End-of-Month Reconciliation on Your Quarry with Drone Technology

Originally published by the International Cement Review.

In the last few years, commercial drones have become more and more common on quarries all over the world. But how do common aggregates workflows change when using drone technology?

Drones improve data-capture speed and are much more user-friendly than traditional equipment. For specific tasks, however, drone technology can totally overhaul traditional methods. Let’s look at how drones improve the end-of-month reconciliation process for a quarry.

All quarries need accurate information on stockyard tonnage to fulfill work orders and be financially solvent. But too often big write-offs have been par for the course. Even when outrageously high, they’re an accepted status quo.

With traditional reconciliation methods, a quarry is surveyed via plane in an aerial flyover every six months. Write-offs also happen on that biannual schedule.

But you can be out by a lot of stock in half a year, and those aerial flyovers are very costly on their own Essentially, you’re paying lots of money to know that you have to write off lots of money.

Drones allow you to survey your own stocks and therefore make slight adjustments each month to mitigate the mandated six-month check.

Time and budgetary constraints of the traditional method

Conventional reconciliation takes days of work. Typically, a quarry manager will be taking a best guess on stockpile volumes, using the numbers from the last aerial flyover and from contractors who are moving material around. Or they might use a trundle wheel to measure the base of a pile and estimate the height—and do that again and again and again. Then with some simple math, they get a very rough estimate of total volume.

With so much speculation and out-of-date information, it’s no surprise why the numbers are so far off every six months. These old tactics have never been enough to get you the answers you actually needed about your quarry as often as you need them. In many cases, you’re set up to lose.

Reduce costly write-offs with easy, accurate drone surveying

Drones are no longer novelty gifts. They are worksite tools and profit generators. Across the board, they lower costs and the time it takes to survey without sacrificing accuracy.

Each craft is thousands of dollars less than a base station and rover. If you’re using a mass-produced UAV like DJI’s Phantom 4 Pro, you pay a couple thousand dollars for an extremely valuable tool.

Special training is not needed to capture your quarry’s data, so you or existing personnel can do it.

You can fly a site in a few hours instead of days. The hardware setup time is minimal. The drone is simple to operate. The flight is automated.

It’s most efficient to plan the flight and ground control back in the office. This streamlines placing ground control points on the quarry and allows you to notify those on site of your movements. Flight-planning apps like Ground Station Pro allow you to preprogram a flight path.

Once you’ve set up the drone outside, just press Go. The drone flies along its route taking pictures with proper overlap and returns home when it’s done. You just keep it within line of sight throughout the flight and avoid sending people to walk over dangerous piles or through high-traffic zones on site.

(Depending on where your quarry is located, you might not need any formal licensing—as with Australia, where flying small drones at low altitudes is okay for anyone as long as you’re registered with the Civil Aviation Authority. In the US, you need a Part 107 license from the FAA, which only takes a simple test to obtain.)

Leave the difficult data processing to the software

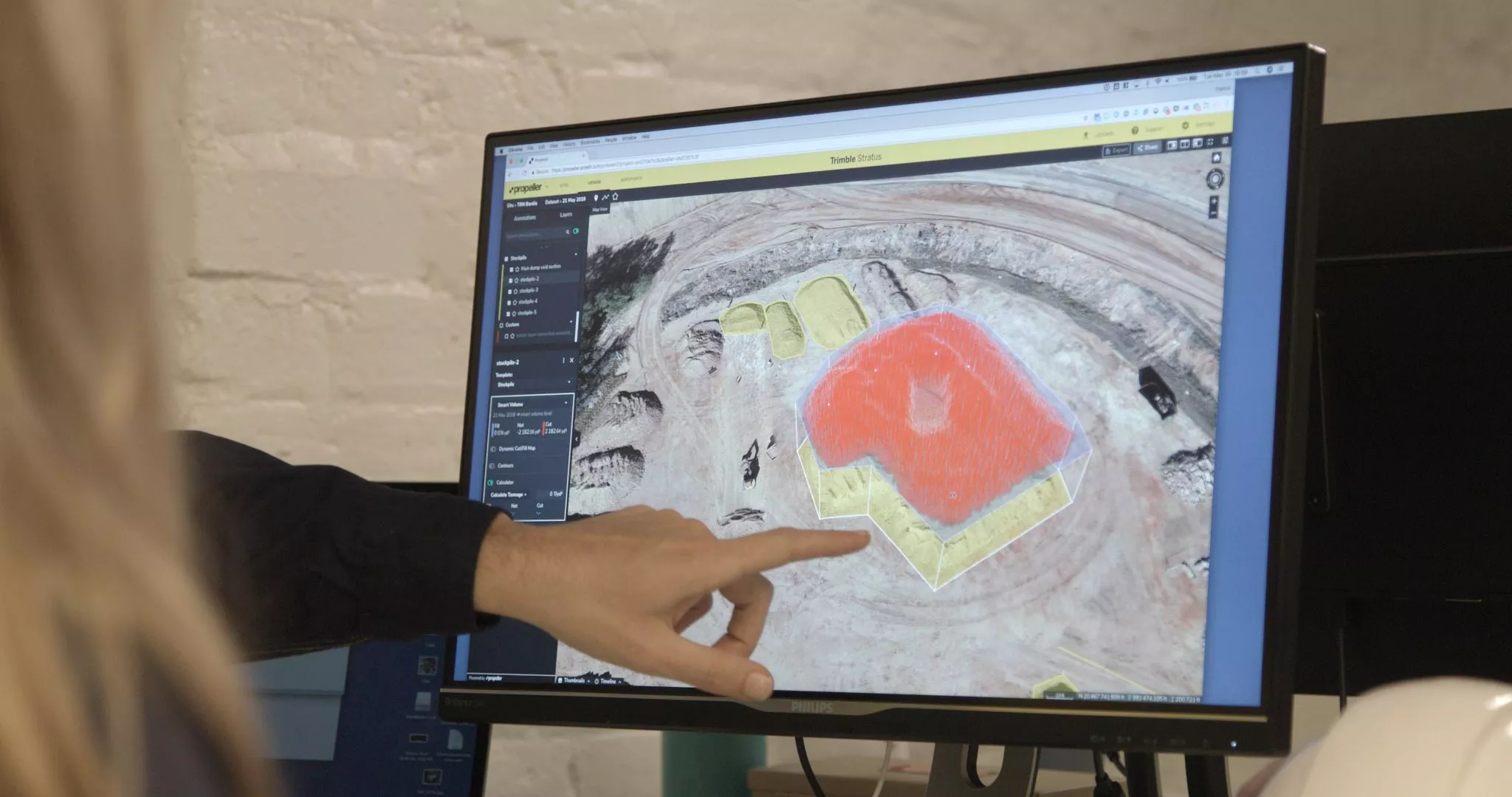

Those few hours are all the time you need to expend to get the data you need for accurate reconciliation. Processing software like the Propeller Platform does all the heavy lifting and frees up your time for site analysis.

The software takes in all your drone imagery, ground control data, local site calibration, etc., and processes it for you. Using photogrammetry methods, it’s able to render an accurate, visual 3D survey of your quarry. It’s light-years beyond spreadsheets and columns of abstract data.

With traditional survey methods, processing data was just as difficult as capturing it—maybe more so. Not everyone on your quarry is an expert in the complex science of photogrammetry, let alone trained to use the complicated desktop software programs needed to crunch the numbers.

Propeller serves as that expert and returns more detailed site data in less time. About 24 hours after uploading, you get a email saying your survey is ready. Since the survey is browser-based, you can access everything from your device, wherever you are.

And because these surveys are visual and 3D, you’re seeing a representation as close to the real world as possible. It’s immersive and takes abstraction out of the picture, letting you have a visual conversation with your team or your boss.

Quickly get stockyard tonnage numbers you can rely on

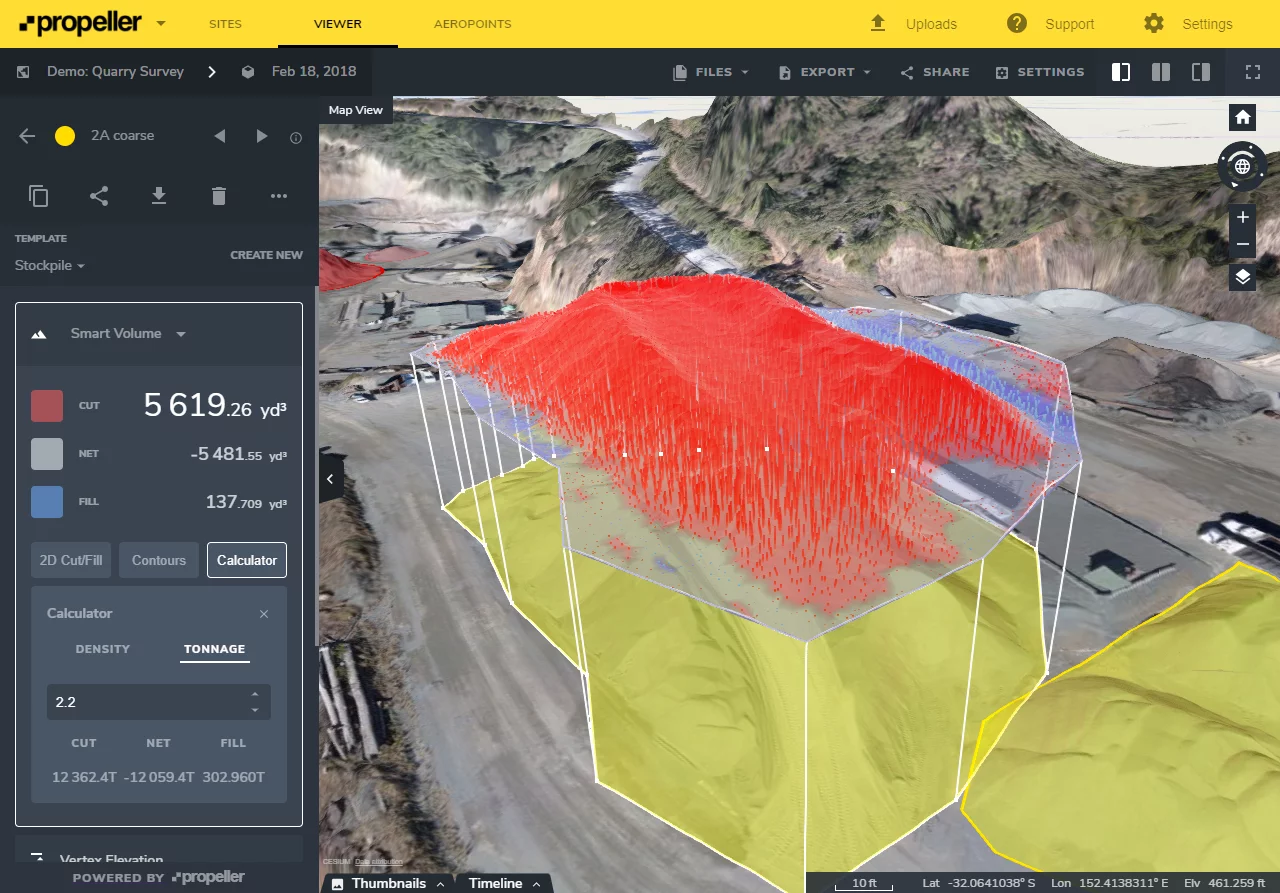

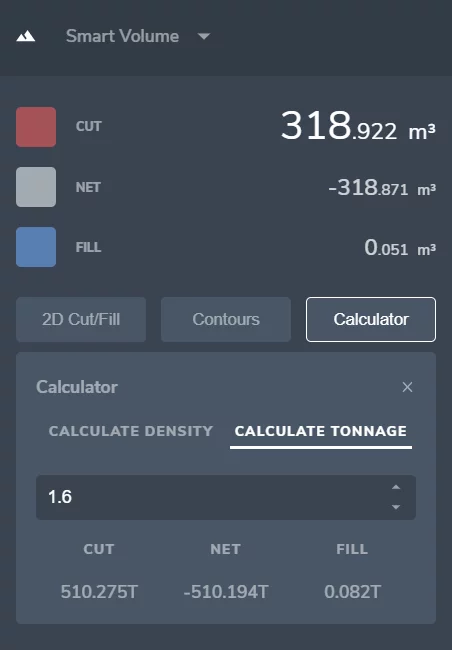

Propeller was built for regular people, not scientists. Its intuitive design takes minutes to master. With its sophisticated calculators, you can quickly find tonnage values for your stockyard and make sure everything lines up with the amounts given by subcontractors.

Not only do you see your site in 3D, but you also measure in 3D. That simple one-to-one correlation between the measurements and what you’re measuring enables easier understanding and higher confidence in your results.

For example, say you want to get the tonnage of a particular stockpile. Just click around the base with your mouse. The computer figures out where the toe of that pile is, then calculates the volume. If you know the density of that material, you can enter it in the calculator and get your tonnage in seconds.

This applies to your entire sales yard. With accurate tonnages on all your material, calculating the monetary value of your current stock—or an individual pile—takes seconds.

Since drone surveying is significantly faster and easier to do, you can get updated information on your stockyard as often as you want to fly. Multiple 3D site surveys over time provide a visual timeline of changes on your quarry. With it, you can see progress and productivity at a glance.

Collaborate and report using a single source of truth

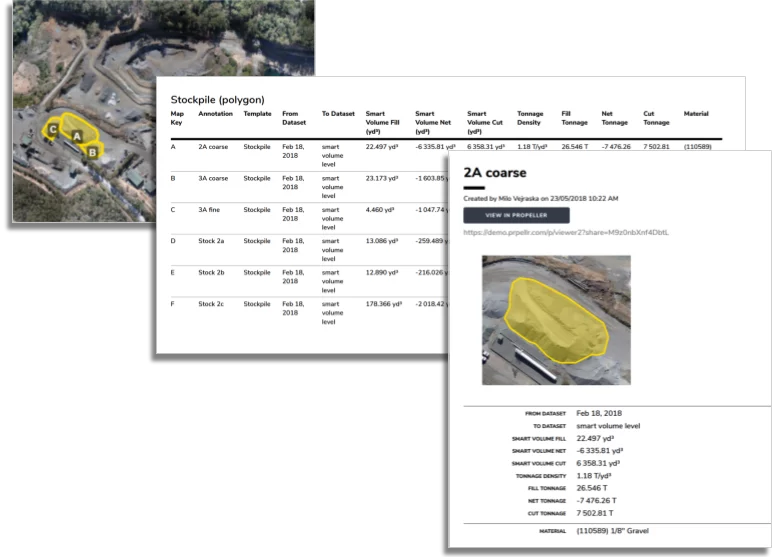

When you’re ready to report out your end-of-month numbers or do a biannual reconciliation, sending detailed accounts to the higher-ups is made easier with turnkey reports, available in PDF and CSV.

You can also grant your boss or a team member access to site data in the platform. Distinct permissions levels let you throttle how much any one individual sees of your quarry’s data, so you can ensure everyone is on the same page and can see the data and measurements visually.

End of month reconciliations are faster, easier, and more accurate with Propeller

Visualization software and drone-captured data goes beyond better numbers. It’s raising the bar on workflows like end-of-month reconciliations by allowing you to measure and manage your site yourself.

Additionally, having drone imagery coupled with good ground control and a processing platform like Propeller, democratizes site data. The 3D nature of the survey and its intuitive tools makes understanding quarry data accessible for everyone.

Drones are less costly and easier to use than traditional surveying equipment—and more accurate than eyeballing stockpile volumes. They put the power of frequent surveying in your hands. And having accurate stockyard numbers every month means drastically reducing future write-offs, saving everyone on site money and boosting quarry efficiency.