Introducing Composite Surveys: Streamline Mapping of Large-Scale Sites With Automated 3D Model Stitching

At Propeller, we know the decisions you make are only as good as the data you have at your fingertips. That’s why we’ve made it our mission to help earthworks teams accurately visualize, measure, and report on an entire worksite—all with less time and effort.

This week, we’re thrilled to announce our latest feature, a game-changer for large worksites that’s unique to the Propeller Platform: Composite Surveys.

A: A composite survey is one large 3D model made up of multiple smaller surveys stitched together. Composite Surveys make it possible to fly a small, active section of your worksite and merge it with other surveys in the Platform to form a complete and up-to-date view of the whole site, without needing to fly the entire site every time.

What this means to you: easier access to more frequent survey data for accurate tracking and planning of large-scale earthworks projects, like highway jobs, rail corridors and mass haul projects.

Get a complete, up-to-date model of even the largest worksites

Think of Composite Surveys as fully automated image stitching—a way to combine up-to-date maps from small, active sections of a large worksite into a meaningful whole. This way, you get the full site picture you rely on without spending hours (or even days) re-surveying inactive sections or manually processing cumbersome datasets.

By breaking a large site into smaller parts, you can upload and merge smaller sections to combine 3D surveys—as they change—into one seamless model of the entire site, no matter how large.

- Create and view a complete model of your site by merging up to 25 surveys using a simple workflow

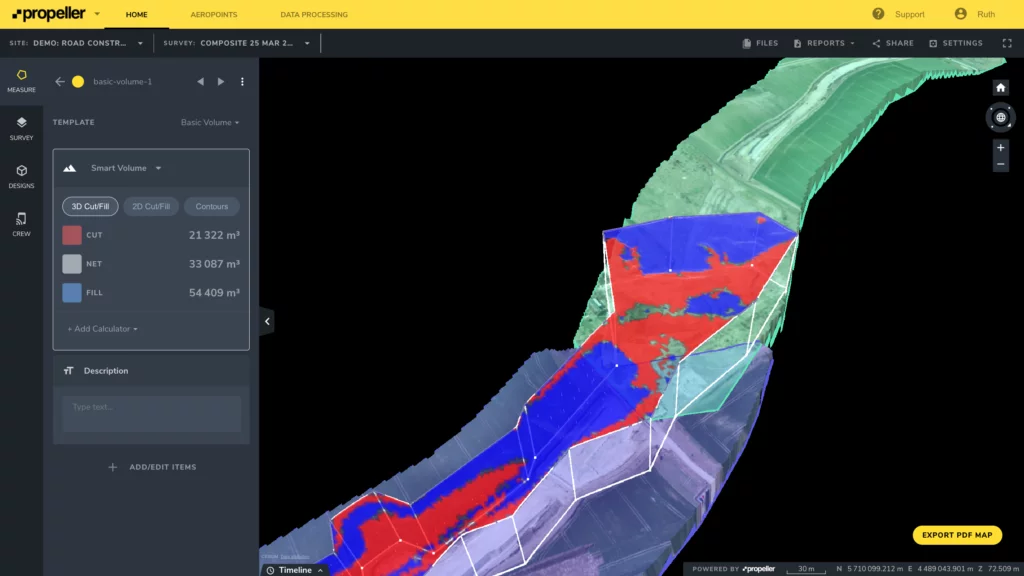

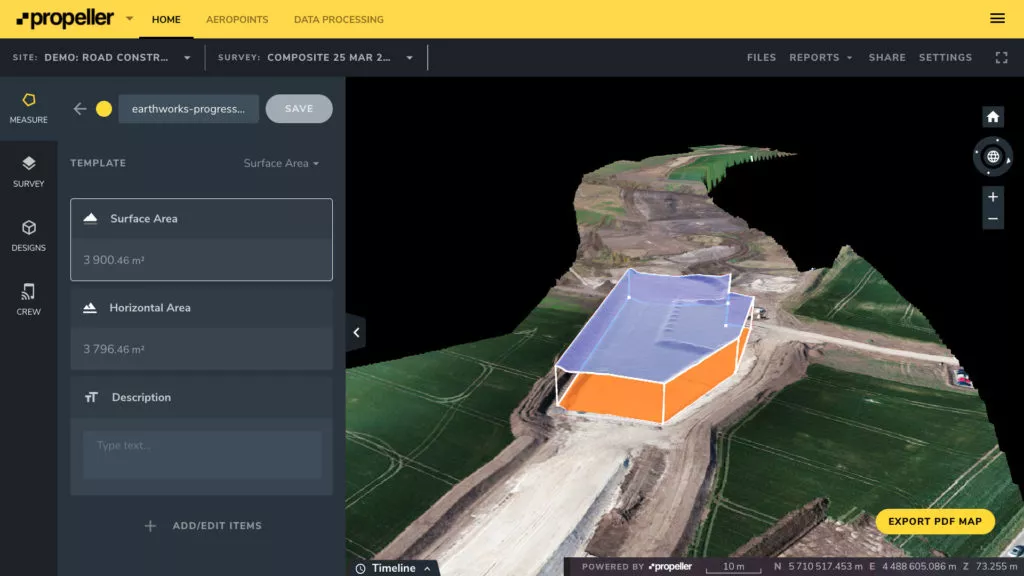

- Measure and track progress against previous survey data and final grade across the entire site using the Platform’s measurement tools. Calculate volumes and measure distance in a just few clicks, visualize against design, and document progress

- Empower others on-site by providing easy access to an unlimited number of users

- Update your composite 3D maps as your worksite changes

Do a week’s worth of work … in just one day

During the earthworks phase of any project, worksites change on a daily or even an hourly basis. Surveyors, supervisors, project managers and engineers rely on accurate data to prevent errors and confidently make smart decisions about what comes next.

On large worksites like highways, rail corridors and mass haul projects, getting easy access to up-to-date survey data is challenging, even with the latest drone technology.

Capturing a complete picture of the full site can take surveyors up to a week to complete. The time and resources required to make updates limit how frequently a site can be surveyed—and, by extension, the reliability of the data.

There are three main headaches when it comes to maintaining accurate models of extensive earthworks projects:

- Long flight times: Very large sites might require several drone flights to capture, which can’t be done in a single day. Between maintaining line of sight, battery life, and flight speed, simply capturing the necessary images can take two or more days to complete.

- File size: Once these sites have been flown, you’re left with massive datasets that take hours to upload. If you have a slow connection, it could be days before your data is uploaded and processed.

- Inactive areas: Your entire site probably isn’t changing all the time, but the inactive areas must be surveyed just as often as the active ones so you aren’t left with an incomplete model that’s missing data.

For Survey Managers and Engineers who rely on accurate data for reporting, tracking, and planning work on site, limits in survey frequency equate to limits in the value of the data itself.

Enter Composite Surveys.

It’s not magic, but it sure looks like it. Merge datasets from up to 25 surveys with the click of a button, and get results in less than 30 seconds.

A: All surveys, including Propeller processed surveys, pre-processed surveys and point cloud uploads.

Seamless stitching, seamless workflow

Once the merge is complete, you can use all of the Propeller’s measurement tools on that surface, making Composite Surveys the first feature of their kind.

Just plug and play with automated stitching, or manually edit the boundaries between individual surveys by clicking and dragging. Terrain cleanups applied to the surveys in your composite get applied automatically too, so you always have the peace of mind that comes with knowing your measurements are made against the most accurate data.

Other software with image stitching capability doesn’t fit seamlessly into a drone surveying workflow. It requires additional time to manually import, process, and export cumbersome datasets—not to mention costly training and licensing.

With Composite Surveys now a component of Propeller’s PPK workflow, Survey Managers and Engineers on even the largest worksites can have easy-to-access, reliable data at their fingertips.

Here’s an overview of the benefits our customers have reported:

Time savings for Survey Managers

Now, Survey Managers on large worksites can complete a week’s worth of work in a single day. The ability to quickly merge 3D surveys in the same platform where they track, report and plan work frees up surveyors to focus on the work that matters most, and not on manually gathering and processing data.

Easy access for Engineers

Engineers benefit, too, since they can now easily see a complete and accurate model of the entire site. They can better track material movement, monitor progress, and plan for the future—no switching back and forth between separate survey datasets needed.

Increased site visibility for all

Visibility across the whole site means that teams can monitor and plan work in a more efficient way. In a real-life example, one Supervisor could see that another team had a surplus of railway ballast in their section. Rather than wasting money and time ordering more, this Supervisor could quickly and efficiently repurpose existing material.