Manage Tailings Dams Better with Drone Surveying

Tailings dams are some of the biggest man-made structures in the world. But they are plagued by too-high failure rates and a shortage of available data. Their size and their potential for environmental hazards make them difficult to survey and monitor—if they’re monitored at all.

Tailings dams are a common sight on mines, especially metallurgic or coal mines. These giants are made from earth and can cover entire square miles. They serve as waste storage for all the contaminated liquid used during the material refining process. This means that, depending on what you’re mining, tailings dams can contain dangerous poisons, like cyanide in the case of gold mining. They’re dusty, large, and unpopular on the worksite.

Surveying tailings dams with traditional methods

When such dams break it can spell catastrophe for the surrounding environment, not to mention site operations itself. But due to their layout and inherent danger, it’s almost impossible to survey them with traditional base-and-rover methods, where you have personnel physically walking the area.

Depending on how much evaporation has occurred, it’s risky, but you can get a very loose estimate of the incline by shooting a few points in the basin and measuring the slant, like a beach shore, and extrapolating numbers from there. These calculations have huge margins of error, and can endanger personnel. Other parts of these dams can be impassable, depending on where they’re built.

Some mines use things like radar and lasers to measure their tailings dams, but this also presents the problem of time and money. (Systems can cost millions of dollars.) You have to take measurements from each individual side of the dam. It can take half a day to obtain this single total measurement.

Another alternative is shooting to prisms imbedded in the tailings dam (if they exist on your site) to see how far they’ve moved. But that means, you’re only capturing small parts of the wall, not the whole thing.

Drone surveying for tailings dams is easier, safer, and faster

When you choose to monitor your tailings dam with a drone, you are immediately reducing the risks to surveying personnel. No longer do they need to be in such close proximity to dust and dangerous substances associated with the area. Drone surveying can be done from line-of-site distance alone.

Further, because drones are almost entirely automated (flight-planning apps take care of all the physical flying), they don’t require the same kind of special training and education needed for traditional equipment. Drones are also orders of magnitude less expensive. Widely stocked craft, like DJI’s Phantom 4 Pro, are recommended are ideal options for most sites.

Instead of taking most of the day to gather your data, you can fly your drone and capture all the data you need in a mission that takes an hour, depending on the size of your dam.

Establishing ground control on your tailings dam

Ground control is vital to drone surveying. It ensures accuracy and allows for data validation. But whether you’re using known points or moveable GCPs like Propeller’s AeroPoints, you face the singular challenge of distributing ground control properly.

With AeroPoints, you can place them around where it’s safe to tread in the dam. There are some challenges as you get close to the waterline, but with some finagling, you can get acceptable accuracy.

But there still is simply no way to lay out points on all the necessary places on these wide pools. But there is an alternative: PPK drone surveying.

Drone surveying using PPK (post-processing kinematic) methods essentially turns every drone photo into a GCP because it is geotagged with high accuracy. All you need for a PPK workflow like Propeller PPK, is one AeroPoint to serve as a passive base on ground level.

The best part? You can set that AeroPoint down beside you, on safe ground. (If you’re working on a local grid, however, be sure to put that AeroPoint on a known point.) Learn more at propelleraero.com/ppk.

See your tailings dam’s status with 3D surveys

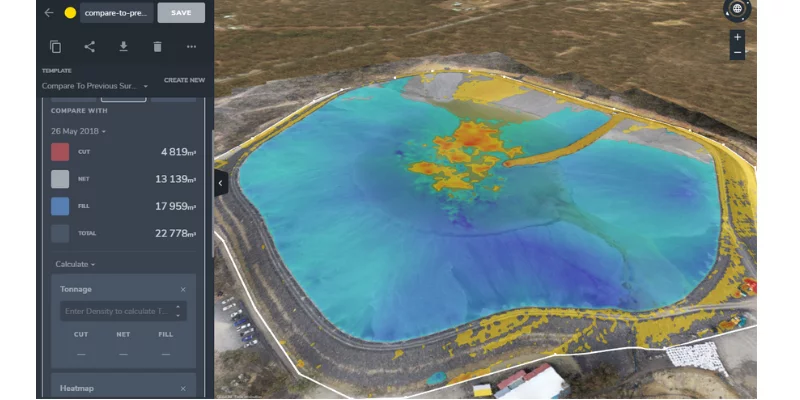

Once you’re finished with your survey, you simply upload your data to a cloud-based processing platform, like Propeller, and all the photogrammetry and rendering is done for you.

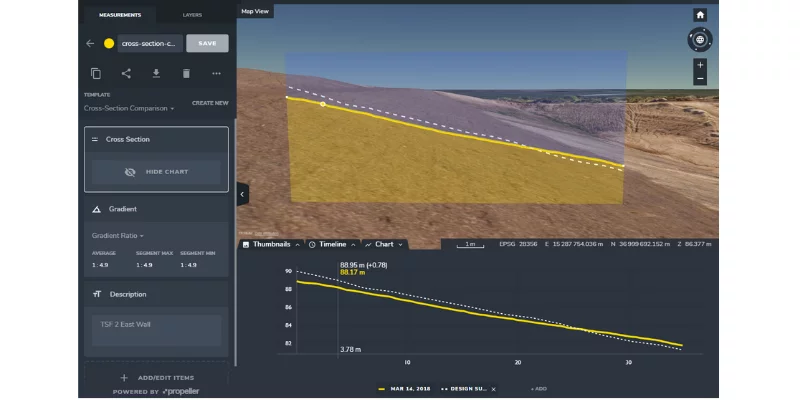

Typically, you get your survey back quickly. For Propeller, it’s finished in 24 hours. You can then view and measure your tailings dam in 3D. With just a few clicks, you can see volume numbers and locations where there’s more or less material in your dam.

Since drone surveying is cheaper and faster, you can also survey more often. With more data, you can track the fill level of your tailings dam over time and see when you’ll need to build up the walls.

Preplan for big expenses with a timeline of data

On any mine, expanding tailings dams means a huge capital expense. With the old methods, there was little warning of when this retrofit would need to occur. No one wants to be surprised by a project and bill like this. But with drone surveying and visualization software, you can know in advance where you are and when you’ll need to start making changes.

Platforms like Propeller also allow for design surface uploads, so you can not only track everything to spec, but make sure that next addition is built to spec. Use this data to spot problems before they become expensive.

If you’re working on an expansion, monitor contractor progress and productivity with visual tools everyone can understand and use.

Stop small issues before they become big problems

If a tailings dam fails, not only can it cost lives and ruin the local environment, it can mean huge fines and possible prosecution for the mine itself. It’s a simple solution, but implementing a regular monitoring process with the right tools can go far to protect against disaster.

Using drone surveying and visualization platforms like Propeller, you can get eyes on these dangerous areas without putting your people at risk. Do inspections and checks more often because the hardware and software is easier to use and more affordable than traditional methods—and, as we discussed above, it’s the only feasible option for some sites.

Having the data to track the life of a tailings dam means you can see how the structure is holding up against design, when you need to add more walls, and what material is sitting where.

Interested in learning more about how to start a drone program on your site? Check out our latest eBook. Download your copy today!