Queensland-based Cheshire Contractors Uses Propeller for Insurance Claims, Faster Surveying

Back in August 2018, we spoke to some new users of Propeller about how 3D surveys helped scale their business. Now, Cheshire Contractors, a mid-sized construction company based in Queensland, Cape York Peninsula, and the Torres Strait Islands of Australia, have been Propeller customers for the better part of a year.

Today, we check back in with them to see how their workflows have changed since using Propeller and drone surveying in their business.

We spoke to Shannon Cheshire, a contracts administrator and foreman at the company, about using Propeller to address fallout from a huge flood on one of Cheshire’s projects and other issues.

After site flooding, Cheshire uses Propeller for insurance claims

Cheshire Contractors was hired to build a massive man-made recreational lake. The site, located Hughenden, Queensland, is roughly 25 hectares (61 acres) in total and stores 715 megaliters of water (189 million gallons). That’s more than 286 Olympic-size swimming pools.

When completed, the recreational area will have beaches, BBQ areas, and playgrounds. “It will be an oasis in the outback when it’s finished,” said Shannon.

This area of Queensland had been in drought for the last seven years. When the project was about four weeks from completion, it suffered major flooding. It was reported that some of the surrounding areas recorded a one-in-two-thousand-year flood event.

“With all the rain, the lake filled up and then overflowed,” noted Shannon. “We’ve drained all that and now are trying to dry it all out and tidy up the site.” When the lake is completed the locals will have to wait for more rain to fill it up.

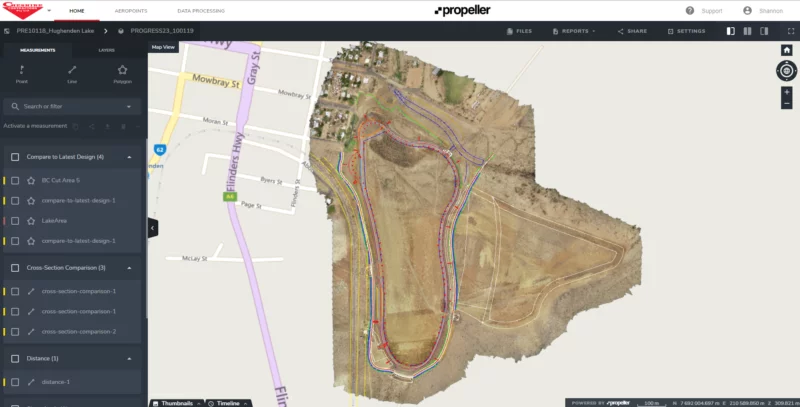

As extreme as the flood may sound, it could have been worse. “We’ve been able to use Propeller for our insurance claim, because it keeps a record of where we were at on the job,” said Shannon. “For all our progress claims, we’ve provided access to the client and the consultant via a visitors’ site, so they can jump on and check what they need to verify claims and quantities.”

Despite disrupting work, the flood did improve one aspect of the area. “It’s unbelievable here actually,” Shannon noted. “Before it was like the typical Australian outback, mostly red dirt and a few small bushes and trees. No greenery. Since that rain came through, within ten days, it’s all bright, lush green. The difference of the landscape is unbelievable.” (Before and after pictured below.)

Propeller facilitates easier client communication

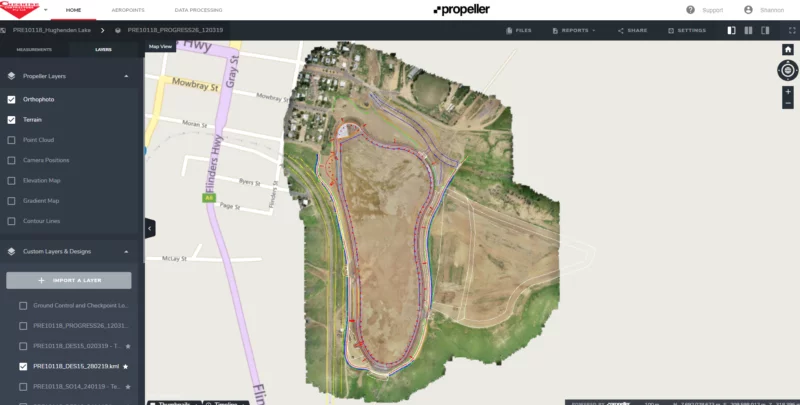

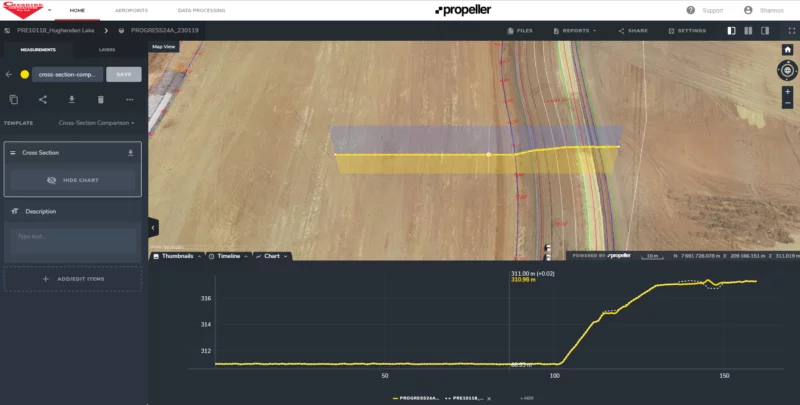

Cheshire also uses the Propeller Platform to visualize and analyze their drone survey data. With the big-volume jobs they do, quantities are what they deal with most. “Basically, measuring how much dirt we’re moving and compare to our production schedules,” said Shannon. But they use Propeller as a bridge with clients, too.

“We’re using it with current clients. With new ones, we’re trying to show them what we’re capable of with the new technology,” said Shannon.

At this stage, they’re working on getting Propeller to be part of their standard operating procedure. “When we supply the client with anything to do with survey, we give them a report from Propeller and it shows the site and quantities and whatever else. I think it encourages them to use us more.”

Presently, they might price two dozen jobs per year, but only use Propeller in three for various reasons. “But when we get that opportunity, we take it and use it to our advantage. Potential clients see [Propeller] and go ‘wow, that’s amazing.’”

For the jobs on which they use Propeller, “we create a special [portal] for the client to verify that the quantities in our claims are correct. It saves any arguments. We do it at least once a month for every claim,” said Shannon.

For big sites, Propeller PPK saves surveyor time

A site like the Hughenden recreational lake might be a larger job than some companies would see regularly, but for Cheshire it highlighted the advantage of the Propeller PPK workflow over traditional drone surveying. The flight area to survey the entire job site is about 90 hectares (222 acres).

“I don’t believe you’d go back to a 10-AeroPoints-on-the-ground workflow after the PPK,” said Shannon.

While Cheshire upgraded to PPK after a regular drone crashed for unknown reasons, they couldn’t be happier that they decided to go with the Propeller PPK solution.

“It’s heaps better. It saves time on top of what we already save without having to put out extra AeroPoints,” noted Shannon.

With Propeller PPK, the Cheshire team can survey their entire site in a couple of hours with just two AeroPoints. This halves the time Cheshire’s surveyor previously had to spend driving the site to lay out ground control.

With traditional drone surveying, it used to take twice as long

With a site like Hughenden, using traditional drone surveying “would have taken the surveyor a whole day after placing all the AeroPoints out to get set up,” explained Shannon. And because the site is unusually large, Cheshire’s in-house surveyor would have had to use about 20 AeroPoints to cover all the ground, as opposed to the conventional 10.

With Propeller PPK removing the need to establish ground control in this manner, drone surveying only takes half a day. Shannon estimates it now takes about 3–4 hours versus 8 hours total, and the surveyor doesn’t have to go where machines are running. “With PPK, the AeroPoints are out of the way,” said Shannon, making it safer for the surveyor while out on site.

“The drone flight itself is reasonably similar [to a regular drone survey],” Shannon said, but PPK frees up his in-house surveyor “to go over quantities and drafting, and other work.”

“I recommend Propeller to others.”

While individual projects vary, Cheshire uses the Propeller Platform from every two weeks to monthly. When the job first began, they were moving a huge amount of dirt, so they surveyed much more frequently to check if their work was on track.

At this stage in the project, things are moving much slower, but they still check Propeller and use the information to do their internal checks and QA all the time.

“Propeller has changed how we do our QA on jobs. Before using drones to survey, we’d had to rely on load counts and delivery dockets for our quantities, but little errors in those measurements can propagate a lot,” explained Shannon. “With the 3D survey, you’ve got a bird’s eye view of the site. You can scale it, and check it, and say, ‘okay, there’s exactly this many square meters and we’ve got exactly this many tons to fill that.’ It gives you the confidence to know that what you’ve put in is right.”

“I’d recommend Propeller to people in my sector. I think it’s the way it’s all going now,” said Shannon. “It’s been efficient. It’s been cost-effective.”

He also notes how much the technology is always changing, improving: “We’ll fly jobs with the drone, and do a design from that, we can then put that design file into the machines. The machines can go and do the job and you don’t even need to put a peg in on the site. You can do everything through the GPS technology, the drone, and Trimble, and everything else. You don’t need to put a peg on site anymore.

“Companies who don’t start looking into this technology, over time, are slowly going to fall behind. Sooner or later everyone’s going to be using it for 90% of work.”