How to Collaborate Better Using Drone Data and the Propeller Platform

Keeping everyone on your worksites up to date with the best and most recent information possible is critical for ensuring optimal productivity. Collaboration challenges span the entire life of any project, like liaising with consultants, mobilizing contractors, monitoring progress and production, QA, and closeout. At each stage, ensuring the right parties have the information to understand a project’s needs and complete their work on time, on budget, and to specification is critical to good decision making and success.

The Propeller Platform makes it easy with intuitive tools and a 3D interface.

The traditional approach

Collaboration on worksites has traditionally centered on two methods: drawings and physical inspections. While both methods are “tried and true,” the obvious pitfalls are almost as old as the methods themselves.

Drawings

One of the major problems with collaborating using drawing is the difficulty of communicating the context between your actual site and a set of drawings. As one of Propeller’s customers recently put it,

“Most people on site don’t understand drawings. . . . Using Propeller I can show new contractors around key areas of [the] site.”

—Robert Usher, Project Manager, Boral (Quarries, global)

Management and version control usually lies with a small design or engineering team. The majority of site-based workforces don’t have access to the expensive software required to stay abreast of design.

Inspections

For most people in the field, the default way of communicating tends to be visually inspecting work. Whether it’s a during mobilization, daily briefings, or as part of QA checks, having people observe work, or areas marked for future work, is the foundation of site-based communication for most. The reason is simple—it works. Nothing beats the directness of seeing the work insitu.

However, this method is expensive. Having personnel on site to inspect before, during, and after works requires resources to be allocated. For example, in deep excavations around blasting or when working with hazardous materials, physical inspections also bear an unacceptable safety risk. For your nonsite-based workforce, including outside stakeholders, getting to site is often not possible. Photos and drawings are a poor substitute for in-person visits and loses a lot of context.

Drone data analytics in 3D

When it comes to getting an up-to-date picture of your worksite, a 3D model provides the most referenceable and scalable solution. Using 3D data captured by drone, anyone can produce a model that’s visually recognizable and can therefore be used for easy communication by anyone on- or off-site.

In the Propeller Platform, adding designs—whether as linework or design surfaces—also makes it possible to visually monitor and track progress towards a design. Because the model is 3D and uses up-to-date photographs, it’s easy to recognize how the design relates to the current state of the site.

In hazardous work areas, drone data is often the best and only way to completely eliminate unacceptable safety hazards, while also getting survey-grade measurements of high-risk areas.

For off-site users, like tendering contractors, designers, or head office-based personnel, using a 3D site model provides a realistic alternative to costly in-person visits. An accurate and up-to-date model, rich with context provided by notes and shared files, allows off-site users to move around freely, getting a whole-of-site perspective of how things work.

Benefits of collaborating in 3D

As we have seen, worksites are a 3D environment conventionally managed using 2D tools. Using a 3D model improves communication by giving everyone a tool they can understand.

On sites with multiple contractors working simultaneously, interface management is a core collaboration challenge. The easiest way to manage the issues associated with multiple sets of design drawings; different, often overlapping areas of work; and competing priorities is to equip everyone with an accurate, understandable picture of the site’s status and progress, as well as where it’s headed.

As one US civil contractor puts it,

“Propeller gives us the ability to compare [. . .] fieldwork to construction models quickly and accurately, this enables us to have more efficient and effective coordination meetings.”

—Hamzah Shanbari, Virtual Construction Manager, Haskell (USA)

Coordinating in 3D allows important conversations to happen in context. You can be speaking from an office but be looking directly at a work area, removing guesswork.

The essentials of an effective 3D collaboration solution

Easy to produce, accurate, and up-to-date 3D data

For your 3D collaboration solution to be effective it needs to be a model that is accurate, easy to navigate, and easy to produce. Propeller includes a simple workflow that works with any drone. Data is processed by experts in under 24 hours and is accessed through an intuitive 3D interface that can be easily navigated by most users within minutes, with zero training.

Accessibility

Effective collaboration requires that everyone can use the necessary tools to be part of the conversation. But the per-install cost of most traditional software, along with ongoing maintenance, makes it cost prohibitive for most organizations to provide every individual with access.

Using a browser-based tool, like the Propeller Platform, instead of traditional desktop software means that anyone with an internet browser can use the tool without installing any software. Additionally, Propeller’s site licenses have no limits on the number of users you can share your site with, making it simple and cost effective to give everyone the best collaboration solution available.

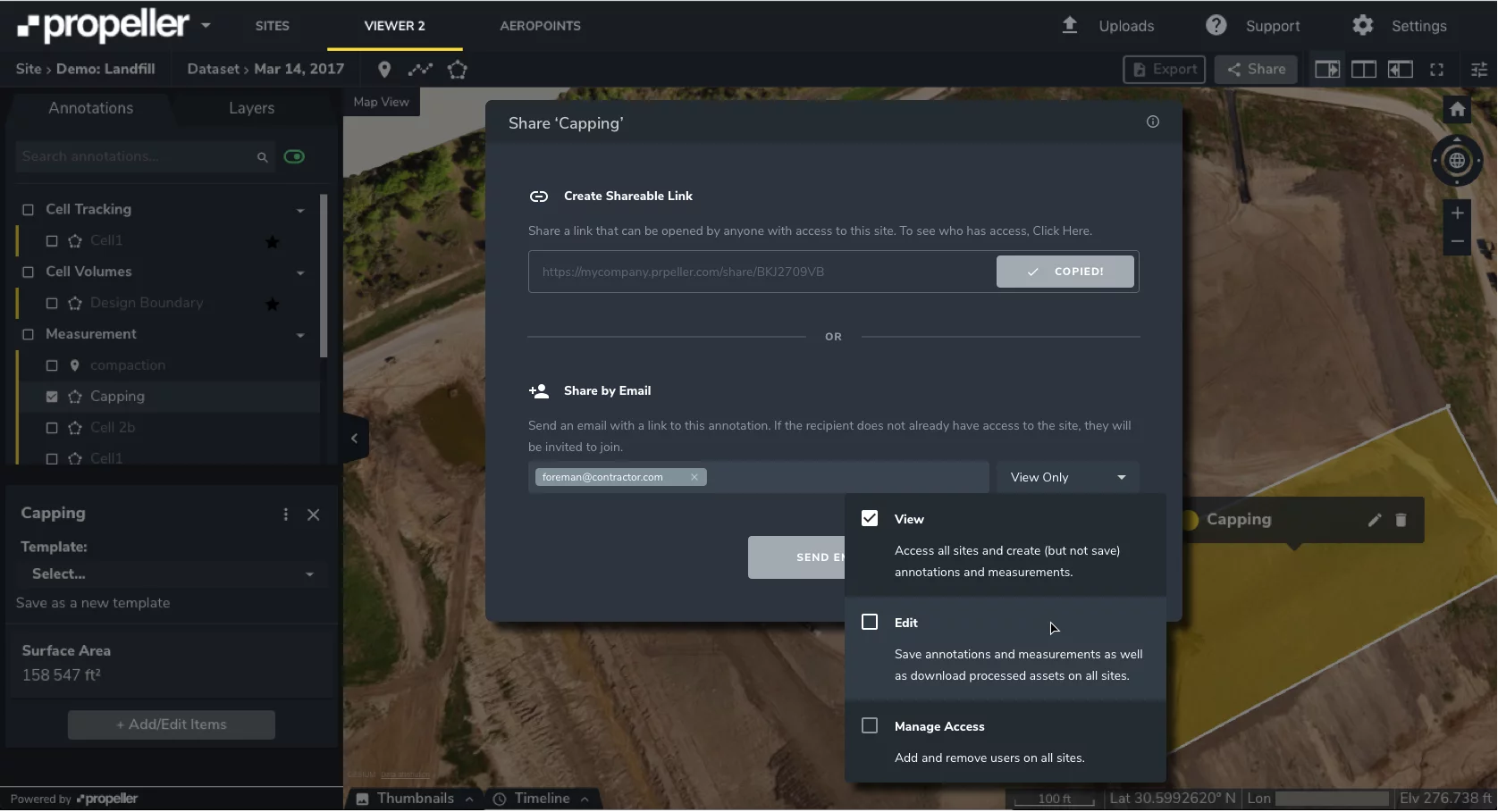

Easy and secure sharing

Availability is important, but so is ensuring data about your site is only being shared with the right people at the right time. With the Propeller Platform, whether you’re sharing with your site team, head office, or contractors and consultants, you can ensure the right people have access to the correct information about your site at all times.

The Propeller Platform makes it easy to share your site using flexible, clear options, like adding teammates and generating snapshot reports (PDF or CSV) for one-off and external sharing.

Once your team has access, they can collaborate and share individual measurements or features. They can also upload additional data to surveys, closing the loop between a site-level overview and specific documentation related to work completion. Linking flight documentation, inspection reports, or hazard analysis back to a relatable 3D model allows anyone to understand exactly which part of the site a document relates to.

With simple 3D tools, which allow your people to accurately communicate from wherever they are, it’s possible to unlock cost savings and productivity benefits that come from better collaboration and a site where everyone can see and understand what they’re doing.