How Coordinate Reference Systems and Ground Control Can Deliver Survey-grade Accuracy

The use of drones for surveying earthworks and civil construction sites continues to rise as the technology becomes easier to use and more affordable. Therefore, understanding topics like coordinate reference systems, land surveying vs. construction surveying, and ground control is becoming more important for teams responsible for managing site work. We’ll explain what coordinate reference systems and ground control are, and how you can use these tools along with Propeller hardware and software to gain survey-grade accuracy when managing your site. You’ll learn that it’s a fairly straightforward process that, with a little training, any earthworks pro can master.

Here are the topics we’ll be covering, in case you want to skip ahead.

What are coordinate reference systems?

- How coordinate reference systems work

- How coordinate reference systems can make surveying more accurate

Land surveying and construction surveying, and how they differ

What is the role of ground control in drone surveying?

AeroPoints, Propeller’s smart ground control

- Propeller Corrections Network

- How to use AeroPoints for ground control

- Different ways to use Aeropoints

- Commonly asked questions about AeroPoints and ground control

How to Process Drone and Ground Control Data After Surveying

- What is photogrammetry?

- How real-time kinematic (RTK) processing works

- How post processing kinematic (PPK) works

- Why drone surveyors prefer PPK

How are earthworks companies using AeroPoints for ground control to achieve survey-grade accuracy?

What are coordinate reference systems

Whether onsite or in the office, if you use survey data to map and measure your earthworks or civil construction jobsite, you may have had to answer the question, “What coordinate system are you using?” A coordinate reference system (CRS), sometimes referred to as a spatial reference system, is a series of mathematical rules that define the location of a point or feature in an established space. More specifically, a CRS defines how a two-dimensional, projected map is related to real locations on the earth. The reason many coordinate systems exist is to ensure accuracy around the world. Due to the uneven sphere of the earth and shifting continents, a single coordinate system doesn’t work for producing accurate maps.

Published coordinate systems are based on specific global or local guidelines. Most major GPS survey equipment is loaded with a published coordinate system, and it’s important to understand which system is the most suitable for the location where you are working. However, if you’re surveying a smaller jobsite, you could choose not to use a published CRS altogether and use your own arbitrary coordinate reference system or a local grid.

Understanding the what, why, and how of coordinate reference systems is just the beginning. The next step is to put that knowledge into practice to not only create an accurate and reliable site survey, but also better understand the site data you use on a daily basis.

How coordinate reference systems work

Technically, there are two classes of coordinate reference systems: geographic and projected coordinate systems.

Geographic coordinate systems are three-dimensional grids. These spherical or ellipsoidal systems are generally used for measuring and communicating positions directly on Earth in the form of latitude and longitude. Although longitude and latitude can locate exact positions on the surface of the globe, they are not uniform units of measure.

Mathematical formulas are used to convert a three-dimensional geographic coordinate system to a two-dimensional, flat projected coordinate system. This conversion is known as a map projection. While based on a spherical geographic coordinate system, projected coordinate systems use linear units of measure for coordinates, so that distance calculations can easily be made in terms of those same units. Latitude and longitude coordinates are converted to x, y coordinates on the flat projection.

Projected coordinate systems can be more useful for worksites over geographic coordinate systems because they have less local distortion. For example, a local grid can be as small as the size of a single site, which reduces projection distortion considerably. Distortion happens within an angle, area, direction, or distance because it’s impossible to completely flatten a spherical surface (like the Earth’s terrain).

How coordinate reference systems make surveying more accurate

Using the appropriate coordinate reference system can enhance the accuracy of site surveys because they provide a context to all quantities mapped on site—for example, road lengths, stockpile volumes, cut/fill quantities, road grades, berm heights, and pit depths. Without a known coordinate reference system, it’s really not possible to produce a readable survey because geographic features on the site survey would not line up properly.

Land surveying and construction surveying, and how they differ

Here, we’ll explain the fundamentals of land surveying and construction surveying and how they are used.

Land surveying and GIS

Land surveying and geographic information systems, better known simply as GIS, are often compared. But what are they and how are they used? GIS is a technology system for capturing, storing, checking, and displaying data related to positions on the Earth’s surface. It can be used for analyzing potential new development projects, visualizing open space areas, or even creating maps for the internet.

Land surveying is used to establish property boundaries by recording precise measurements using GPS equipment, levels and other specialized equipment. Land surveyors are licensed and conduct certified surveys that can legally re-establish and mark existing property boundaries or consolidate two or more parcels of land, among other use cases. The data gathered by a land surveyor can also be used to settle property disputes or be used by a general contractor preparing a customer’s site for construction or excavation.

Both GIS and land surveying are precise, but for different purposes. Land surveying is a bit less accurate at measuring the horizontal coordinates of topographical features, but very accurate when placing this feature in relation to other locations. Conversely, GIS provides the precise measurements and location of individual topographical features on a site, but is less precise at determining the relative position of those features to each other.

Construction surveying

While construction surveying is similar to land surveying, it differs in that the surveyors read and analyze data to stake out worksites for bridges, roads, or other earthworks operations to ensure the project can be completed according to design. This work can be done via a traditional method using a base and rover and walking the site, or it can be done by surveying with a drone and processing the aerial images of the site using photogrammetry (we’ll cover more on this later). Construction surveyors also map active sites during projects to monitor progress and ensure work remains on track. When surveying with a drone they also employ ground control.

What is ground control in drone surveying

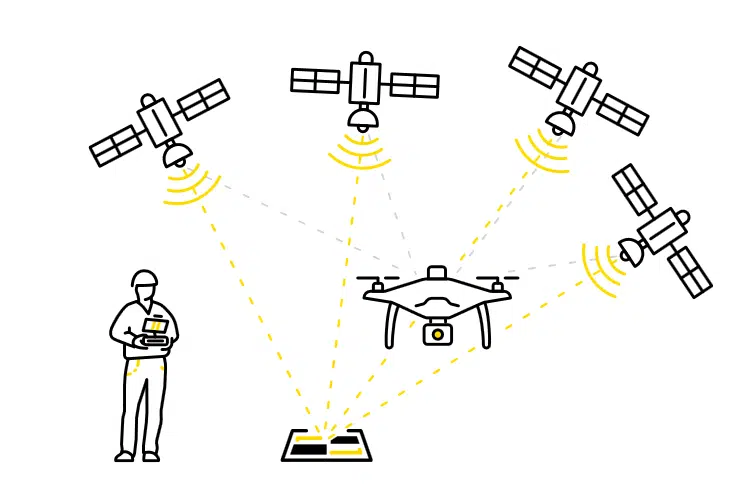

Ground control is one of the most important elements of a drone surveying construction or earthworks project because it ensures accuracy. RTK- or PPK-enabled (more on this later) drones are designed to capture high quality images from the air, but their accuracy does not automatically translate to accuracy on solid ground.

In drone surveying, ground control points (or GCPs) are points on the ground with known coordinates that a surveyor can precisely pinpoint. With these you’re able to accurately map large areas with a drone. Essentially, GCPs reduce the margin of error from a scale of meters to centimeters.

How to properly place your ground control points

Ground control is like pinning down the whole survey of your site as a tarp is laid over an object and held down with weights. If you don’t have weights (GCPs) evenly spaced around the edge, the entire tarp can become bunched up or distorted. You also need a few weights in the middle to hold the tarp snug and flat, so no part slips off or is pulled up by the wind.

Once you have identified the appropriate coordinate system and set up your GCPs, you’re now ready to collect survey data. Learn more about the best practices for ground control placement.

How ground control differs from survey checkpoints

To obtain survey-grade accuracy when mapping your work site, proper ground control, whether “smart” or traditional, is essential. Traditional ground control requires manually walking the site and marking the ground with known points. “Smart” GCPs (like Propeller’s AeroPoints, which we’ll discuss next) offer an efficient alternative to traditional ground control because they use detected GPS data to provide survey-grade accuracy without the need to manually mark and measure locations using a base and rover.

Survey checkpoints are points with known coordinates that are used to validate the accuracy of the survey. They are shot using the same methods as GCPs, but with one key difference: GCPs are used to correct the model and adjust image coordinates, if necessary. Survey checkpoints are used as additional reference points to validate the model and provide the entire crew with confidence in its ongoing accuracy. Unlike GCPs, checkpoints do not affect how the survey is processed in any way.

AeroPoints, Propeller’s smart ground control

Aeropoints are Propeller’s “smart” ground control points that deliver precise positional data just like traditional surveying methods, but quicker and more affordably. They are known as smart ground control because of their 2-in-1 design: each AeroPoint contains a built-in GPS receiver that allows it to receive positional data that can be used later for PPK corrections (which we’ll explain later), while the checkered design means it serves as a highly visible ground control point. Surveyors don’t have to measure and mark locations using a base and rover when they use AeroPoints, which saves time and money.

AeroPoints are also highly flexible and can be used as checkpoints, or even base stations, and are designed for heavy usage in a variety of environments with any surveying drone and any software.

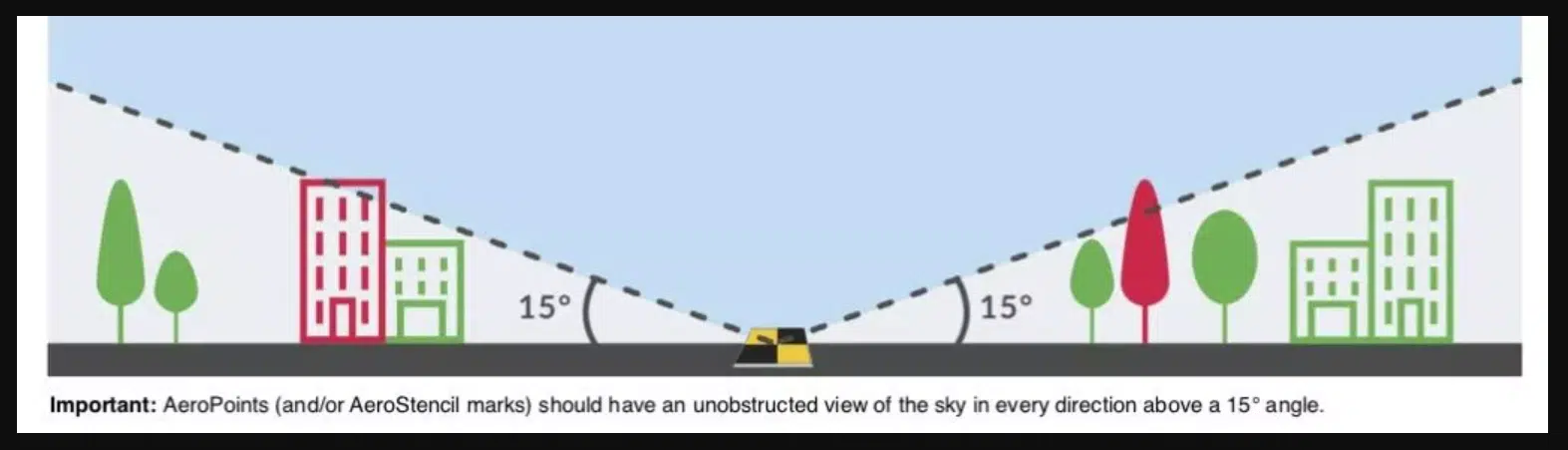

When planning AeroPoint placement, look for possible line-of-sight obstructions. Avoid placing them under trees, near fences, or any other obstacles. Doing so could interfere with their communication with GPS satellites. AeroPoints should have an unrestricted view of the sky in every direction above a 15 degree angle.

Once you have identified the appropriate coordinate system and set up your GCPs, you’re now ready to collect survey data. Learn more about the best practices for ground control placement.

Propeller Corrections Network

The Propeller Corrections Network (PCN) integrates base stations worldwide and manages sourcing and uploading RINEX (Receiver Independent Exchange) files for you. RINEX is a data interchange format for raw satellite navigation system data. Using satellite observations from a base station near your survey site, the PCN ensures your AeroPoints data can be processed and corrected automatically. This process ensures you receive the most accurate survey data possible.

How to use AeroPoints for ground control

You can complete a drone survey using AeroPoints as your ground control in just a few simple, efficient steps:

- Place your AeroPoint on the ground nearby and turn it on

- Initiate your pre-programmed drone flight, and fly your site for at least 10 minutes…that’s all it takes

- Connect to a wifi network to upload your aerial survey data

The Propeller Platform then handles the data processing for you, so you’ll get a complete and accurate data set back as soon as 24 hours from your flight—no manual processing needed. After that, you’ll have a 3D map of your worksite, stockpile volume measurements, and everything else you need to make informed decisions about your earthworks project and share that data with your stakeholders and project teams.

Different ways to use AeroPoints

Here are different ways you can use your AeroPoints, whether you’re inside or outside the Propeller Corrections Network or not. For each method there are different logging and placement requirements that are outlined below.

1. Fully Automated Processing In Propeller Corrections Network Coverage Areas

Automated processing is the simplest way to use AeroPoints on your site. It ensures a standard 24-hour turnaround time, and preserves the efficiency benefits that these smart GCPs provide on your drone survey. If you’re within the Network, choose the Propeller Corrections Network during your dataset upload. You do not have to send us supporting data or spreadsheets.

2. Using an AeroPoint as a Base Station on a Known Point

You might also be working on a site with its own calibration. In the case of local coordinates, we recommend using your AeroPoint on a known mark.

Simply place an AeroPoint on a known survey mark or benchmark location in your survey area. Be sure to place this AeroPoint first, and pick it up last. This allows it to record data for the duration of your flight. Propeller uses this AeroPoint, combined with the known coordinates of the benchmark location, as the reference point for the other AeroPoints used in the survey. Learn how to process AeroPoint data using a known point.

3. Using an AeroPoint to Create a New Known Point

If you don’t have the option of using the Propeller Corrections Network or known marks aren’t available, the global accuracy of your survey will be reduced. But you can still use AeroPoints to get results that are internally accurate and consistent over time.

To use this method: Find a hard, flat surface that won’t move or be disturbed, and establish your own “mark.” (We recommend using heavy-duty spray paint like that used for line-marking.) Place one AeroPoint at this mark and ensure it is left in place to record at least two hours of data.

For your first drone survey, we’ll use the data from this AeroPoint to calculate an estimated point. Then when you fly your site again, we’ll treat that coordinate as a “known mark.”

4. Using Your Own RINEX Corrections

Should you have access to a dual frequency L1/L2 RTK rover or your site has an RTK base station receiver, Propeller allows you to provide RINEX formatted GNSS observations for the period of your survey. The Propeller Platform then uses that as the reference point.

This RINEX file must have an accurate location for the base in the header, as this is the location that the AeroPoints will be measured against. To properly process your data, Propeller needs RINEX version 2.11 with a minimum frequency of one observation every 10 seconds. It must cover the whole period of the drone survey and have no gaps longer than 10 minutes.

Commonly asked questions about Aeropoints and ground control

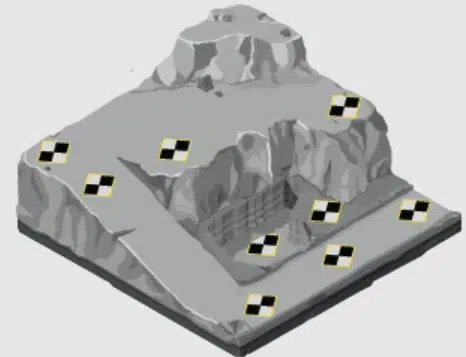

Should I place more AeroPoints in spots on my earthworks site where I need the most survey accuracy?

Basically, you need good AeroPoint coverage across your entire work site to ensure accurate survey results. Areas with poor coverage can negatively affect areas with good coverage, rendering the site model inaccurate.

Therefore placing AeroPoints on the highest and lowest points in the entire survey region, as well as at the edges is best practice for optimizing overall survey precision. Once you’ve completed this, if you have remaining AeroPoints, you can put them to good use by placing them in particular areas where you would like to obtain higher accuracy.

Notice in the image above that only nine of the AeroPoints are being used, and they don’t surround the entire site. None have been placed on the tallest point of the site and some are clustered together around important sections.

What is the best placement for AeroPoints?

What you need is an optimal geometry of AeroPoints across the entire surveyed area.

This is crucial, much more so than the number of AeroPoints in a particular geographic location. Placing points on the ground closer together in one spot doesn’t saturate their accuracy. When you perform a site survey; you cover your whole site, not only the “important” parts.

The goal is to create a shape bounding your entire site and place AeroPoints throughout the middle as evenly as possible, including placing them at the lowest and highest elevations. If you have a giant “air pocket” in the middle with no AeroPoints on it, “pinning down” the aerial photos to that survey area will be difficult.

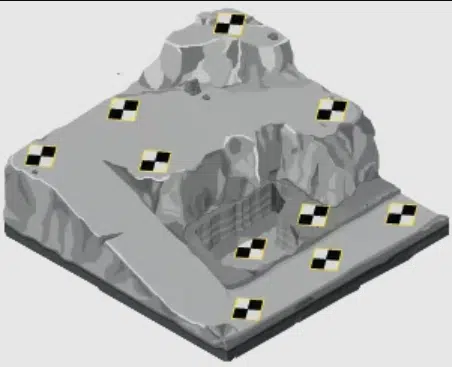

What is a good example of ground control point placement?

Here’s the same site again, but now with AeroPoints distributed with optimal geometry.

Notice that you can connect the dots and draw a shape around the whole site without taking your pencil off the paper—and the middle is covered. All ten AeroPoints are used in this example.

Naturally, you’ll need different configurations depending on the shape of your worksite.

When planning placement, remember the AeroPoints need to be set around the perimeter and throughout the middle. If not, your aerial data could be highly inaccurate or even unusable.

How do I fly my earthworks site with a drone using AeroPoints?

Drone flights using AeroPoints are flown like any other flight. The difference being that you’re now also capturing AeroPoints target data in your imagery that will later be used to increase the accuracy of your aerial map. Be sure your camera is focusing properly. If the AeroPoints are not in focus, the process will not result in high accuracy. Ensure you have good weather over the area you will be flying that day. High winds, low clouds, or precipitation can make flying and mapping difficult.

Once you complete your mission, you’ll be ready to process your aerial data. Next, we’ll explain photogrammetry and discuss two different processing methods and the pros and cons of each.

How to Process Drone and Ground Control Data After Surveying

Now that you’ve captured your aerial data with your drone and AeroPoints, what’s next? Using photogrammetry, you can process your data via RTK or PPK in order to get an accurate picture of your site.

For the non-surveyor, it may be hard to fully grasp what photogrammetry is, and it can be difficult to understand whether RTK or PPK is the ideal choice for automated job site data processing. Here, we’ll explain photogrammetry and take a high-level look at each earthworks data processing solution, discuss the pros and cons of each, and explain why most surveyors, and Propeller, prefer PPK.

What is Photogrammetry?

When it comes to getting your drone data in a fast and accurate manner, photogrammetry is an optimal choice for earthworks professionals, when compared to more traditional data capture methods.

During a pre-programmed flight path the drone will collect thousands of photographs of conditions on the ground. The science behind collecting the physical information of 2D photos captured by drones is referred to as Photogrammetry. Then by combining many overlapping images of the same features, photogrammetry software can be used to generate photorealistic 3D representations of topographical surfaces on your worksite. Photogrammetry processing software works by calculating the location for one feature, then the next, then the next, and so on until it covers your entire worksite. This happens millions of times to generate a point cloud, which is used to process the drone data.

How real-time kinematic (RTK) processing works

“RTK” stands for real-time kinematic. The term describes both onboard drone hardware and a data processing solution.

RTK is a differential GNSS (global navigation satellite system) technique used to capture survey-grade positional data. In essence, drones with onboard GNSS equipment communicate with satellites and a fixed base station to triangulate their location and correct their positional data in real time as they fly.

So, why does satellite data require correction? It might sound surprising, but satellite data is error-prone due to tropospheric delay (the signal path delay difference between the path through the atmosphere and the geometrical straight line path delay if no atmosphere was present) and other issues that arise when you’re communicating with objects orbiting thousands of miles above the earth.

To ensure the drone’s RTK receiver records accurate geocoordinates, another GNSS receiver (also called a “base” or “base station”) is placed on solid ground. It sits—without moving—on a point with known coordinates. An active base station on the ground sends raw GPS data to the drone and the drone’s onboard GPS unit then combines that info with its own observations to accurately determine its position relative to the base. Incorporating the base station boosts the accuracy of RTK from about 1 meter to a centimeter-level range.

However, in an RTK workflow, the level of accuracy depends on an uninterrupted connection between the base station and the drone—a connection that can be broken fairly easily. Signal loss can occur for several reasons: patchy or unreliable signal, flying behind obstructions like trees or buildings, or antenna orientation during a turn. When that happens, the drone data is unreliable until the drone regains its connection with the base.

RTK Pros:

- Drone data capture is complete immediately after flight

- Real-time, accurate drone positional data

RTK Cons:

- Requires stable connection between base station and drone

- Short-term loss of connection means significant loss of data

How post-processing kinematic (PPK) works

PPK is a data processing workflow. Unlike RTK, it’s not hardware, but PPK workflows do use RTK drone technology.

PPK stands for post-processing kinematic. Propeller’s PPK workflow uses RTK drone hardware to collect accurate positional data during a survey flight. But as the name implies, the actual processing of that data occurs after the flight is complete, not in real time.

In a PPK workflow, the drone still attaches geo coordinates to each image, based on an onboard RTK GNSS unit. And a base unit or base station still records positional information, triangulating the drone’s position in space. Here’s is the difference between RTK and PPK:

The two sets of GPS data (one from the base, one from the drone) are matched using timestamps on the photos. The more accurate positional data from the base then corrects the drone data to produce a dataset that also achieves centimeter-level accuracy.

With PPK, the base station and the drone do not need to maintain constant contact during flight, because all the data is recorded and reconciled after the flight. This becomes very valuable when surveying sites with an unreliable signal or larger sites. In most cases, if you’re using a PPK-enabled drone, usually only one AeroPoint is necessary to serve as your base station/GCP!

PPK Pros:

- No need to maintain connection between the RTK base station and the drone during flight

- Much simpler setup than RTK, and fewer points of failure

PPK Cons:

- Data is processed after the flight. With processing time brief delay between flight and data output

- Some systems require RTK to enable terrain following functionality

Why Drone Surveyors prefer PPK

PPK is actually more reliable than RTK, with the same level of accuracy because you can correct any errors after the fact, once those gaps are known. Because a constant connection between the base and drone is not required with PPK, you don’t have to worry about reduced accuracy if a signal is interrupted. PPK allows you to fly longer distances with technology that’s easier to use.

And with Propeller, the “post-processing” is handled by our team, so there’s nothing for you to manage. It’s often as simple as placing a ground control point, like Propeller’s AeroPoints, flying your drone for as few as 10 minutes, and connecting to WiFi after the flight. We handle the rest. Propeller’s PPK workflow makes drone surveying faster, easier, and more reliable.

How are earthworks companies using AeroPoints for ground control to achieve survey-grade accuracy?

Here are just a few ways that earthworks industries are using the accurate site data they get from drone surveying and employing smart ground control with AeroPoints.

- Aggregates/Quarries: Conduct high-frequency drone surveys of the jobsite to capture changes on the quarry floor as they occur

- Civil Construction: Capture pre-bid topographic surveys faster and more cost effectively and track how much earth you’ve moved between surveys and measure stockpile volumes

- Mining: Accurately measure pit angles, calculate blast volumes, and manage material movement

- Landfills/Waste Management: Perform quick, accurate calculations of compaction densities and remaining airspace

In the case studies below, you can learn about some of the advantages Propeller customers are getting by using AeroPoints to enhance their drone surveying.

A simple process to accurate data that can lead to more business

Keith Taylor, the survey manager at D.H. Griffin Infrastructure, explains how simple it is to set up his site for surveying from distributing his AeroPoints through launching his drone and uploading the data for processing. Read the full case study.

“It’s very simple using AeroPoints with Propeller’s PPK,” says Keith. “The way the whole workflow is set up…I’m confident in the accuracy of the data I’m getting.” – Keith Taylor

Keith also shared how having more accurate data from drone surveying and using AeroPoints as smart ground control has given D.H. Griffin a competitive advantage for their business.

“We had a project where there was a discrepancy between what our drone was seeing in the existing topo versus what was in the survey that was done for the design. We were able to use that information to negotiate additional work.”

Capturing accurate data is simple and a great timesaver

Salsbury Engineering is a grading and earthworks contractor based in Southern California that specializes in complex industrial projects involving more difficult grading and excavation schemes, such as airports, hospitals, and powerplants. Vice President Jon Gauthier explained how using AeroPoints allows them to fly shorter missions, which is a big timesaver for their project teams. Read the full case study.

“We use AeroPoints, which allow for shorter drone flight times and more robust positioning data for our surveys. After flying a mission, we simply upload the survey data to the Propeller Platform and obtain accurate site models along with easy-to-use reports, which frees up valuable time for our project teams.” – Jon Gauthier

Keeping workers safe on a busy job site

Using AeroPoints can also help enhance worker safety. For example, walking around an active landfill site to survey manually can be dangerous. Sheckler Excavating builds landfills and their most recent cell maintained three different dump sites their trucks traveled between, ranging from 20 feet from the cell to a half mile. Read the full case study.

“With our drone, I can stand just outside our office trailer onsite, set up AeroPoints and fly over the landfill cell. Nothing is at risk and nobody’s moving around trying to avoid trucks and excavators.” — Nicole Sheckler.

Obtaining accurate data, fast with AeroPoints and Propeller

Mehmert Tiling uses AeroPoints and Propeller for topography mapping, ground control, and quantifying their stockpiles. Read the full case study.

“We definitely value the ability to do surveys with Propeller, and have been pleased with the accuracy. We’ve compared the data we get from Propeller with rover surveys, and it comes out spot on, in about an eighth of the time. We also use AeroPoints for ground control…the PPK workflow and AeroPoints have been a great tandem.” – Brent Mehmert

As you can see by these case studies, earthworks businesses continue to adopt drone surveying programs to map and measure their worksites and use smart ground like AeroPoints to obtain fast, accurate data about how their projects are progressing.

When you always have the current status of a site at the ready, you can also proactively identify (and eliminate) errors and risks.