Hensel Phelps Is Using Propeller to Track Earthwork, Share Data on Hawaii State Hospital Build

Headquartered in Colorado, Hensel Phelps is a nationwide construction and contracting company. They serve every corner of the US, including Hawaii. And it’s in Honolulu that they’ve been hired to build the Hawaii State Hospital.

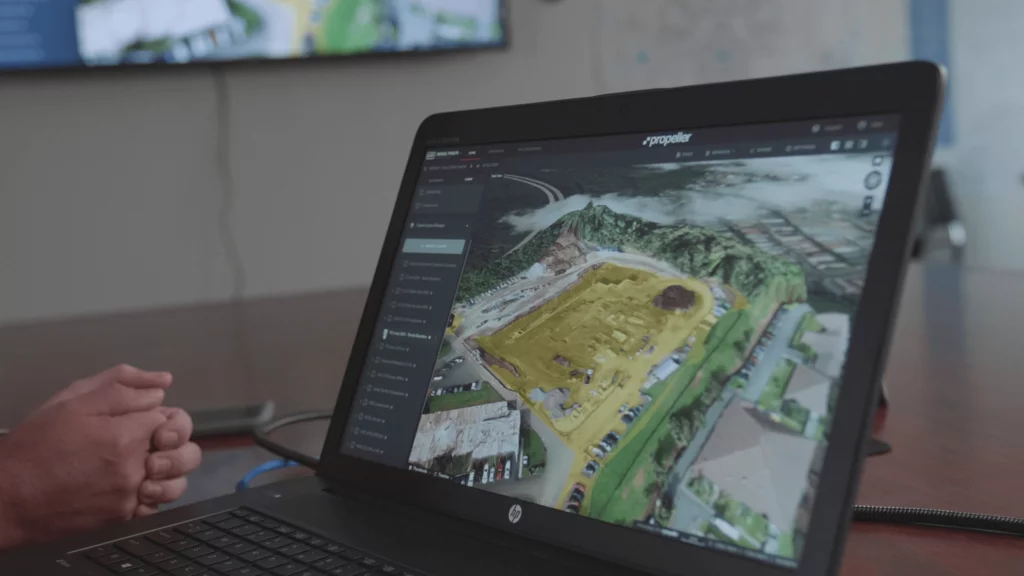

To track, map, and measure this jobsite, Hensel Phelps is using drone surveying and Propeller’s 3D site surveys.

Self-performing earthwork for the first time made the test case for Propeller

Building Hawaii State Hospital was the first time Hensel Phelps did not contract out the earthwork phase of their operations. “We decided to use this job as a pilot example,” said Area Superintendent Andrew Low. “Some of our guys in the estimating department wanted to really track production and quantities and [costs].”

Around this time, Hensel Phelps started looking into different software, one of which was Propeller.

“Some of our project superintendents were against it, they had some tricks up their sleeves, some experience they could track this information on their own,” noted Low. “Then some of the younger staff, who had very little experience tracking the operations of earthworks—we were all for it.”

Hensel Phelps can now hire their own operators instead of outsourcing earthwork

Before using Propeller, “we’d usually hire a subcontractor [and] use their expertise to help us plan our work: how we’re going to excavate, how we’re going to grade, how we’re going to backfill,” said Low. “With the help of Propeller, we can hire our own operators and we can go out there and plan our work using this software.”

When it comes to planning and tracking their work, Propeller let’s them track their progress and productivity much closer to real-time. For this project, Hensel Phelps is surveying their site by drone every two to three days.

Flying their jobsite at that frequency means “we’re able to see production. We’re able to make reports based on what had actually happened each day,” said Field Engineer Erik Johnson of using up-to-date data to make decisions. “We’re able to compare how much fill we have remaining on the project and stockpile quantities we’re able to utilize.”

Beyond earthwork, Propeller helps with innovation and safety

As a company, Hensel Phelps is always looking for the next best thing to improve how they work and build, known as the Hensel Phelps Way. It’s an idea that applies to all their work, but when it comes to safety, it’s an even bigger priority.

“For safety, especially, we use [Propeller] for orientation, trenching, excavations, and things like that,” said Safety Engineer Tyler Stumph. “It helps a lot with making it easier for me, for our staff, but also for making it safer for the guys out on the field.”

Propeller is used both in the field and office

It’s hard to overstate the value of up-to-date 3D site surveys for an ongoing build. From the real-world visuals to the recordkeeping, Hensel Phelps uses Propeller in the field and in the office.

Here are three examples of how they’re using it today on the Hawaii State Hospital:

1. Site planning and logistics

One of the most obvious uses of 3D site maps and drone imagery is planning. “We really encourage all of our field staff and office staff to utilize [Propeller] to plan our work,” explained Low. “We’re looking at quantities, we’re using the drone pictures [. . .] to do our site logistics plans.”

Beyond that, they also use Propeller to inform other stakeholders and subcontractors about site conditions or potential issues “We’re using it to help in our sub coordination meetings to show where underground utilities might conflict with an excavation we have out there,” added Low.

2. Sharing up-to-date information with team members

Propeller has also allowed the project team to better share information between one another.

“You can relay real-time project information or data to them, as far as production, quantities, budget—really a lot of things,” said Johnson. “They’re able to share that in a more refined manner than rough quantities on paper. It’s really easy to visualize the site. You can show them a lot more information.”

3. Better balancing the jobsite with cut/fill maps

But beyond visualization of current conditions and future designs, in-platform tools assist teams in the field, too.

“You put in these civil elevations and [Propeller] will tell us, you’ve got more dirt to add over here, more cut to add over here,” said Low. Propeller can calculate the cut/fill numbers in a snap and display them over a map of the terrain. “We’re not hauling off extra dirt, we’re keeping and maintaining the most accurate amount of dirt that we need.”

With Propeller, Hensel Phelps improves jobsite efficiency

“If we didn’t have Propeller, there’d be a lot more people on our projects, that’s for sure. It’d take a lot more people to get done what we can get done with fewer right now,” said Lead VDC Engineer Mark Blacklin.

This is true on many levels of the job. It takes fewer people to collect site data, and less time to do it, with drone surveying. But also, Hensel Phelps uses Propeller to outsource its data processing, so they don’t have to expend the time of in-house personnel.

“With Propeller, we can capture [a] dataset, hand it off, and 12 hours later, we get a dataset back,” explained Blacklin. “That’s remarkable.”

Data processing, 3D visuals, easy sharing, and accurate data—all of which Hensel Phelps needs for an efficient worksite today. Propeller makes it possible. “It’s the latest technology, it’s easy to use, and it gives us accurate information,” said Low.