How Drones Help with Conflict Management in Construction

Anyone in construction will tell you how commonplace project conflicts are. With increasingly complex projects, specialized trades, and a more diverse presence of technology on the worksite, the possibility for miscommunication, and thus disputes between contractors and clients, is huge.

But the digitization of worksites, if handled properly, can help construction companies—as well as any other organization that handles earthwork—put an end to conflict altogether.

Drone data in particular is being used more and more as a tool for dispute resolution between parties and proactively safeguard against conflicts.

With the quality of drone technology available today, highly accurate topographical data can be collected more frequently, and at a lower price point. And more survey data means you can

- Execute designs with greater precision

- Track your progress (and the progress of subcontractors)

- Catch errors before they turn into disputes

- Maintain a record of your work to use as proof in project conflict management

Let’s explore how drone surveying functions as a conflict management tool in construction, and how drone data can be applied at every stage of a project.

Why is now the right time to use drones for conflict management?

First of all, let’s address why drones are having a moment in construction. The fact is, with recent drone hardware advancements and new post-processing workflows, drone tech is now at the point where using them to survey a site is a low-risk, high-reward investment.

Previously, surveying had to strike a balance between speed and accuracy. Either spend hours—or days—walking a site with cumbersome equipment, or settle for data with a less-than-ideal accuracy tolerance.

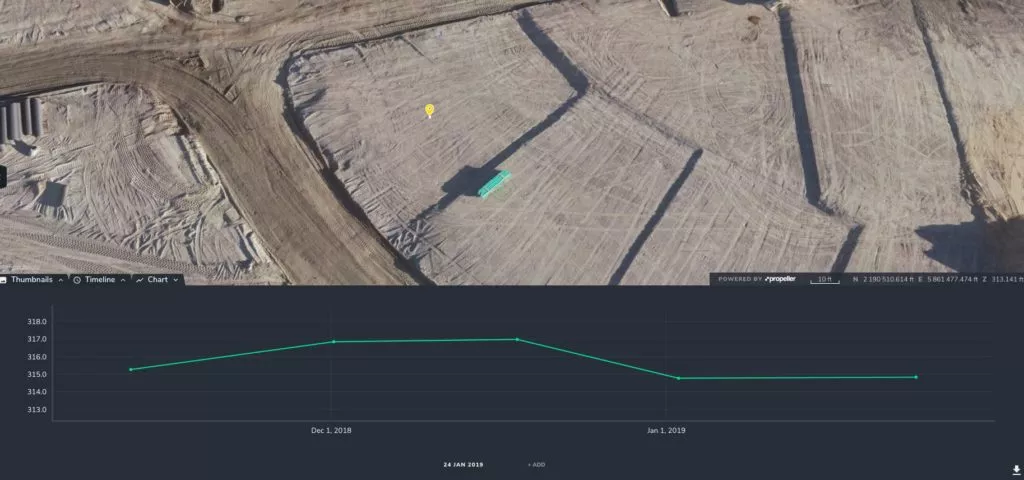

Because of the state of photogrammetric drone surveying, that’s simply no longer a battle that needs to be fought. And because of that, you can get actionable survey data more often. The frequency at which you get your data is only limited by how often you want to fly your drone.

That means more proactive planning, easier progress tracking—and more insights to help you avoid conflicts and mitigate ongoing disputes.

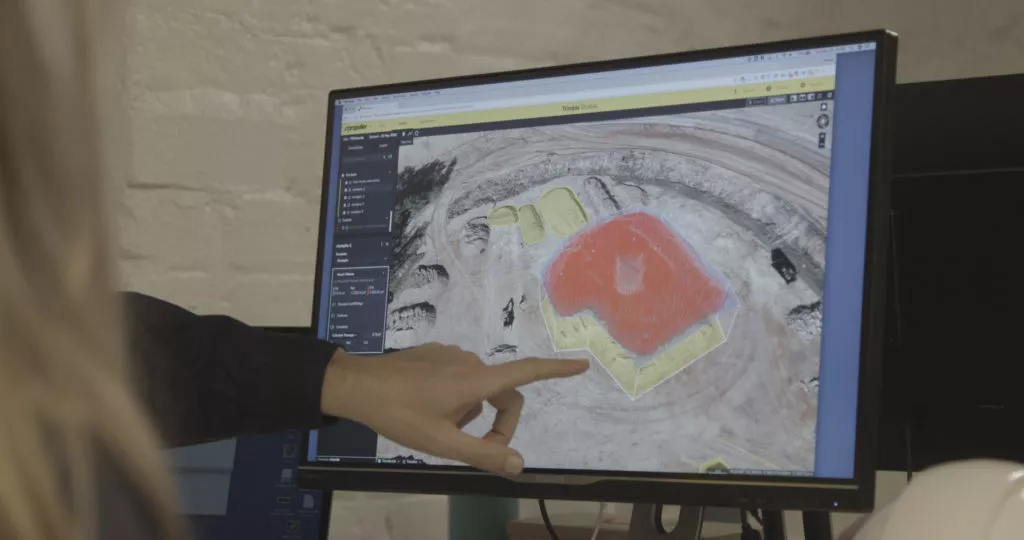

On top of that, the usability of drone data visualization software is improving all the time. If an estimator or manager with limited GIS/CAD software experience wants to pull data and generate a report, they can be taught to do so with limited effort.

When those in your organization whose job it is to manage conflicts are able to gather information for themselves instead of requesting it from a single platform user, they resolve issues faster.

Even if the data they uncover shows your organization was ultimately at fault in a conflict, being able to figure that out faster is hugely beneficial. The sooner you’re able to resolve a dispute, the sooner you can get your team back to work. Every minute a site stays halted because of project uncertainty, every minute your machines are powered down, you’re losing money.

A Case Study: The Journey From Simple Drone Surveys to Worksite Management (Part One)

Capturing initial state: Why you should be flying sites as soon as possible

At Propeller, we’re huge proponents of capturing the initial state of a project at the earliest opportunity. Having a survey of your topography before you move an inch of dirt is helpful for a number of reasons. Not only does it help with planning project logistics early on, it can also help you detect potential data discrepancies and opportunities for conflict before it’s too late.

In an ideal world, clients would supply you with only the most accurate site information. For a number of reasons, that’s often not the case. Maybe a previous contractor failed to accurately document their finished work. Or the client’s own survey of the site was performed poorly and produced inaccurate measurements. The site could even have sat dormant for months, its topo altered by wind and condensation since its last survey.

Whatever the reason, you never want to be left to the whims of another organization’s bad data.

With an initial, time-stamped site survey, if a client tries to blame you for conditions that existed before your team began working, you’ll be able to prove them wrong with a photorealistic 3D model generated from that survey.

Many disputes in earthwork projects stem from disagreements over how much material was actually moved. Let’s say a client’s plans underestimated how much dirt you’d had to move to get to their requested grade.

With a simple volume comparison between your initial and latest surveys, you can show them how much extra work you had to do, and hopefully get paid appropriately for it.

Flying a drone at the outset of the project means you’ll always have that initial surface information to refer back to.

The Value of Pre-Bid Drone Surveying

Many of our customers are already using drones to survey sites before they even bid on a project.

Often, walking a site pre-bid with a base and rover isn’t an option. If it’s an active site, doing so could be disruptive to operations. Or, the client simply might not feel comfortable letting you traverse around a risk-laden worksite.

The fact is, drones can get you critical pre-bid data that you otherwise wouldn’t have access to. That helps estimators choose projects more discriminately and calculate the cost of work more accurately.

It also means you can renegotiate the terms of a potential client’s proposal if your data doesn’t match up with theirs.

Take this potential scenario: You bid on a project that would require you to transport all the stockpiles in a given area. The proposal lists the area parameter AND the number of stockpiles therein. After the project starts, you realize there are actually more stockpiles within the project boundary than you were told. When you tell the client, instead of working to negotiate a solution, they choose to take advantage of the vagueness of the proposal language and make you responsible for moving that extra material.

Now, you may ultimately be able to prove through litigation that the miscommunication was their error. But why risk litigation? Even if you win, the cost of playing out this lawsuit is costly.

By performing a drone survey of the site yourself before committing to a project, you can iron out any inconsistencies in the proposal that might cause conflicts later on.

How drone surveys can help you avoid change order headaches

Change orders are the bane of any construction team’s existence. Whether it’s an adjustment to design, budget, or schedule, having to switch up operations to fit new plans is inconvenient at best, and costly at worst.

If you deem a client’s requested change order to be too costly on your end—or outside the agreed-upon scope of work—you may find yourself in conflict with them and your team at a standstill. As we’ve already said, you never want to keep your machines cold for too long.

With aerial survey data at your fingertips, being able to renegotiate a potentially problematic change order becomes much easier. Whether you have a recent enough survey to collect the information you need, or you have to fly your drone again after the change order comes in, you’re never more than 24 hours away from accurate drone data.

Once your site maps have been created, you just have to take the relevant measurements and generate a report to send to the client. You can even guide them through a 3D model of your site, taking advantage of the visual element to more clearly illustrate your issue with their change order.

There’s always the possibility that, even with drone data, you won’t be able to come to a compromise. In that case, your surveys can act as a powerful piece of evidence in your favor. With their degree of accuracy, drones are a more reliable means of measuring material than more traditional record-keeping methods, like truck counts.

With this regular progress data, you can ensure subcontractors stick to the scope of work—or prove that they didn’t if you need to.

Free webinar: Harnessing the Power of Propeller Hardware: AeroPoints, DirtMate, and More

Documenting the end of a project and proving your final work

Unfortunately, many conflicts arise during and after the completion phase. It’s during the project wrap-up that the project owner will compare your final work to the design—and any potential discrepancy between the two is an opportunity for conflict.

Upon completion of a project, you should make one final drone flight. That will act as your “as-built.” Basically, it’s your documentation of the site as you left it.

We’ve already talked about the benefits of documenting a site before you start a project, in case the topography has been affected by weather or other factors since its last survey. The same logic applies to documenting your work at the end of a project. If, months later, a client finds their site doesn’t match their expectations, you’ll want a way to prove you aren’t at fault for the discrepancy.

For contractors that primarily deal in earthwork, their work on a project will often coincide with the next contractor’s work. This makes drones particularly useful for capturing that final state. Instead of trying to use ground-based surveying methods on an active worksite, you can send your drone pilot out to survey the site without causing any disruption to operations.

Droney surveying can also help you prove that you left the topography in an appropriate condition, in case you need to prove so to environmental regulators. Proving that reclamation was handled appropriately is incredibly important in the mining and aggregates sector in particular.

Three other ways drone surveying helps avoid project disputes

Mobile maps – In addition to agreeing on design and scope of work, it’s a good idea to clarify beforehand how project changes will be communicated. You need to know both how you and project owners will communicate, as well as how you’ll relay those changes to your team in the field.

Crew is an add-on to the Propeller Platform that lets you share site maps with anyone on site through their mobile devices. You can even include relevant overlays like utility linework to help them avoid line strikes. If a utility strike happens, and you had access to the linework files, failing to communicate the locations to your field teams could leave you liable for the damages.

Processing reports – Drone data is useless if you don’t have a way to prove its accuracy. With a report documenting the quality of your aerial photos and ground control, you’ve got a piece of evidence that could come in handy if the legitimacy of your survey is questioned. Many of our customers already include processing reports in their regular updates to project owners.

Coordinate system ease – Let’s say a project owner supplies you with a site survey that includes published property boundaries. However, the data they get the boundary coordinates from was referenced through a different coordinate reference system (CRS) then their survey. Datasets using different CRSs simply won’t line up on the same map.

Make sure whatever software you use to process and visualize your drone surveys allows you to seamlessly perform CRS transformations, so you can work with disparate datasets and avoid digging where you don’t belong.

Ready to enter a conflict-free future? Let’s talk about starting up your first drone program.

Keep reading:

DHGI’s Survey Manager on Why Propeller is the Key to His Drone Program’s Success

Is Construction Software Worth the Cost? How (and Why) to Track Software ROI