How Do Contractors Use Their Drone Survey and Design Data?

As drone survey data becomes more and more accessible with cloud-based, easy-to-use earthworks site mapping and measuring solutions like the Propeller Platform, earthworks and civil construction professionals are finding it easier to estimate, plan, and manage their projects.

We’ll cover some of the most impactful ways contractors are putting their drone survey data to work in order to successfully manage their earthworks operations more efficiently. But before we dig in, here is a brief explanation of what drone surveying actually is and how point clouds and photogrammetry fit into the mix.

If you want to skip forward, here’s where we’re headed.

- What is drone surveying?

- What is Photogrammetry?

- Ways that contractors use their drone survey data

- Designs and Drone Data

- What Types of exportable data can drone surveying produce

- Propeller Platform Features

- How Propeller customers use their drone survey data

What is drone surveying?

To sum it up, drone surveying is really the next generation of job site surveying. Using a commercial-grade drone, contractors can capture survey-grade aerial images and meaningful terrain data for their worksites. The drone survey data is then processed and visualized into an interactive 3D map for progress tracking, volume measurements, and improved team collaboration.

By combining aerial images with onboard GPS via photogrammetry (which we’ll explain shortly), drone surveys create a digital “print” of a living worksite, which can be measured and updated over time, as the site changes.

What is photogrammetry?

Photogrammetry is the science of collecting geospatial information from 2D photos, often aerial images captured by drones. By combining enough overlapping images of the same features, photogrammetry software can then be used to generate photorealistic 3D representations of topographic surfaces.

Photogrammetry uses multiple views of the same feature, or a visually distinct point in an image, to triangulate its x, y, and z coordinates in space. The more features you match between images, the better you can relate images to each other and the terrain features within them.

Point clouds outline the shapes of features on a worksite, but to get a photorealistic digital surface model, you need to match those shapes with visuals. This is where image stitching, or ortho-rectification, “enters the picture.” The computer looks for common features shared by multiple images captured in the same location to fit images together and combine them with the point cloud.

Surveying and GIS professionals use drone photogrammetry, along with accurate GPS data, to create 3D maps and models for use in construction, waste management, mining, and aggregates operations.

Ways that contractors use their drone surveying data

There is so much you can do with the highly detailed data you get via drone surveying. Here are a few of the core ways earthworks professionals use the data they obtain by surveying with a drone and some tips for your business.

More accurately estimate earthwork volumes

Accurate estimates help ensure you are fairly compensated for the earth you move. By surveying the prospective job site with a drone, the data that contractors can review allows them to provide an estimate with pinpoint accuracy and increase their chances for winning the bid.

Balancing competitive estimates with productive operations requires knowledge and experience in earthworks, and in order to draft detailed bids, you need accurate data that comes from surveying your site with a drone. Using design-to-design measurement tools, estimators can better use their data to produce high-quality estimates and win more bids. Submitting an accurate bid before commencing work ensures that you aren’t moving more dirt than you need to and incurring extra, unplanned expenses.

Furthermore, using foresight and 3D models created from your drone data, you can mitigate risk and prepare for potential challenges you may face at each phase of construction.

TL;DR: Measure the volume of material required between design grades via drone surveying to ensure high accuracy and reliability in your material and project estimates.

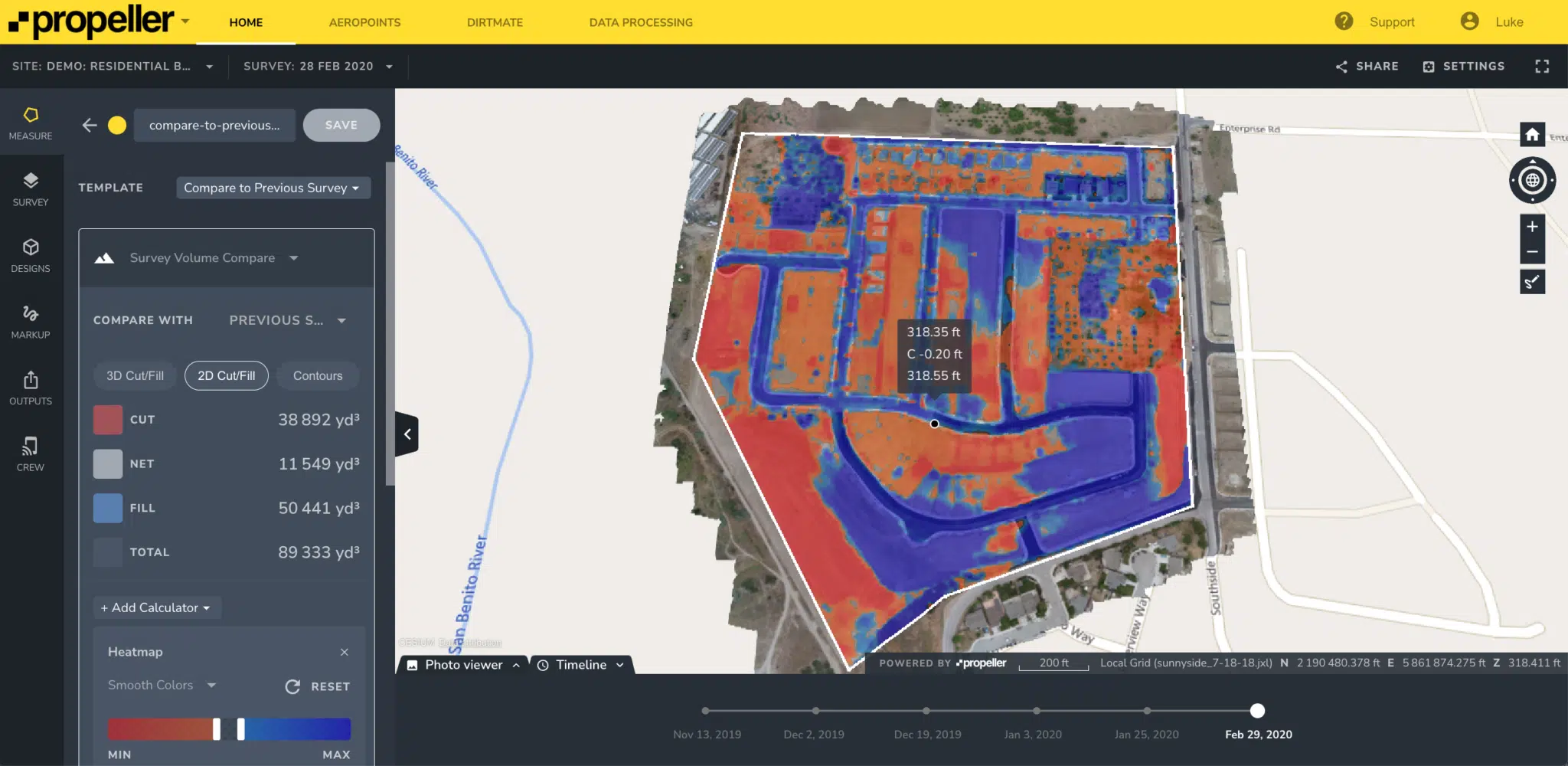

Calculate cut/fill volumes

After flying a drone over their sites, surveyors can use a photogrammetry software platform like Propeller to process their data and calculate cut and fill volumes for the current terrain against previous levels and also the project’s design surfaces. Once the measurements are complete, the information can be shared across the team and other relevant stakeholders. Data is downloadable in industry-standard file formats (including CSV, JPEG, GeoTIFF, DXF, and other files types) and in a wide range of coordinate reference systems.

DXF is short for Drawing Interchange Format or Drawing Exchange Format. It was developed by Autodesk to enable data interoperability between AutoCAD and other programs. A GeoTIFF is a metadata standard that embeds georeferencing information within a TIFF file. A CSV (comma-separated values) file is a text file in which information is separated by commas.

CSV files are most commonly found in spreadsheets and databases. Lastly, JPEGs are commonly used image files.

TL;DR: Survey your site with a drone regularly to obtain accurate cut/fill measurements that can be shared within your company and also with general contractors and other stakeholders.

Generate topographic contour maps

Contractors can generate customized surveys from their drone data processed with a software solution like Propeller. Using a tool such as a contours/heat map function, they can specify major and minor intervals on their job site, and a range of data sharing options allows effective collaboration among project teams and other stakeholders. Contour maps can be viewed within the software platform or be exported as PDF files or (for standard contours) as DXF files.

TL;DR: Create more customized contour maps of your worksite terrain by employing a drone surveying program.

Terrain filtering

A digital terrain model (DTM) represents just the bare earth surface and does not include structures or other above-ground features. These models are generally used for applications such as analyzing the slope and aspect of the terrain, or for creating contour lines to represent the topography on a map.

Drone surveying solutions allow you to filter obstructions from your data to create clearer, more readable surveys. Scrubbing objects like vehicles and vegetation from a DTM helps with asset monitoring and tracking job progress. It’s also critical for accurate volume calculations.

Whether it’s a hedge stopping a bare-earth calculation or a vehicle parked on an active surface you need to get a grade on, Propeller’s terrain filtering algorithm helps minimize these obstructions when moving dirt on your site.

TL;DR: Create clearer, more accurate surveys by removing obstructions from your drone survey data using terrain filtering.

Project progress tracking against designs and stockpile volume measurements

Regularly checking the progress on your construction or earthworks site against design is key to keeping your project on track, but it’s difficult to generate those comparisons quickly with traditional surveying methods.

With drone surveying software, uploaded design surfaces can be viewed at any time against any survey captured for that site. This removes the conversation barriers that arise when using drawings or mere visual inspections to gauge progress against designs.

Even the best designs are only as good as your team’s ability to interpret and implement them. Accurate design-to-design comparison tools within a drone surveying software solution like Propeller enable you to better plan work and measure progress, beginning with pre-bid measurements and progressing to final grade completion.

Furthermore, performing complex volume comparisons against other surveys and design files is incredibly quick and easy with drone surveying software solutions like Propeller. All volume measurements are instantly visualized in 3D, so that anyone can understand what’s been measured and visually track volume changes.

TL;DR: By comparing your current stockpile volume either against original design or past surveys, you’ll have accurate measurements at your fingertips and avoid “moving dirt twice.”

Prepare pay applications

The payment system in the civil construction and earthworks industries differs because of the number of supplies used, contractors working on a single project and the complexity of billing, from labor to equipment and raw materials. A complete application for payment is needed that’s more detailed and lengthy than a standard invoice. Pay applications include documentation that proves construction or excavation work took place, and they confirm that the billed amount is correct and fair for all stakeholders.

TL;DR: Photo documentation accurately demonstrates evidence of work completed and material delivered. Companies can use their drone survey 3D images of the job site to show their work is complete and, when needed, identify site conditions and reduce hazardous risks.

Reduce errors

Accurate data makes for successful projects. With frequent high-accuracy drone surveys, you can reduce the margin of error on your worksite, helping to prevent change orders and avoid costly rework.

Rework costs can negatively impact your bottom line with poor project management decisions due to unreliable data to blame for a significant amount of avoidable rework.

TL;DR: Avoid rework by using accurate 3D site surveys that make it easy to keep track of progress and compare it to what’s happening on site with data you can trust. Drone technology has developed to the point where drone surveys are accurate to 1/10 foot (3 cm).

Improve team collaboration

Clear communication is essential to the success of any project. The best drone surveying software solutions, like Propeller, offer cloud-based, easy access to real-time data for anyone who needs it. Data silos can’t be eliminated without readily available access for everyone.

Establishing a single source of truth is one of the best ways to resolve disputes—and even prevent them. Miscommunications are greatly reduced when everyone is reviewing the same, easy-to-read 3D map and measurements of a job site.

TL;DR: Establish transparent communication across the project team and make sure all stakeholders involved have access to the data they need to keep operations moving smoothly.

Designs and Drone Data

Propeller’s drone surveying software solution provides earthworks professionals with the ability to quickly and easily import their design files in TTM or DXF formats and view them in 3D, even using a local site coordinate reference system. Here’s how you can use these formats with the platform for high quality drone data and design integration.

Importing TTM files

A Trimble Terrain Model (TTM) file is a file containing a model of the surface. TTM files can be imported to the Propeller Platform as a design. Once imported, you can open the TTM surface and visualize it in relation to your jobsite terrain by creating surface-to-design volume measurements between the TTM and your drone-captured terrain. You can also export a specific area of your site from Propeller as a TTM surface.

Importing DXF files

Your site’s terrain can also be represented as a DXF file and imported into Propeller in the same manner as a TTM. Additionally, DXF supports the following features in the platform to help customize, visualize, and compare your site against design:

- Removing or renaming individual layers of the site

- Clamping linework to the ground

- Measuring from line work vertices

Once you’ve imported your DXF or TTM files into Propeller, there are many types of exportable data and also valuable platform features available for you to use in your workflow. Read on to learn more about both of these.

What types of exportable data can drone surveying produce?

Drone surveying platforms can generate a variety of exportable data that earthworks companies use to manage their projects. Here, we’ll examine some of the types that can be exported from drone surveying software, like Propeller, and then used in other parts of an earthmoving company’s workflow.

Orthophotos

An orthophoto is a geometrically corrected image with uniform scale that follows a given map projection. It can be used to measure true distance, because of its accurate representation of the Earth’s surface, having been adjusted for topographic relief, lens distortion, and camera tilt. The key difference between a normal aerial photo and an orthophoto is the perspective and accuracy. A normal aerial photo has a perspective view. You can see the sides of buildings and other objects, and the perspective changes depending on where the photo was taken.

By combining many small images, you’re able to create a large, map-quality image with high detail and resolution, which earthworks companies can use to measure progress on their job sites.

A platform like Propeller provides the ability for earthworks companies to easily export an orthophoto from any polygon measurement across regular and composite surveys, meaning stakeholders can carry out further work using the data they captured from drone surveying. Large earthworks sites will benefit from this feature as they can quickly and easily create orthophotos and export a particular area of their site, and continue additional steps in their workflow in high resolution.

Recently, Propeller has updated outputs from the tiles in our platform. These updates include the ability to:

- Export orthophotos from composite surveys

- Export orthophotos from within a measurement

- Choose the resolution of orthophoto

Point clouds

Point clouds are a collection of millions of points with very specific coordinates that indicate exactly where each point belongs in space. They are used to measure an object’s depth, elevation, shape, and exact geolocation. Every point cloud is essentially a data-based representation of a physical space, so each one is as unique as the terrain it’s being used to measure.

Today, drone surveying has made 3D point clouds more accessible and easier to use than ever before. Historically, GIS specialists, engineers, and surveyors created point clouds using pulses of laser light (LIDAR). Instruments measured the time it took for a beam of light to bounce back from an object on the ground to the sensor, providing readings on that object’s height, width, and depth. Over time, collection mechanisms expanded to include UAVs and drone photogrammetry.

A successful earthworks project depends on consistently obtaining accurate and up-to-date information in front of the right stakeholders. Drone survey software like Propeller allows you to easily export point clouds. They are especially useful for calculating volumes because the points comprise horizontal and vertical spatial data.

Terrain mesh

A terrain mesh is a collection of points that represent a continuous surface. Usually connected into triangles, it forms a shape within a three-dimensional space. Terrain meshes can also include image textures mapped onto the surface for reference and are typically used for high-precision modelings, as they can be used for calculations of surface area and volume.

Generated from your drone survey data, a terrain mesh can be exported from a software platform like Propeller and be very helpful in mapping highly variable surfaces and representing how those surfaces change throughout the course of an earthworks project. It can also help to evaluate terrain usability for steeper slopes, spot a survey error, and prepare for future site work.

Other forms of exportable data

Accurate reports generated from a drone surveying software solution like the Propeller Platform help earthworks and construction companies plan their projects, track material inventories, and monitor progress. Within the platform, teams can choose from many reports to export data that gives project foreman and supervisors a better understanding of their site’s condition including:

- Materials Stock Sheet & Aggregated Material Reports

- Inventory Report for Stockpiles

- How to Export Measurements as a PDF or CSV

- How to Export a PDF Map of Your Site

You can also compare your drone survey cut/fill data against your design by generating a take off report within the platform. This provides you with accurate cut and fill quantities, and shows you exactly how close you are to balancing the site. From there, you can develop a plan that keeps you on schedule and on budget because you’ll be able to clearly understand your site details. Furthermore, you’ll have the ability to grant access to clients, contractors, or any other stakeholders who need to review the takeoff reporting.

Propeller Platform Features

The following are features currently available in Propeller’s drone surveying software solution that earthworks project managers, among other roles in earthworks and civil construction companies, use to obtain knowledge about how their worksites are progressing.

PDF overlay

To help you easily visualize the work to be done across your site and track progress, Propeller offers you the ability to overlay PDF design files on top of your drone surveys within the Platform. This allows you to make better decisions, quicker and with fewer errors.

Consistent site monitoring is the best way earthworks contractors can determine whether work is progressing according to plan and within the budget. This feature is particularly helpful for project managers, superintendents, foremen, and engineers who regularly review PDF design files as construction projects progress. Often, these design files act as “the contractual source of truth” for a project. PDF Overlay also helps companies share the project status with larger teams and project stakeholders, providing them with confidence that work is on track.

Feature highlights:

- Overlay PDF designs on top of your latest drone surveys so you can visualize build progress and the future state of the site against current conditions

- Quickly spot conflicts between what’s designed and what’s been constructed

- View drone surveys and PDF designs in one place to simplify project planning and communication

- Easily add up to three geo-reference points to ensure drone surveys and PDF designs are aligned

- Adjust the transparency of the PDF so you can easily compare the design against the drone surveyed terrain underneath. You can also crop the PDF to remove any unnecessary details and refine your map.

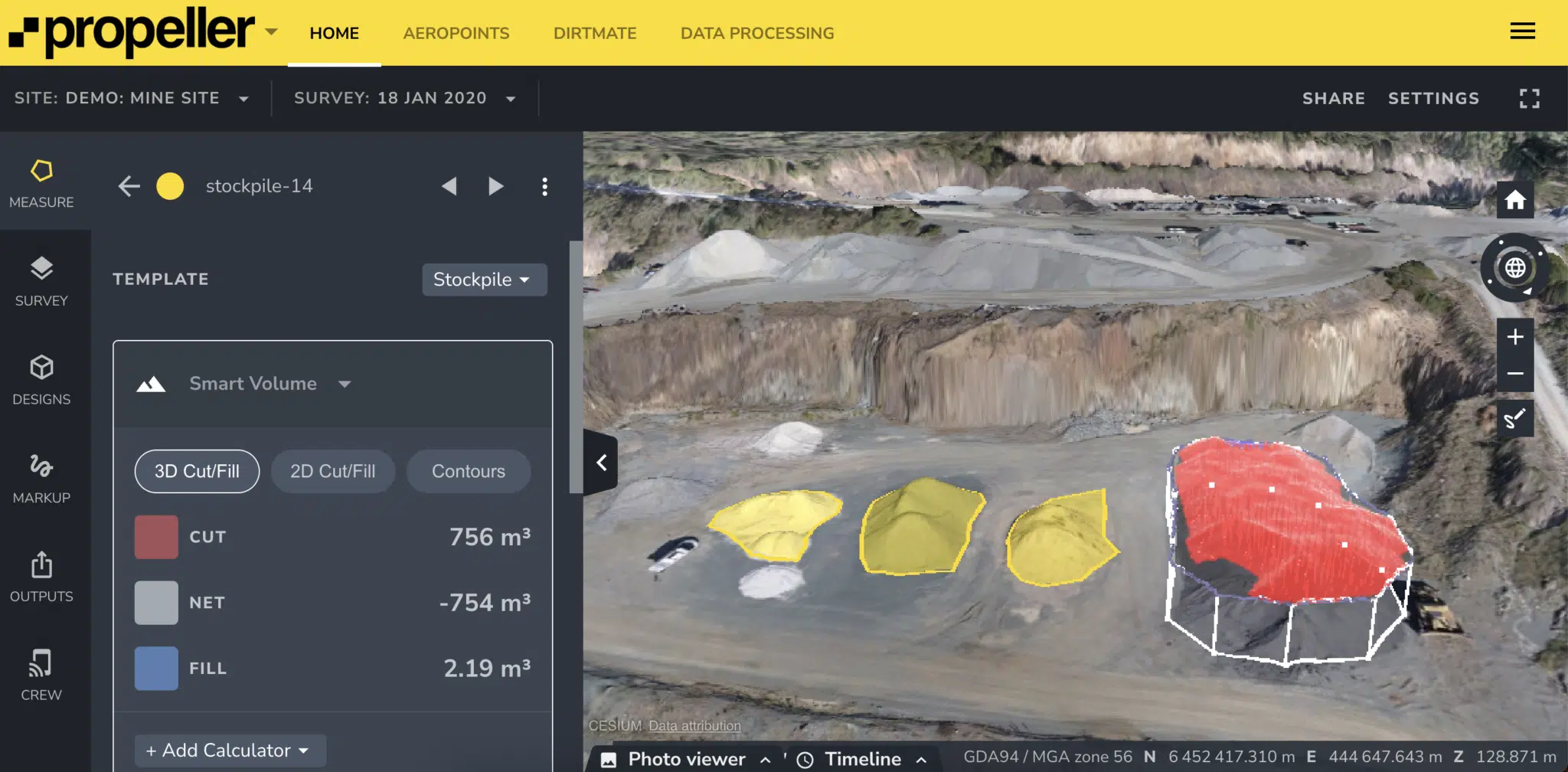

Stockpile report

With customizable inventory reports for stockpiles, you can give everyone—from production supervisors on site to auditors in the head office— the data they need to make mission-critical decisions faster.

Inventory reporting for stockpiles lets Propeller Platform users generate PDFs and CSVs with only the information they want to include. More control and flexibility in what gets included means users can generate reports more specific to individual workers’ needs.

Mine and quarry managers use stockpile reports to communicate how much stock they have and how much has been moved since the previous survey. This information is critical for financial forecasting, resource planning, and supply chain management. All require reliable, accurate stockpile data to be done effectively.

Propeller’s inventory reporting for stockpiles makes it easy for everyone in the organization to get the data they need. Anyone—not just surveying and GIS professionals—can jump into the platform and generate a report. When you don’t have to rely on a single user with specialized platform training to pull inventory data, you can get everything else done faster.

With accurate, dependable stockpile volumes at their fingertips, financial record keepers are better able to reconcile actual and reported quantities of material when it comes time for an audit. Propeller’s new report for stockpiles simplifies the reconciliation process by making it possible to package the data in a more digestible, usable format.

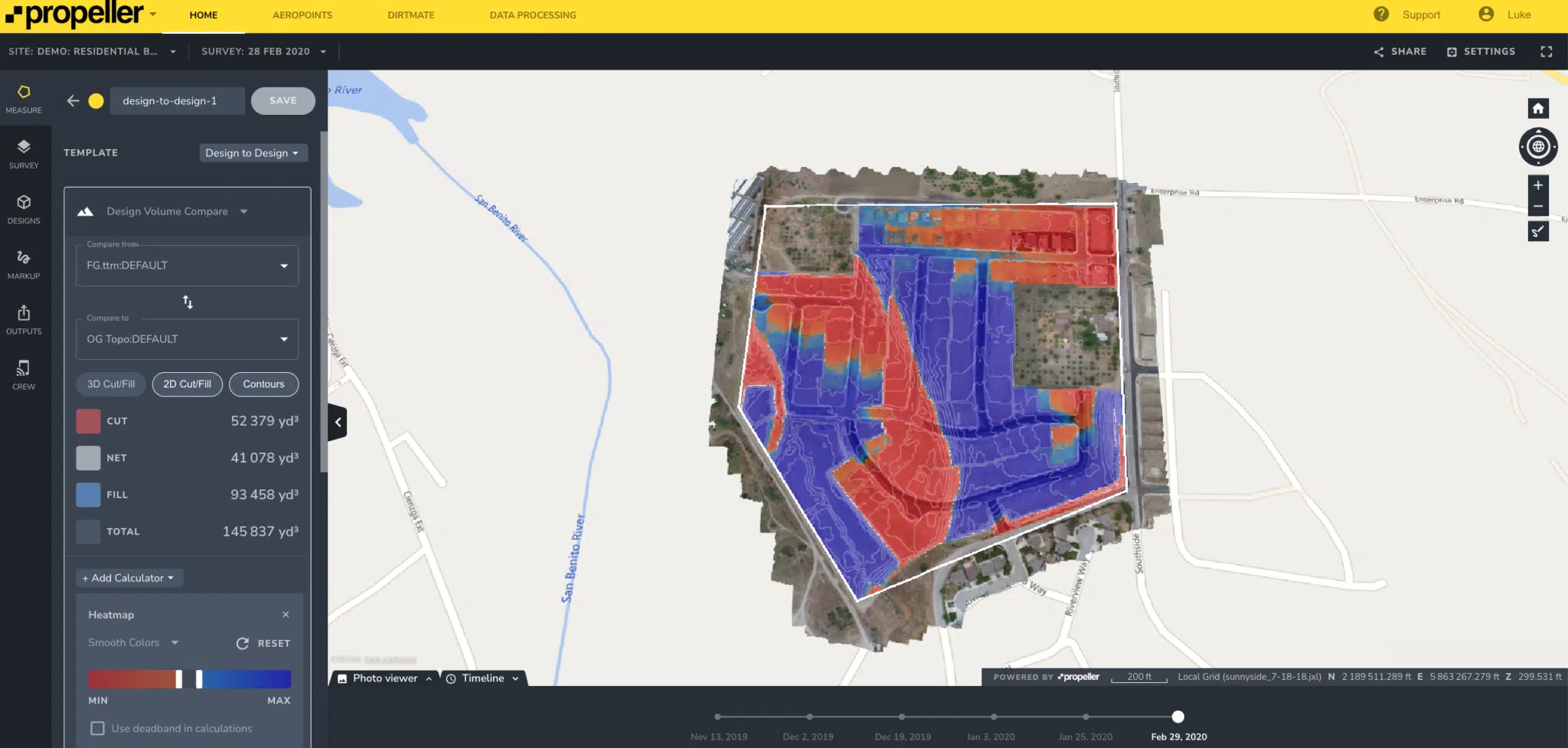

Design-to-design comparison

This feature allows users to calculate volumes or differences between two different design surfaces (like a subgrade surface to the finish grade surface).

When bidding a project, carefully balancing competitive estimates with profitability can be difficult. You need accurate data to win bids, and you need to be able to collect it yourself. By using the Design-to-Design measurement tool, estimators can better use their data to produce high-quality, competitive submissions—and win more bids.

This feature enhances project oversight and visibility with easy access to comparison data through the Propeller Platform. With this valuable information, you’ll be able to make better decisions and manage change orders more effectively throughout the course of the project, resulting in fewer cost overruns.

Here are ways you can quickly compare design files and accurately measure volumes across your site:

- Deliver accurate estimates: Measure the volume of material required between design grades to ensure high accuracy and reliability in material and project estimates.

- Track progress from pre-bid to final grade: Compare original ground files with updated designs throughout the project to accurately track progress and proactively address variances or other issues quickly.

- Increase flexibility in project planning: Manage design changes and avoid cost overruns by gaining greater insight into material volumes and adjusting plans, cost estimates, and material orders on the fly.

Take off reports

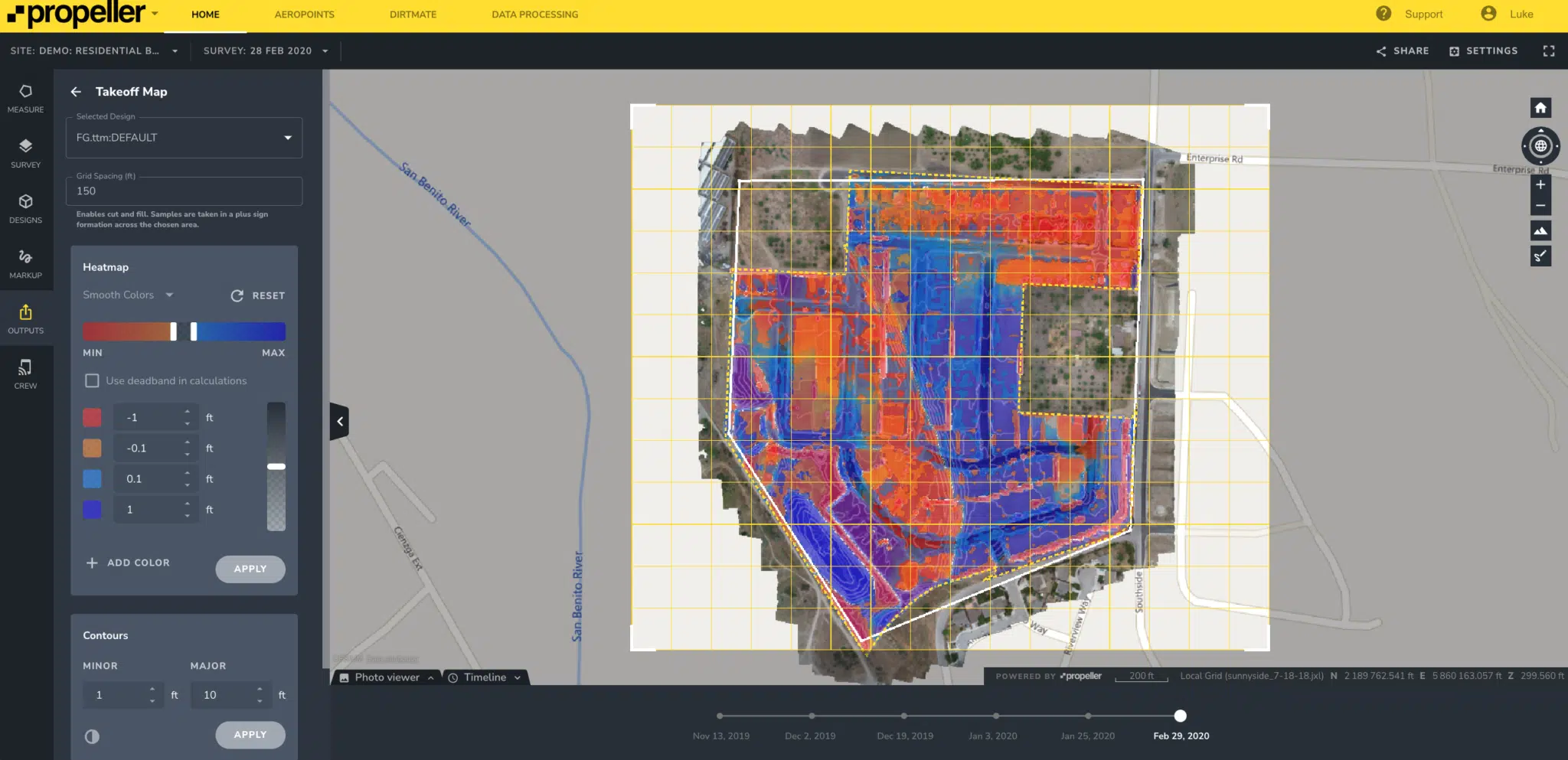

Quality earthwork takeoff reports provide an easy-to-read, accurate summary of the difference between your project design and the existing cut/fill conditions of the worksite. Project managers can view a high level of detail and have more flexibility with the ability to further customize worksite maps. You can view your map either on screen or via a PDF file up to size A0.

Here’s a look at how Propeller can provide your business with more detailed maps:

- Grid and page orientation: You can customize grid spacing and positioning to ensure your grid layout fits your entire worksite map. With the ability to rotate your map to any angle, you can change your design model’s orientation at the top of the drawing area to either project north or true north. Project north is based on the predominant axis of the structure or building geometry, and it affects how you create views of the site. True north is the real-world north direction based on site location. With this orientation flexibility, you can represent your site conditions more accurately.

- Heat map grading: Efficiency and clarity are vital on a worksite, so knowing exactly what volume of cut/fill is required in each section of your map is important. The heat map grading helps you more accurately understand how your cut/fill volumes have changed by allowing you to assign different colors based on the cut/fill amounts required for the project. Using these clear visual indicators on your sitemap aids in project planning and makes communication with your team and other project stakeholders easier.

- Contour lines: Propeller’s contour line functionality helps to better display the different granularity between the minor and major contours of your site. Being able to clearly draw and visualize the cut/fill requirements means your map is easier to interpret and understand for all project stakeholders when reviewing on screen or within a PDF file.

Hydrology tracking

Hydrology provides you with an easy way to quickly visualize or forecast how heavy rainfall or other flowing water could affect your worksite, based on the current topography and terrain. The feature includes two options: Flow Lines and Liquid Drop Analysis:

Flow Lines –This function displays lines across your site showing how significant rainwater or other water streams could flow across the terrain. It can also highlight where you could see significant high water flows, as well as where standing water could collect. Within the platform you can navigate across your site and select the specific area you want to analyze for water flow.

Liquid Drop Analysis – This function focuses on a specific area of your site. You outline the radius of the spill/flow you want to view, and click on the map to start the simulation of the water flow. You can review the simulation as many times as needed and can also adjust the radius size of the area you want to analyze.

How Propeller customers use their drone survey data

We’d like for you to read what some real earthworks companies that employ drone surveying programs have to say. Below are just a few examples of how our customers are using their survey data to advance their businesses.

Rickabaugh Construction

Rickabaugh Principal, Marc Rickabaugh shares how valuable adopting Propeller has been for their company. Read full case study.

“Before Propeller, we had our projects flown a couple times a year for drone photography, but we did not utilize mapping. We used to gather all of our topographic information manually, which was very time consuming and costly. Now, the regular mapping of our commercial and residential infrastructure projects with Propeller provides us with valuable earthwork progress tracking data and stockpile volume management.”

R&K Excavation

Patrick Shultz explains how R&K uses Propeller for a complex road project. Read full case study.

“The earthwork for this road build project is split, with R&K managing half of the site and the general contractor, Better by Design (BBD), overseeing the other. R&K is helping BBD with their surveys, as well. We’re surveying the site weekly and using Propeller to generate a weekly progress report. For example, if we worked in sections 2, 3, and 7, we can show Better by Design what material we moved and our cut/fills for each area. We have our grade control files loaded in the platform so we can see how much farther we have to go. It really keeps us on track, because not everyone can be on site with a rover in their hands.”

Ledcor

Luiz Araujo points out that they use their drone data from Propeller for project planning, as well. Read full case study.

“For someone who has never used a drone, they may be scared of accuracy. But I can tell you the accuracy from Propeller is great. With a drone you can capture way more detail than field surveyors can using GPS or base stations. It definitely will be a lot faster for you, and it’s not only for surveying and engineering, but also for project coordinating and planning the worksite. Having that wide, ortho image of the construction site really helps with planning logistics, where to place equipment, and where to put stockpiles. It’s user friendly, and you don’t need decades of experience to operate the platform. I am happy with the system and would definitely implement it into future projects I work on.”

Tezak Heavy Equipment

Kyndra Tezak shares how her company uses the Propeller Platform with their survey-grade drone to provide real-time data to their quarry and project crews, and also other project stakeholders. Read full case study.

“The data we collect allows our team to:

- confirm project boundaries

- produce precise inventory reports

- provide job progress tracking to look at productivity levels and billable quantities

- provide cut and fill volume reports from flight to flight

- create 3D models of the project site per flight

- compare the project CAD design files to individual flights to see how the project is aligning.”

Edgerton Contractors

Jeremy Craven explains how he used the PDF Overlay feature on one of their projects and found it to be a valuable part of the Propeller Platform. Read full case study.

“Edgerton recently won a project on a site impacted by previous industrial users. While many of the previous buildings were demolished, much of the subsurface infrastructure remained, and we were constantly uncovering unknown pipes, etc. The property owner had historical maps only available in PDF format. Now, using the Propeller PDF Overlay tool, I can bring these files straight into the Platform and visually georeference the drawings with our aerial survey maps to better manage our work.”

As you can see, the data you obtain from surveying with a drone can be used in many ways to enhance your business and improve your customer and project team communication. This can lead you to more successful projects!