to size, DJI’s Phantom 4 Pro is an ideal craft for the majority of worksite survey applications. But the drone itself is just a starting point, a tool serving a greater use. To learn more, check out our blog on the topic.

Pick the right software for your quarry’s needs

As we’ve seen, there are various options for the hardware side of things, but you can usually rig together some combination to acquire the data you need. Software, however, is a different matter. It’s not an interchangeable tool. As quarry managers know, aggregates operations are complex, involving many levels of oversight, design, and management. You need to pick the software that’s right for your workflows.

There are a couple of software pieces that go into successful drone surveying. Let’s start with actually flying your drone.

Flight planning apps

The best way to achieve consistent, steady flight is with a flight planning app. After extensive field testing, we recommend DJI’s Ground Station Pro. The in-flight performance is great.

The recommended options are mostly acceptable to achieve quality maps through a service like Propeller. We recommend adjusting front and side overlap to 75% and setting the resolution to the highest available—for the P4P it’s 3:2—so you’re not cropping out parts of the image.

Processing, measurement, and visualization software

Processing photogrammetry is a resource-intensive process and requires a lots of technical knowledge to do it, meaning both powerful software and skilled personnel are necessary. Would that time be better spent doing other work on the quarry?

Cloud-based applications (a.k.a. software that doesn’t just live in your desktop) are the most cost effective ways of leveraging powerful computing that also scales well and requires no installation or maintenance. Having your data be device-independent also means easier collaboration and sharing.

For a deeper dive on starting a drone program on your quarry, download our ebook Drones for Aggregates: The Beginner’s Guide: