How It Works: PPK vs. GCP Drone Surveying

Post-processing and real-time kinematic workflows are widely available with the current drone technology on the market. However, for some, questions remain about what this technology actually is, how it works, and what’s best for your surveying needs.

To cut through the complexity, we’ll explain how PPK workflows differ from GCP-based drone surveying and how RTK plays into it all.

Ground control and traditional drone surveying

For traditional drone surveying, you need a sufficient number of known points to verify and “pin” your drone imagery to the ground. Standard drones without any GPS correctional processing are simply a vehicle for the camera.

If a drone’s position in the sky is not accurately geotagged, you won’t get reliable positional data from it. That accuracy comes from ground control, which is why even small errors in ground control setup can have significant repercussions.

Ground control points (GCPs) are known points marked and measured with a base and rover to gain better accuracy, or you can use moveable “smart” ground control points, like Propeller’s AeroPoints.

Using GCPs when surveying ensures survey-grade accuracy, but setup can be time-consuming on a large site.

Setting up ground control with AeroPoints

If you’re working with smart GCPs like AeroPoints, you need to place the hardware in an optimal distribution across the entire surveyed area. This method takes some time, but it saves on shooting points with a rover on foot and painting them for visibility.

Once AeroPoints are in place, the process becomes infinitely simpler. Activation requires only a single button, then they’re ready to start gathering GPS data. When your drone survey is complete, you gather them back up, and they automatically search for a WiFi signal to begin uploading their data to Propeller.

Onboard differential GPS has reduced the amount of ground control needed

RTK-enabled drones have the ability to track their own positions accurately, which regular drones lack. A PPK workflow is our recommended method for topographically surveying a site via drone for reasons we’ll explain. But first, let’s learn what makes these RTK and PPK technologies different.

How on-board RTK technology works

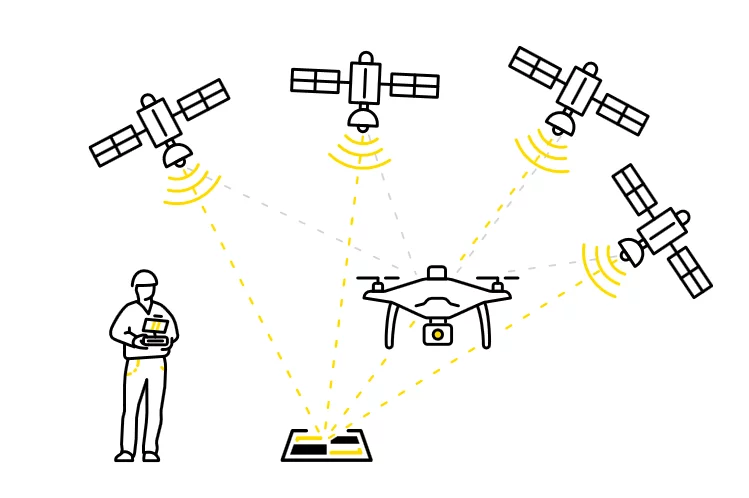

Real-time kinematic (RTK) processing on a drone records GPS information and geotags images as they’re captured during flight. The GPS location is recorded for the center of the image.

An active base station on the ground sends raw GPS data to the drone. Then the drone’s onboard GPS combines that info and its own observations to accurately determine its position relative to the base.

But to achieve this, the RTK drone must stay connected to the base station while it’s gathering data. Unfortunately, signal loss can occur during turns in flight, likely due to antenna orientation, and other instances. If this happens, while the drone tries to get a lock again, data becomes unreliable.

The difference between PPK and RTK

Now, you might be wondering where does PPK come in. This is where things get tricky because we’re not strictly comparing apples to apples. PPK isn’t hardware, but rather a different processing workflow using an RTK drone.

PPK stands for “post-processing kinematic.” The difference with PPK workflows is how we process base station data for correction and accuracy.

With PPK, the drone will geotag X,Y,Z coordinates to each image based on that on-board GPS unit. While this is happening, a base (be it a base station, an AeroPoint, or coordinate reference system network) is also recording positional information, but with much more accurate triangulation.

After the flight is over, those two sets of GPS data are matched up using the photo timestamp. Then the initial, less-than-accurate onboard GPS data is corrected, giving precise geotags for the imagery

While “real-time” technologies are appropriate in some situations, post-processing flight data using a PPK workflow brings an additional layer of reliability to your surveys.

What are the advantages of PPK drone surveying?

PPK drone surveying offers several advantages over traditional drone surveying methods that employ only an RTK systems. These include:

Increased accuracy: A PPK workflow can provide centimeter-level accuracy in your survey data, which is much more accurate than other drone surveying methods. This high level of accuracy is particularly useful for mapping large civil construction sites.

Improved efficiency: Using PPK can be much more efficient than traditional surveying methods, because it eliminates the need for manually laying out several ground control points, saving time and labor costs, particularly for large sites. For sites up to 100 acres, just one AeroPoint is needed for ground control when using PPK.

Greater versatility: Drone surveying with PPK can be used in a wide variety of environments, including remote or hard-to-reach areas, making it an ideal solution for mapping in challenging terrain that might jeopardize worker safety.

What are the advantages of GCP drone surveying?

Surveying with a drone and ground control points (GCPs) involves using targets with known coordinates to improve the accuracy of your survey data. Some advantages of surveying by this method over a manual process with a base and rover include:

Increased control: Using GCPs provides a greater level of control over the surveying process, as the locations and elevations of your targets are precisely known. This helps to minimize errors and ensure your aerial data is accurate and reliable.

Improved repeatability: GCP drone surveying helps ensure your surveys can be repeated with a high level of accuracy, especially if your worksite requires regular monitoring or up-to-date survey data.

Flexibility: Surveying with GPS can help to improve the accuracy of your data collected with the wide variety of drone types and sensors that are available, making it a flexible solution for many surveying applications.

Is PPK drone surveying right for my company?

Here are some factors to consider when deciding if PPK drone surveying is the right solution for you:

Accuracy requirements: PPK drone surveying can provide centimeter-level accuracy in surveying data. If your projects require high levels of accuracy, then a PPK workflow with a platform like Propeller can be a good fit.

Surveying environment: Using PPK does require access to a base station or network of smart ground control, like AeroPoints, for post-processing your survey data. If your worksite is such where a base station and/or network of AeroPoints can be used, then PPK drone surveying may be a good option for delivering accurate results.

Project budget: PPK drone surveying can be a cost-effective solution for surveying your worksite, as it reduces the time and labor when compared with traditional survey methods.

Survey frequency: If your surveying project requires regular site monitoring and the most up-to-date survey data, then PPK drone surveying may be a good fit for your company.

Is GCP drone surveying right for my company?

Here are some factors to consider when deciding whether GCP drone surveying is right for your operations:

- Similar to a PPK workflow GCPs can significantly improve the accuracy of your drone surveying data, which can be particularly useful for civil construction sites and quarry mapping.

- GCP surveying requires the placement of targets on the ground. So, if your site is in a location where ground-based targets can be easily placed and accessed, then GCP drone surveying may work well for your company’s needs.

- GCP drone surveying can also help ensure that the accuracy of your data can be repeated with a high level of accuracy, even if the survey is conducted at a later date (after initial ground control placement).