Family-Owned Business With Large Footprint Sees 10X ROI from Drone Program

Meet Rory Hall, operations manager and Propeller champion at Grade Tech

Grade Tech Services is a family-owned company dedicated to providing grading and excavating services exclusively to power generation companies across the US. They’re headquartered in Midvale, Utah, but their footprint stretches far beyond state lines, servicing projects in Washington, Oregon, California, and most of the western United States.

They’re committed to expanding their reach, claiming to be able to be anywhere in the U.S. in just 24 hours to begin operations. One project at a time, they’re building America’s power infrastructure.

Like most small business owners, Rory Hall wears anywhere from three to five different hats in a single workday. While on paper, Rory is Grade Tech’s operations manager, once he starts describing his daily responsibilities, it becomes obvious he’s also an unofficial surveyor, tech champion, estimator, pilot—the list goes on.

When Rory comes to work, his primary focus is doing whatever he needs to do to keep his crews moving. When asked what a typical day looks like, Rory’s answer was simple: there isn’t one.

To free up time in his day, Rory has always turned to new technology that helps his team operate more independently and efficiently. Right now, they’re relying on over ten different software systems to keep all their high-profile projects on time and on budget.

Although Grade Tech doesn’t shy away from digitization, they’re only interested in making safe investments where they’ve clearly outlined the need, impact, and ROI before getting their feet wet. They’ve been using GPS since the early days, but didn’t get into machine control until it became economical. It’s a healthy skepticism that keeps them on the leading edge, rather than the bleeding edge, of new tools.

Naturally, Rory’s openness to technology led him to explore drones on the worksite.

He describes his early drone days as discouraging and difficult. Between the ground reference points, trying to establish new workflows for existing projects, and all the initial buy-in, drones seemed like more trouble than they were worth—at least until he found Propeller through the Komatsu Smart Construction Initiative.

How Grade Tech uses drone data to scale their business

Today, they’re flying every new project they’re bidding on and every active project at least once a week. So, what changed?

This is what’s changed: They’ve realized that drones are just the beginning of a much greater workflow that’s now saving Rory 10-20 hours a week, and Grade Tech, tens of thousands of dollars a year.

Here’s how they’re using drone data to scale their business:

→ They’re flying two drones with Propeller’s PPK workflow

Grade Tech flies their drone pilot down to each of their sites to capture the current state, and not just on active sites—they’re flying every site they bid on. This helps them build a complete visual record of what happens throughout the project lifecycle. It’s become an insurance policy that they can use to immediately resolve any conflicts or miscommunication.

They’re flying with Propeller PPK, a comprehensive and integrated drone surveying workflow that combines DJI’s Phantom 4 RTK drone, “smart” ground control, and 24-hour data processing.

Before, ground control was a major hang-up for Grade Tech. Now, they’re using AeroPoints to achieve 1/10ft accuracy without the hassle.

Looking ahead, Rory says his ultimate goal is to put a drone in every one of his foremens’ hands so that they can fly their jobs once or twice a week, and upload the data themselves.

→ They’ve traded in guesswork for verifiable progress reports

Ground-level progress photos of what’s happening on site and manual calculations only work for so long, especially when you’re trying to scale your business. At least, this was the case for Grade Tech.

Before they started using drone data to measure progress, most of their timelines were the product of guesswork—visually approximating where they were at and tracking truckloads to estimate earthwork status.

Now, they’ve traded all those rough estimates for verifiable quantities. Once they upload a drone flight to the Propeller Platform, they’re able to measure stockpiles and cut/fill in just a few clicks, with greater accuracy than ever before.

With quick access to project data, Grade Tech’s been able to….

And the benefits don’t stop there. Now, anytime there’s any kind of finger-pointing, Rory pulls up an interactive, 3D map from their most recent flight. From there, he’s able to squash any conflict with documentation of exactly who’s accomplished what and where.

Once word got out that Grade Tech had this secret weapon, the finger-pointing came to an end, and customers started reaching out to them for a whole new reason—they want access to Grade Tech’s data for their own verification and reference purposes.

→ They’re saving $3,500 a day using up-to-date orthos

Since Grade Tech has a fairly small team, they have to be strategic about where they’re sending both their people and their equipment.

Propeller gives Grade Tech the bird’s eye view they need to manage their projects more efficiently. In the past, their field-based teams have over- or under-estimated the amount of time they need to complete a job out of fear of being wrong.

Other times, it’s other contractors who create scheduling inefficiencies. Most superintendents want their subcontractor to arrive sooner than they’re required. And when you have a small team, downtime comes at a high cost—approximately $3,500 a day, according to Grade Tech.

Now, Rory’s surveying each site to capture initial state, prior to sending his whole crew down. And on top of that, he’s pulling up a 3D map of each active job in the Propeller Platform to measure what’s left to do and communicating that to his foremen.

This way, he’s tightening up scheduling on both ends:

- Avoiding downtime by only sending his crew out when the ortho indicates that the project’s ready for them

- And keeping his team motivated with up-to-date data on what’s left to do.

The ROI Breakdown

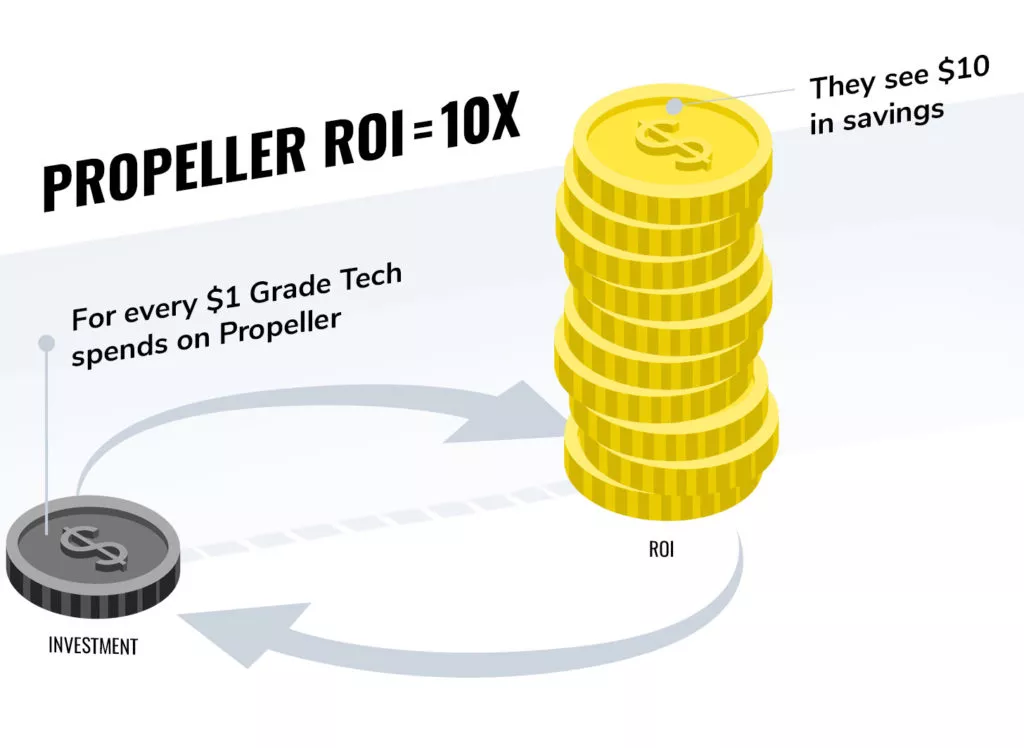

Between reducing downtime and being more precise with their earthwork, Grade Tech quickly made money back on their investment—tenfold their original Propeller buy-in.

Operations Manager, Rory Hall, approaches the upfront costs with a refreshingly objective perspective. He says, for Grade Tech, Propeller is “too expensive not to own.”

Too often, people are fixated on the upfront costs, but Rory views this is a case of “not seeing the forest for the trees.”

It’s not about weighing the cost of each survey against the immediate return; it’s about avoiding four or five days of rework on a job where the foundation’s being laid incorrectly, or calculating cut and fill to avoid exporting material offsite, saving 10-20k from just one calculation.

During our conversation with Grade Tech, Rory said he was saving so much money that he could buy a new drone every week. Though that probably doesn’t make sense to do—what he meant was that Propeller is a low-risk, high-reward purchase that opens the door to profitability in areas of your operation that you haven’t yet realized are costing you.

“From my standpoint, with what we do, ” says Rory, “every dollar is 10 to 1.”