Photogrammetric Processing 101: To Self-Process, or to Not Self-Process?

Considering whether to offload your photogrammetric processing with Propeller or self-process your drone data? Here’s five questions to think about:

- What’s my budget?

- How much data am I processing and what kind of turnaround does my worksite require?

- What are my data security needs?

- Who needs the processed data and in what file formats?

- What functionalities do I need from my data?

Drone surveying came about to resolve one age-old pain point: the amount of time it took to collect accurate site data. Before, worksites had to choose between collecting survey data quickly or accurately.

Traditional methods—walking the site with a base and rover, shooting points—took days (sometimes weeks) for larger sites and the aerial alternative required contacted pilots.

Amidst a skilled labor shortage, a surveyor’s time is a hot commodity. The time expense of traditional data collection left little time for site analysis, observations, or application of the findings.

With RTK drone hardware and PPK in play, surveyors have the ability to fly a site in a matter of hours and get accuracy down to 1/10ft. But aerial imagery is only a third of most survey outputs.

Most workflows integrate position and orientation system (POS) data, ground control points (GCPs), and drone images to produce the finished, measurable output. The output typically takes the form of a 3D map, and the act of synthesizing those three parts is called photogrammetry.

We’ve made it possible to offload the data processing burden that comes with photogrammetry. No more worrying about when (or if) you’ll have actionable data to work with. You’ll be able to track progress, track inventory, and manage your material movement the way you’ve always wanted.

Here are some questions to ask yourself when considering whether to self-process with software vendors like Metashape or have Propeller do the processing work for you.

What’s my budget?

We want you to find a formula that works for you, and you alone. Your needs are specific to the type of work you’re doing, and it’s important to find a solution that parallels those requirements.

Unfortunately, for most processing software, there’s a few hidden costs you need to factor in.

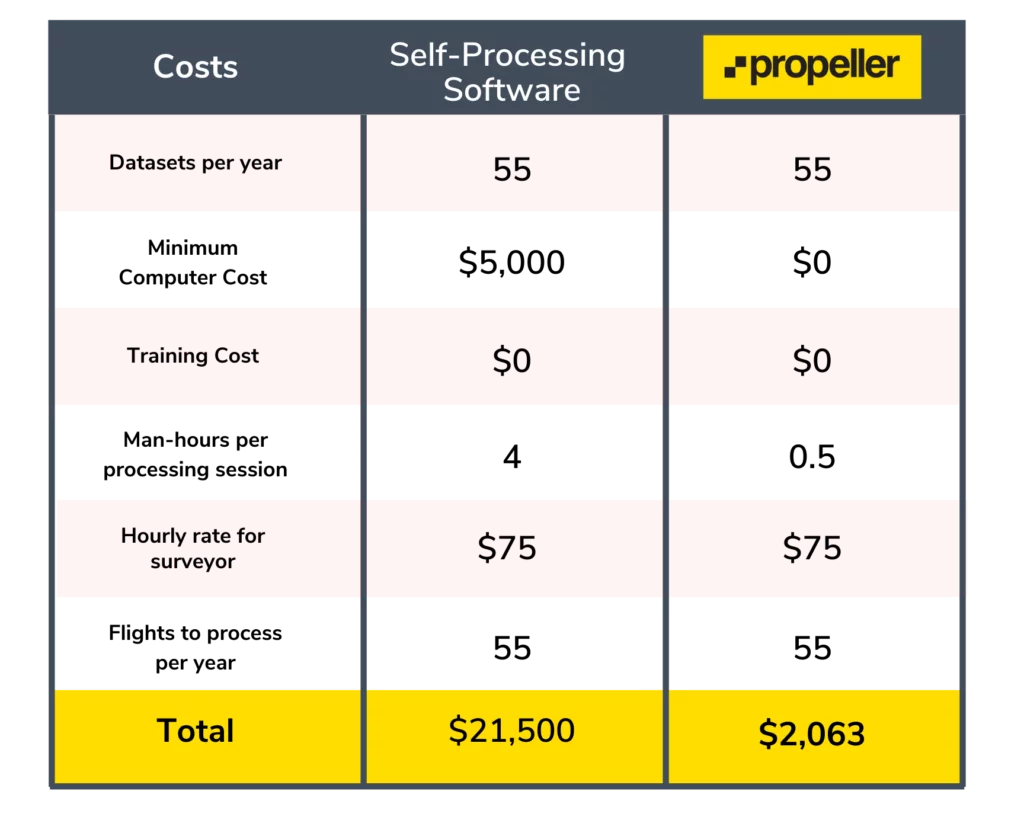

Say you decide to go with a self-processing product. If you want to avoid computer crashes and unexpected snafus, you’ll have to purchase a computer with enough processing power to support the large datasets you’ll be dealing with. Usually, these computers cost upwards of $5,000.

On top of that, self-processing demands a niche technical know-how, and that type of specialization comes with a high-dollar amount. If your surveyor makes $75 an hour and self-processing requires around four hours of your surveyors time every go around, it’s costing you about $300 every time you process a flyover.

And when you’re processing 55 datasets a year (which is on the low end for a large construction company), you’re dishing out an additional $16,500 a year just to access usable aerial data.

If you account for processing man-hours and computer hardware, you’re actually spending around $21,000 a year just to have your computers and surveyor’s bandwidth tied up while your data processes. This doesn’t even account for what you’re spending on a software license. Even when we factor in the cost of Propeller software, it’s the cheaper option (and not to mention the least stressful).

When you let Propeller do the heavy lifting for you, you almost cut your outgoing costs in half, you don’t have to worry about any of the vulnerabilities that come with self-processing, and your surveyor puts almost 24 days back on the calendar each year. This way they can get back to doing what they do best—analyzing site maps and making observations that keep you on-time, on-budget.

How much data am I processing and what kind of turnaround does my worksite require?

Like much else, photogrammetric processing falls across a spectrum, and that spectrum is dictated by the size and frequency of your datasets.

Deciding between self-processing and Propeller is ultimately a question of accuracy and flyover volume and those two things depend on what kind of worksite you’re operating. As you move across industries, accuracy tolerances shift. For example, one site may be totally fine with 1ft accuracy, while a reclamation job that requires a ton of earthwork needs accuracy down to 1/10ft.

The density of ground control points dictates accuracy, and the higher the density, the longer it takes to self-process a dataset. With smaller, infrequent data processing jobs, self-processing is the best option. You have more control over what the data is going to look like and the turnaround time.

On the flip side, when you’re in an industry like aggregates where your stockpile is your livelihood and you need up-to-date quantities at the end of each month, you’ll need to fly your site more often. The more data, the bigger the processing job. When you’re talking quantities, accuracy is the number-one priority.

For material movement, progress tracking, and a finer grade of accuracy, it’s best to offload the processing burden to Propeller, where each dataset is returned reliably within 24 hours of your most recent flyover, every time you fly. No questions asked.

What are my data security needs?

A lot of people think cloud processing (the kind of processing Propeller uses) is a black box, a mess of security concerns they can’t trust their data with. This isn’t the case.

To ensure the integrity of your datasets, we have an entire team dedicated to data quality control. This team helps you troubleshoot camera positions, lens distortion, and other blips you’d have to navigate on your own with self-processing.

On top of that, you’re saying goodbye to security vulnerabilities all together. One of the (many) benefits of storing things in the cloud is several impermeable firewalls of security.

With self-processing, you’re running everything off your own computer, which is much easier to hack than a cloud processing behemoth like Amazon or Microsoft.

Who needs the processed data and in what file formats?

Here’s one that’s often an afterthought—export formats. Export formats are the link between your processed data and other platforms.

After finishing up with the processing, most self-processing workflows require some data clean-up—editing point cloud data, removing certain features to eliminate any noise, flattening buildings, etc. In order to do this, your processed dataset needs to be in a file format that’s compatible with whatever secondary software you’re using to do the editing.

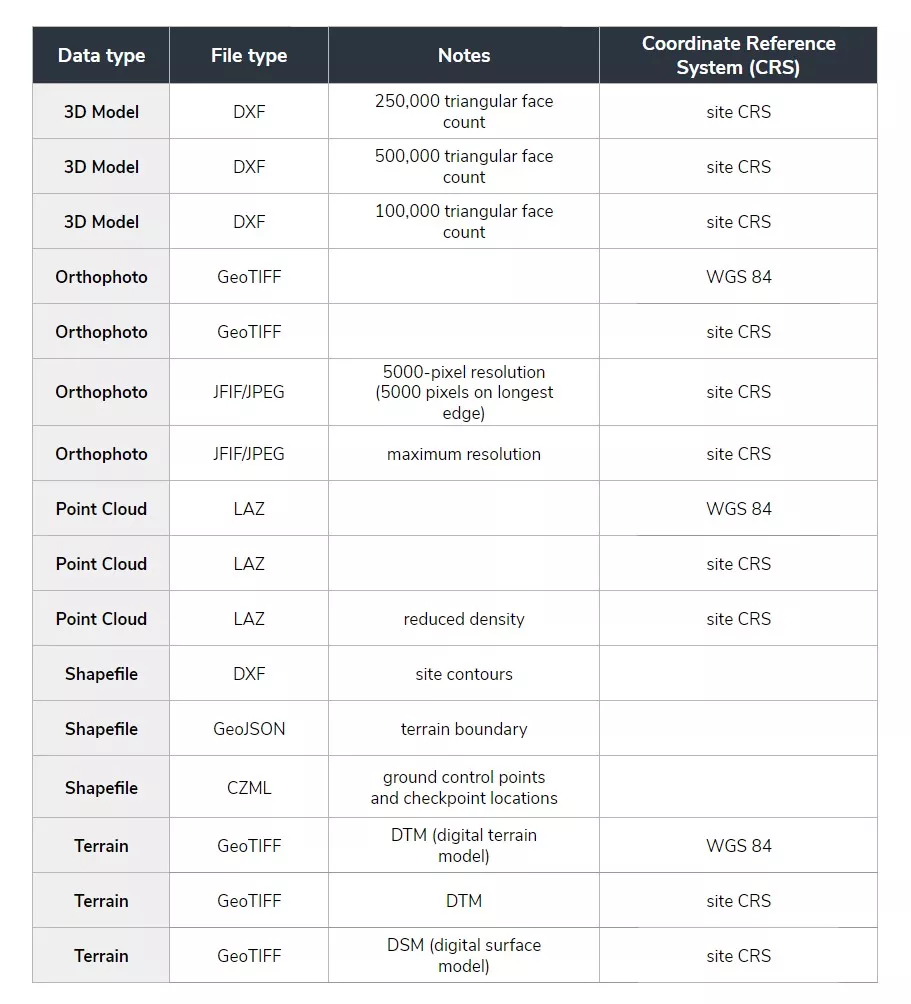

With Propeller, you get a whole slew of export formats to fit a variety of workflows, as you can see in the chart below.

Propeller isn’t a data silo. You can import your data in geoTIFF, DXF, DWG, KML, and KMZ, or export as JPEG, TIFF, DXF, or LAZ files and always have the formats you need for existing workflows.

Coordinate reference systems (CRSs), the geospatial dimension of your dataset, is also another factor to consider here. Processed data is nearly useless if it isn’t using the same CRS as the rest of your worksite.

Many self-processing solutions do not accommodate local grids, which requires significantly more work on the surveyor’s part. Propeller allows you to use whatever CRS you want to avoid compatibility issues all together.

To eliminate some of the runaround of post-processed editing, we also have a terrain editing feature that helps you get rid of visual obstructions.

What functionalities do I need from my data?

In other words, what do you hope to accomplish with your data once it’s processed?

Will you just need to visualize your data or are you looking to make real-life measurements regarding your material movement and progress?

This is where you need to think of your processing as singular step in a much larger workflow. The end must determine the means.

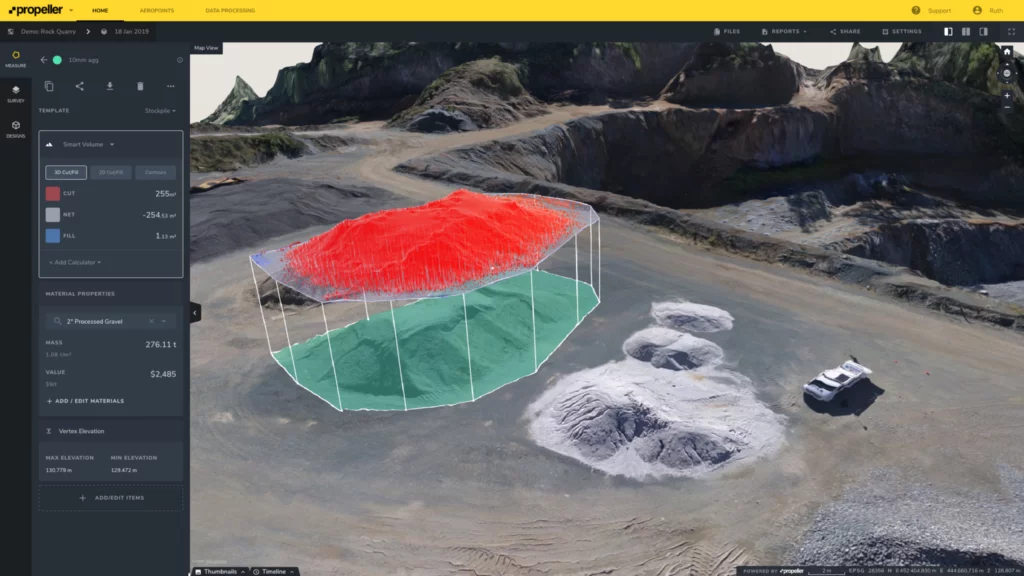

After Propeller processes your data, you have a wide range of ways to apply the data in the Propeller Platform. First, you can explore a 3D map of your site to see how far you’ve come, zooming in on certain site features from a viewpoint you never could achieve from the ground.

Post-processing, there’s an entire interactive toolbox at your disposal. In just a few clicks, you gain access to on-screen calculators and analysis tools that help you measure volumes, surface areas, road grades, elevations, and cross-sections.

Here’s ten things Propeller gets you post-processing.

No more stress. Upload your flyover data to process and forget about it.

If we reduce this entire article into one takeaway, it’s this: Processing can quickly turn into a full-time job, and with a full-time job you’re paying benefits. You’re paying for human labor, and all the risk involved with that.

Every worksite, whether it’s a mine or a construction site, intends to turn as large of a profit as possible, while keeping everyone safe and efficient. And from a high-level perspective, you’re always looking for opportunities to grow revenue and expand your operation. Expansion means more data, and more data means additional resources (additional payout).

Suddenly, all that time you saved by switching to drone surveying is expended during self-processing, and you’re back at square one.

Most Propeller customers make the leap from self-processing proactively, so they never get to a point where their datasets become too large and too frequent to handle. The best part about Propeller is that it molds to you, so you’re never paying for more than you’re getting.

No more putting everything on hold when the one person that knows how to process goes on vacation, no more tying up your computers and surveyors for days.

Upload your flyover data, click Process, and forget about it. Processing with Propeller is the path of least resistance and the fastest route to 3D site maps.

Stop stressing over self-processing. Let Propeller process your drone data for you. Make the switch today.

Keep reading:

10 Ways Drone Data and Earthwork Software Can Make Your Next Project a Success

The Most Common Questions We Get From Propeller Customers Before They Commit

Keep Your Drone Data “Grounded” with Permanent Ground Control Points