How Progress Tracking Makes Mine Reclamation Easier

The mining industry is a complex system of moving parts that don’t always sync up the way they should.

Not only are mines (both surface and underground) navigating extraction—blasting the deposits and processing the minerals—they’re also constantly undergoing reclamation.

Mine reclamation is the process of restoring mined land to pre-extraction conditions. When you reclaim land, you’re minimizing any adverse impact you’ve had on the surrounding ecosystem.

The kicker: you need an action plan for remediation before you even start mining.

The road to remediation is long, but by maintaining a visual and interactive 3D record of your worksite from development to decommission, it’s a whole lot easier. Let’s dive into the specifics.

What makes mine reclamation difficult?

Regulatory entities like the Office of Surface Mining Reclamation and Enforcement (OSMRE), a branch of the United States Department of the Interior, want insurance that you’ll be able to successfully decommission and repurpose the land before you start blasting.

Typically, there are two approaches: reforestation or new development. Either way, there’s a lot of documentation and work that goes into successfully rehabilitating the mined land.

With reforestation, much of your time is going to be spent replicating the original contour, laying the medium that supports optimal vegetation growth, and ousting byproducts.

Alternatively, with new development, you could be negotiating with municipalities, deciding what grade they need to build a wastewater treatment plant on the reclaimed land and how long it will take.

Unfortunately, there’s no way of knowing exactly how long your mine will be active and how much extractable material lies beneath the surface, which complicates the remediation timeline. In fact, the typical lifespan of a mine is five to 30 years, though there’s a strong minority that have kept operations running for more than 100 years. And, an individual mine can produce more than 100 million tons of waste each year, depending on the size.

Since the extraction timeline is broad and largely driven by guesswork, the reclamation process is as well. And, even though all timelines are loose approximations, everything is time-sensitive.

On top of the physical work and man-hours that go into reclamation, there’s a whole other beast to tame—keeping everyone informed.

Returning the land to a usable state requires a wide array of participants that includes stakeholders, governmental agencies, your team on the ground, developers, contractors, and more.

Comprehensive progress tracking is the best way to reduce ambiguity and increase transparency in the reclamation process. A less time-intensive, objective way to document progress on your mine is drone surveying. Drones capture everything happening on the ground without the subjectivity of the human eye.

Progress tracking with aerial data

The next factor in the reclamation equation is accuracy—how accurate is your progress tracking?

Accuracy is a byproduct of frequency, and traditionally, frequent surveying came at a high price point. Drone surveying alleviates the cost burden and yields high-resolution aerial imagery you can then process into a digital 3D copy of your mine. Because it takes less time and less expenditure, you can survey more frequently.

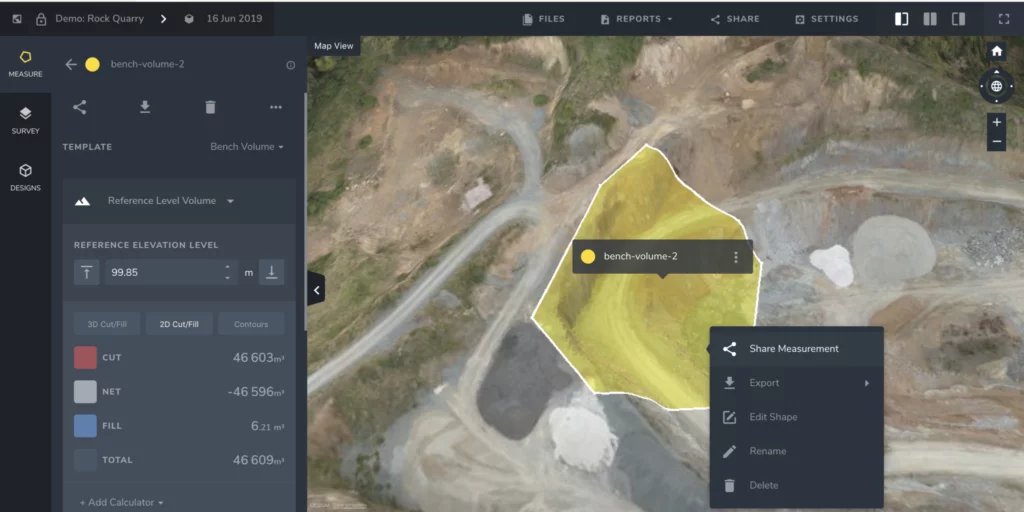

Processing platforms like the Propeller Platform use your drone inputs to engineer a detailed and interactive output.

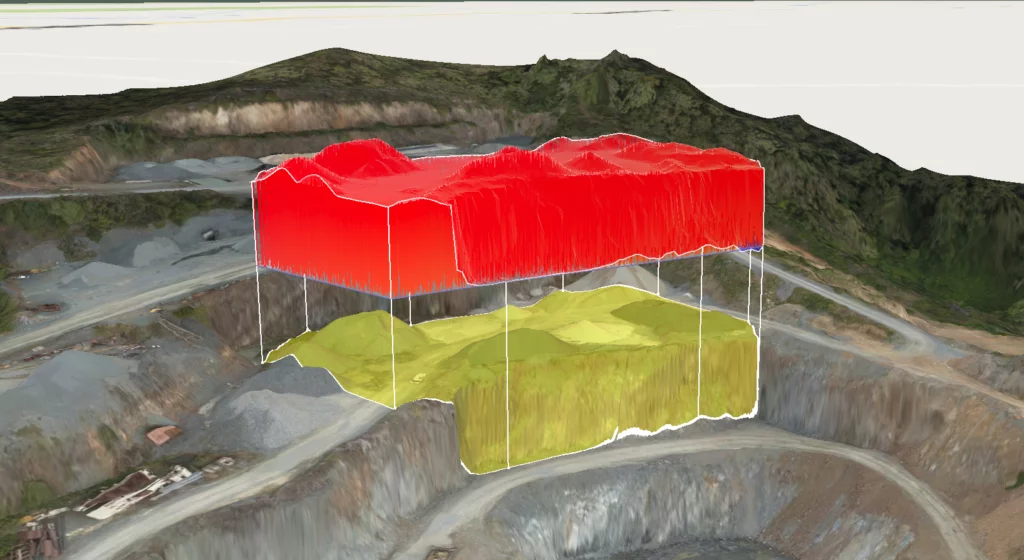

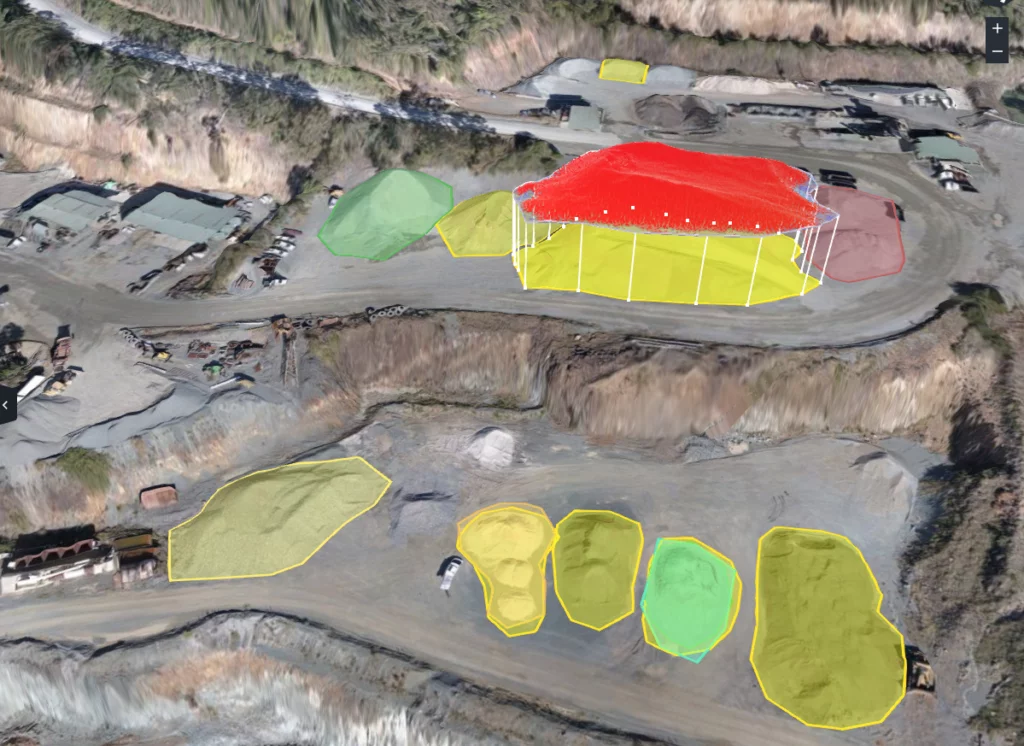

Using the 3D visualization of your mine, you can layer datasets to compare material movement between flyovers. You can also layer aerial data against design to gauge how far you’ve come and use cut/fill calculations to estimate how much extractable material is left from a blast.

Although cut/fill measurements may seem irrelevant to reclamation, all processes have tangential impact. It’s a chain reaction. Once you’re able to estimate the extractable material to a greater degree, you can be more strategic with your blasting plans.

If you’re designing future blasting plans around the historical extraction data, your blasts are more focused, minimizing waste and environmental impact.

Cut/fill measurements also deliver insight into tailing volume (what’s left over after you process ore) and waste rock (what’s encasing the ore as it’s extracted).

It’s a simple equation. If you know the ratio between waste rock and viable ore is two to one, and you used the Propeller Platform to find that there was X tons extracted from the most recent blast, you can easily approximate your waste volume.

Progress tracking with 3D site renderings lays the foundation for data-driven remediation. You have eyes on all material movement, whether it be waste rock or iron ore.

When we asked a technical services lead at Orica, one of the world’s leading providers of commercial explosives and blasting systems, about the use cases of drone data, she said the first thing she does each month is look at the progress they made the month prior. Using the Propeller Platform, she looks at where crestlines are falling for blast progress and what volume of material they’ve moved.

So, how does this make reclamation easier for mines? It’s an opportunity for visibility in an industry dominated by blind turns. Accurately calculating how much material you’ve removed introduces a new layer of certainty to the reclamation timeline.

With a month-by-month (or week-by-week depending on your tonnage) record, it’s easy to pinpoint site vulnerabilities. This could be how much backfill you’ll need to restore the grade to its original state, problem areas that will require more ecological attention, or a safety hazard that could potentially cause a hang-up.

Getting the right information in front of the right people

As we mentioned before, there’s a lot of people involved in the reclamation process, and they all have different objectives. Regulatory agencies want to protect the environment, site managers want to turn a profit, and your team wants to operate efficiently and safely.

Drone data is the perfect bridge between all parties because it’s not skewed to better serve a singular channel. Instead, it’s one objective source of truth that benefits everyone’s agendas.

After you upload your aerial data to the Propeller Platform, you can share your progress reports with whoever needs to see them. As team members on the ground leverage the platform to plan future blasting and monitor haul roads, your upper management can monitor progress and material movement from afar. It’s a matter of better estimates and fewer hours on the clock.

As your mine reaches its end of life, the 3D renderings of your site will become extremely valuable to the contractors repurposing the mined land to build a school, retail complex, or airport. They’ll be able to track the land degradation as you continue to extract, forming their approach proactively.

Also, for those moments where there’s a conflict escalating and work is in question, you have an entire unimpeachable record of progress to bring about a quick resolution.

For more information on report sharing, here’s an article covering how the Propeller Platform ignites collaboration.

Transitioning from reactive to proactive

When it comes to mines, nothing is siloed. As you’re extracting, you’re prospecting, and while you’re extracting and prospecting, you’re working toward reclamation. It’s a tangled web of ever-changing timelines.

Moving forward, make a commitment to proactivity.

It may not be possible to predict the lifespan of your mine down to the day, but by actively monitoring your site health from an aerial perspective, you remove some of the reactivity from reclamation.

Using a dynamic, 3D visualization of your site, you can open the door for transparency and close the door on guesswork. The less guesswork, the easier the reclamation.

Want to learn more about how the Propeller Platform brings value to your mining workflow? Contact us today.