How to Improve Earthwork Estimates with Drone Data

As an estimator in earthworks, you have to take many things into consideration when placing a bid: materials, labor and equipment required, different quotes from different subcontractors and suppliers, and the quality of all of these goods and services.

Your estimates must be competitive while maximizing profitability—an extremely difficult balance to strike. Your decisions can make or break a tender if the price is wrong or the quality isn’t high enough.

There are some great tools available to you (Trimble Business Center, AGTEK, Civil 3D, etc.), but their outputs are only as good as the information you feed them, and topo data from clients (if any) can often be wildly inaccurate.

Getting your own earthwork surveys is the best way to trust the data. However, surveyors are expensive and busy. It can be hard to justify their cost and, if you can, it can be difficult to get them on site when you need to. This all leads to adding a “fluff factor” to measurements of 5–10%. This approach may have been sufficient in the past, but it’s increasingly challenging to remain competitive using this methodology.

Today, you need accurate data to win bids, and you need to be able to collect it yourself. With a drone data analytics platform like the Propeller Platform, you can collect your own accurate data to produce high-quality, competitive submissions—and win more bids.

Check out our free webinar: Five Ways to Resolve Disputes (and Drive Profits) on the Worksite

Ensure Your Earthwork Data Is Accurate

Use Ground Control

To ensure you earthwork data is reliable and accurate when surveying with a drone means using appropriate ground control. There are two options:

- Traditional ground control—Features or marked points recorded with a rover by a qualified surveyor.

- Smart ground control (AeroPoints)—GPS units that use PPK to achieve survey-grade accuracy.

Since you work on multiple sites, it’s likely you’ll want to use smart ground control, so you don’t need to rely on anyone else to get your data.

Capture Your Data

Check out our series of blogs on how to capture accurate drone data, in detail, in various circumstances. But no matter the situation, the underlying concepts remain the same:

- Ensure that your ground sampling distance (GSD) remains smaller than your desired survey accuracy.

- Ensure you have 75–80% image overlap.

- Avoid imagery of things you don’t need mapped (sky, distant objects, etc.).

Conduct Quick, Accurate Pre-Bid Surveys

It’s hard to overstate the importance of having data you can rely to produce accurate bids. Because drone surveying is simple and nontechnical, you can do all your pre-bid surveys yourself and avoid the fluff factor. Cut out the cost and time of a third-party surveyor; there are no traditional “boots on the ground” needed.

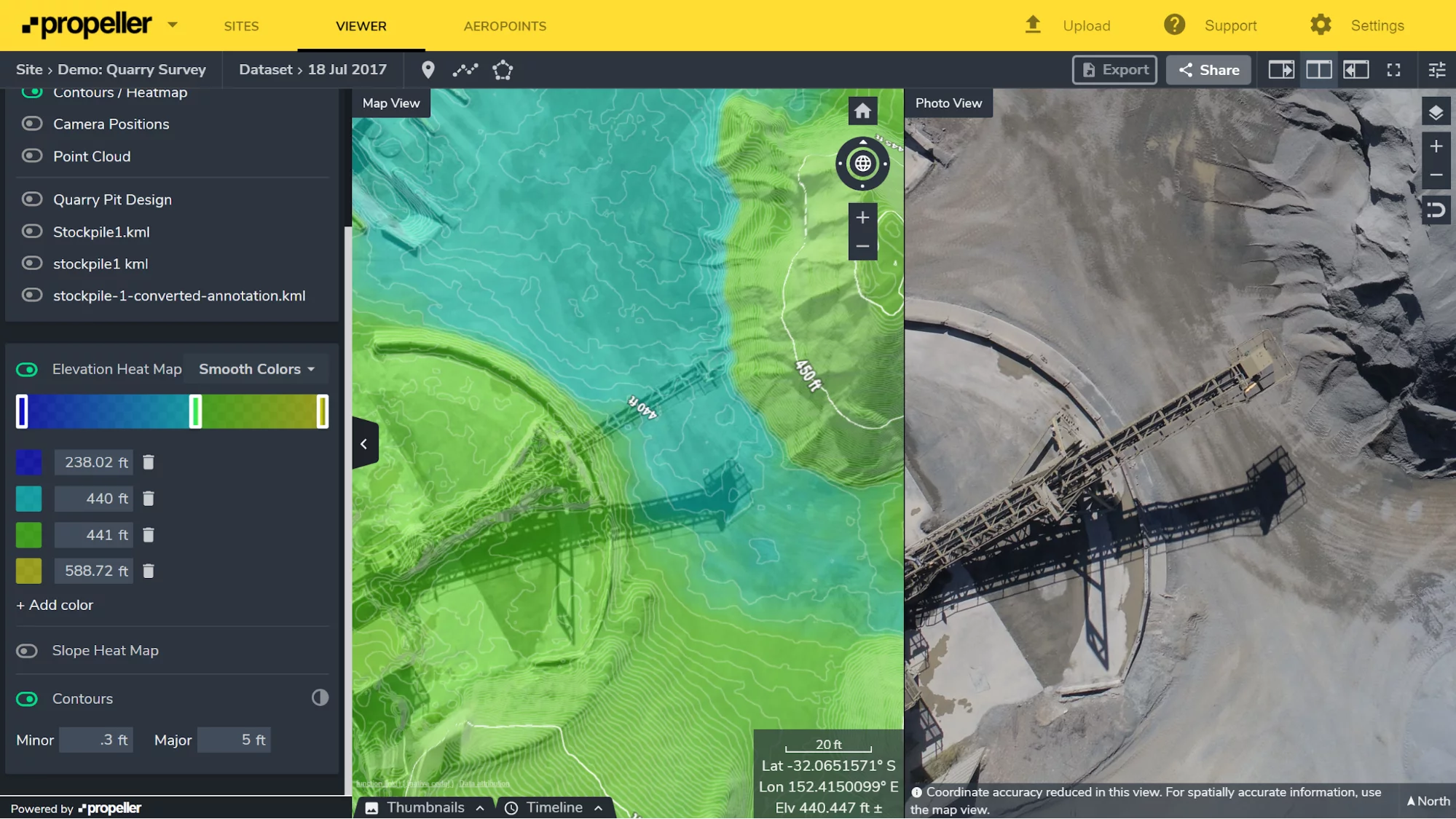

Once you’ve captured your survey, you can process that data in an estimating platform to get all the info you need for the best bid. And with browser-based platforms like Propeller, clunky desktop software is a thing of the past. Propeller’s intuitive visualizations allow you to have a visual conversation with your prospective clients as well as your own team.

In addition to the measurement and collaboration tools we’ll talk about further down, platforms like Propeller also clean up your data for better usability. For example, removing vegetation, vehicles, buildings, and other obstructions above bare earth take just one click on the corresponding filter. (If you’re processing it yourself, this is where a lengthy process of trial and error begins.)

Use Design Surfaces and Linework Overlays To Avoid Unnecessary Import/Export

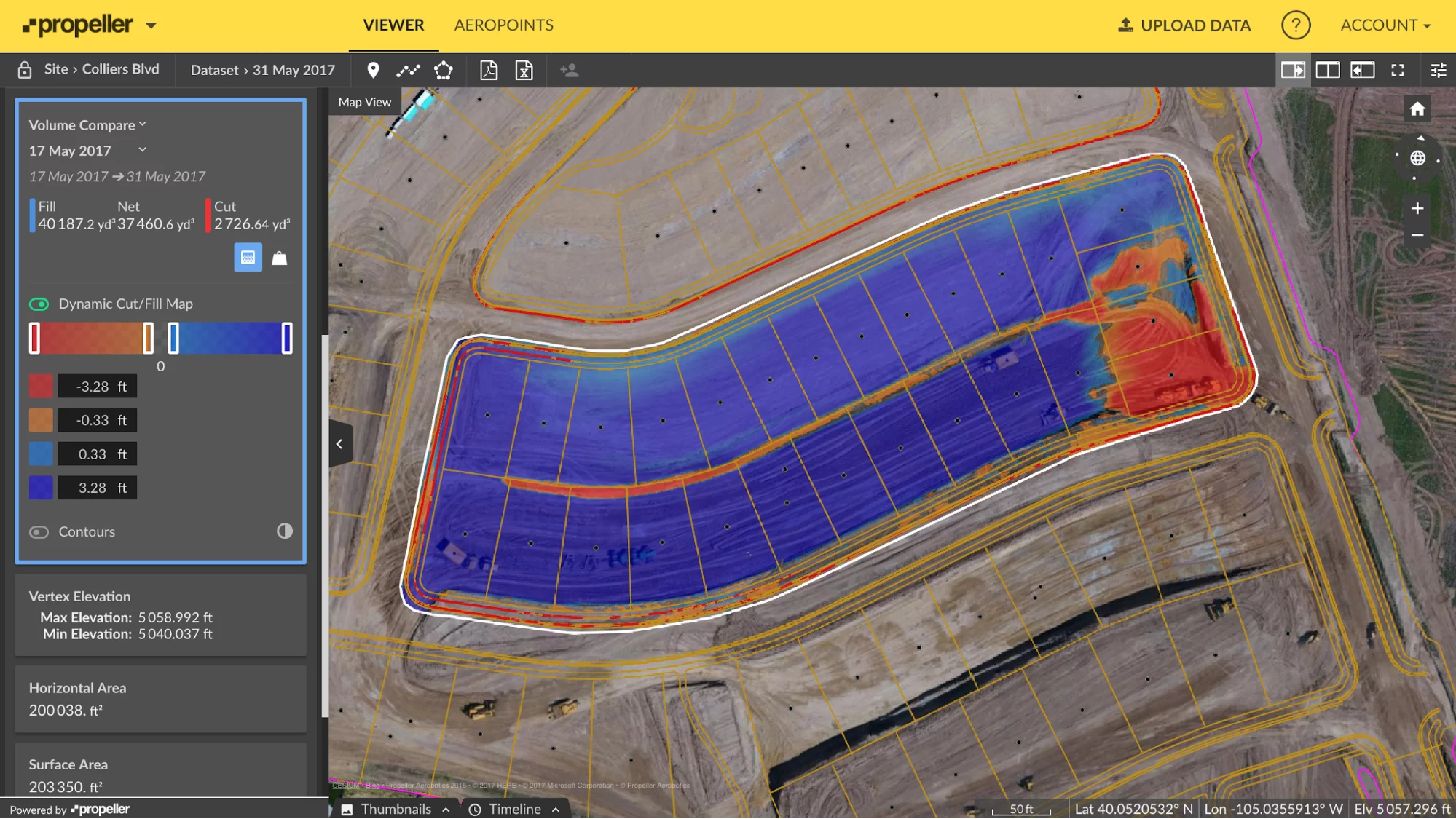

Propeller allows for easy uploads of design surfaces and linework. If a site’s design surface is accurately georeferenced, you can load it into the platform and do a comparison against your initial topo to see how much you’d need to bring in or take out to hit the final design. For linework, you can easily measure a specific section of the site by turning linework into annotation boundary (see below).

Reliable and instant earthwork volumes allow you to see how much you need to import or export to get the job done. Knowing these exact values up front means you can better balance your site.

In the picture below, you can see 37,460 cubes are needed. With that number, you can work on balancing your site by getting some or all of that material from another part of the site.

Estimating Platforms Enable Easy Reporting

At the end of the day, you also need to be able to present your earthwork survey data in an understandable way. No one is going to trust bids they can’t make sense of. When you use drone technology for estimates, not only are you providing you clients with real-world imagery they can understand, you’re also simplifying reporting and analysis.

With Propeller, you can export PDF and CSV reports on all your survey data. These provide a paper trail for who did what work when and a useful reference when meeting with your own team or your clients.

Further, you can also grant platform permission to a client in so they can see the 3D survey in action themselves.

Drone Technology Improves Your Estimates and Your Workflow

Job estimates are always going to be a part of the industry, but the technology that produces them will, and has, improved. Drones and data processing platforms are simply raising the quality of the baseline for estimating. They put the power to measure a site is in your hands. Relying on a client’s suspect data or paying a third party to survey is no longer mandatory.

As we’ve seen, not only do estimates take less time with drone technology, they’re just as accurate as traditional methods. Incorporating a drone and a processing platform like Propeller into your regular workflow can save you money and help win more bids. It also provides detailed, easy-to-understand documentation, site visualization, and rock-solid numbers.

Bonus case study: Get pre-bid topos without flying twice

Now that you understand the basics of picking out drone hardware and earthwork software, and how you can improve your estimates, we’ll dive a little deeper into how you actually get those pre-bid topos yourself.

Pre-bid topos are on most contractors’ nice-to-have list, but nobody wants to waste a survey crew’s day on a job they’re only bidding on.

After all, if you spend time doing a pre-bid topo and don’t get the contract, what was it for? But if you could get up-to-date as-found topo, you’d have an edge over competitors.

Propeller can provide you with an accurate preconstruction topo that doesn’t mean sinking more time than you want into the task. It’s simpler than you think. Fly a site once, pre-bid, and have all the information you need.

Get your pre-bid topo quickly without hiring a third-party

This is just what Phoenix-based Buesing Corp. found to be most effective when doing their own pre-bid topos.

“With a drone flight, we can go into a site before a bid or during precon and say with confidence how much dirt is there,” said Buesing Corp.’s GPS Manager Rio Byman, who frequently oversees bidding and site topos. This process takes a couple of hours at most.

Before using drone surveying, Buesing would typically pay for grid spacing from 25- to 100-feet using traditional surveying methods, depending on the site.

“For a flat site, about 100 acres, it could take us two hours to do a precon bid topo. Maybe $1,800 for the survey,” said Byman. But these numbers depend on the site’s accessibility. “If the terrain is rough and if the site hasn’t been grubbed yet, it could take us two to three days and around $5K to 6K to hit the same size area.”

Time and cost can be a problem, but the grid itself can also introduce problems on a new job. Depending on spacing, it’s sometimes possible to miss important breaklines and features or additional dirt hidden under vegetation. In such cases, surveying by drone might be a better option.

A ground topo captured by drone is extremely dense, as millions of points are gathered in photogrammetric drone surveying. Without that kind of detail, it “can lead to time-consuming disputes over how much dirt was on site, and from there it’s word against word,” cautions Byman.

Want to see exactly how Propeller can help you track earthwork progress better and improve your estimates? Build out your own demo of the Propeller Platform.

Read more:

How Drones Help with Conflict Management in Construction

Using Propeller, Drone Surveying for Smarter Pre-bid Topos at Phoenix-based Buesing Corp.

Drone Program ROI: How Grade Tech Saved $1.7M (and Counting)