California’s Whitaker Construction Tackles Complex Projects, Stays Cutting-Edge with Propeller

Headquartered in the Central California wine country city of Paso Robles, Whitaker Construction was originally founded in 2007. They’ve been serving California’s central coast since 2009.

Specializing in heavy civil, earthwork, and underground, concrete, and bridge projects, Whitaker has found its niche in unique and creative projects. The variety of Whitaker’s work means not only do they want to be on the cutting edge of technology, they need to be.

“I like to have this company come out on the cutting edge of technology. We were one of the earlier people to adopt GPS,” said Matt Bousman, president and CEO of Whitaker Construction. “We had our first rovers back in ‘07. We got into machine control with the equipment and [drone surveying was] the natural step to add a new level of understanding to the projects.”

So they started using Trimble Stratus, powered by Propeller. Trimble, the global leader in positioning technologies, was an early partner of Propeller. Our teams work closely together to deliver Trimble Stratus survey-grade drone data solutions for the heavy civil industries.

When PPK technology became affordable, the move to drone surveying was a no-brainer

Over the years, Bousman had kept an eye on the evolving technology of drone surveying. “When that PPK drone came out, it really made it an affordable addition to our fleet and what we do,” he said.

With the hardware decided on, Bousman started researching different software solutions like DroneDeploy, Kespry, and Pix4D. “What I found was the Propeller Platform was the most suited to the heavy civil work that we do. The available tools were more suited to what our scope of work is,” he explained.

Whitaker uses the Propeller PPK solution for drone surveying. It’s a fully integrated system for collecting highly accurate drone data using DJI’s Phantom 4 RTK drone and Propeller’s AeroPoints.

“The workflow is simple once you learn it,” said Bousman, but it’s not hard to get up to speed. That goes for the whole company, in fact. “A year ago we were barely considering this because of the cost. Now we’ve implemented a full [drone] program. We have two guys licensed on staff to fly these things.”

Propeller’s 3D models help both clients and Whitaker in decision-making

Construction projects are notoriously complicated. With tight project schedules, everything needs to run like a well-oiled machine. Too often this isn’t the case with work divided among different contractors and surveyors constantly overbooked.

Bousman sees drone surveying and Propeller as an aid in situations like these. “It’s quick information that I can get and can give to the owner. It’s accurate enough for decision-making,” he explained. “It’s a quicker process too. It’s far more cost-effective for me to do it than having an auditor or surveyor out there.”

Using Propeller to protect Whitaker’s scope of work

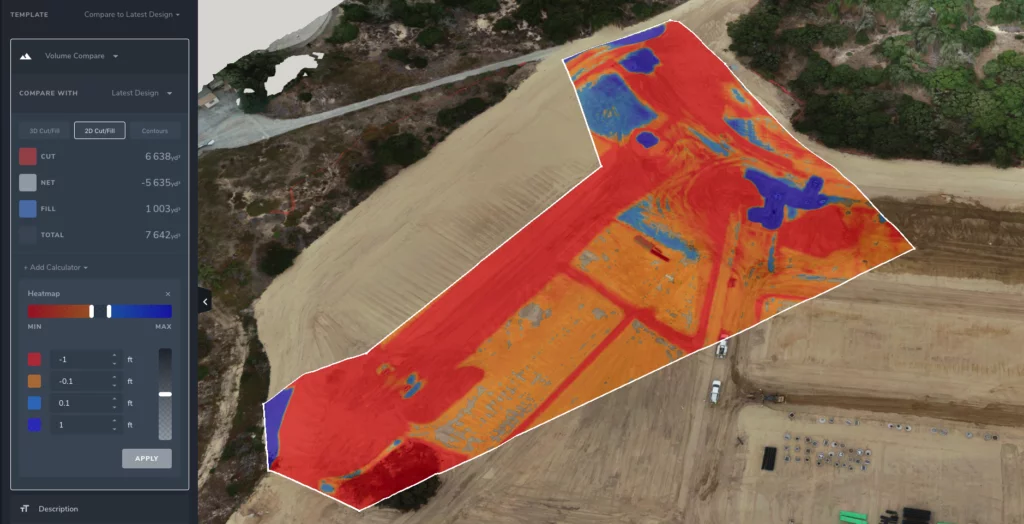

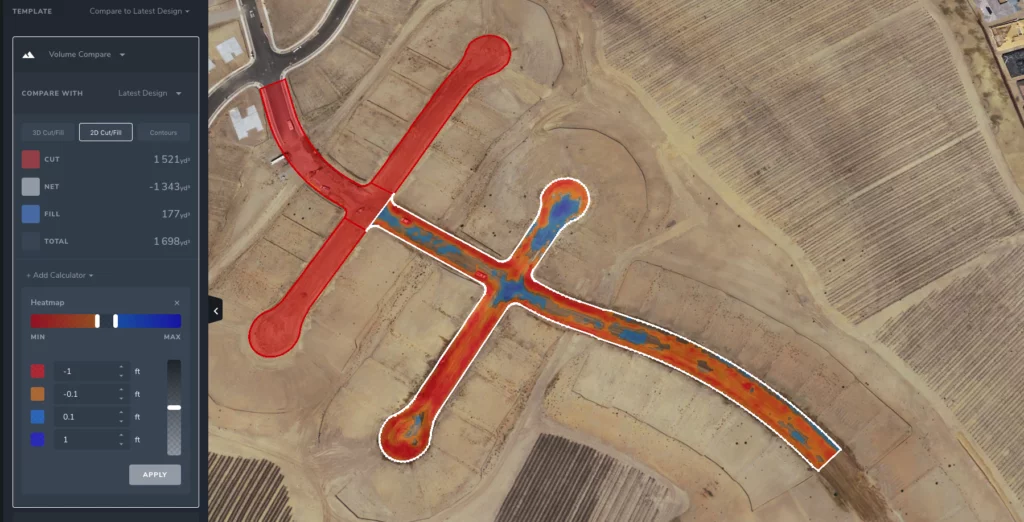

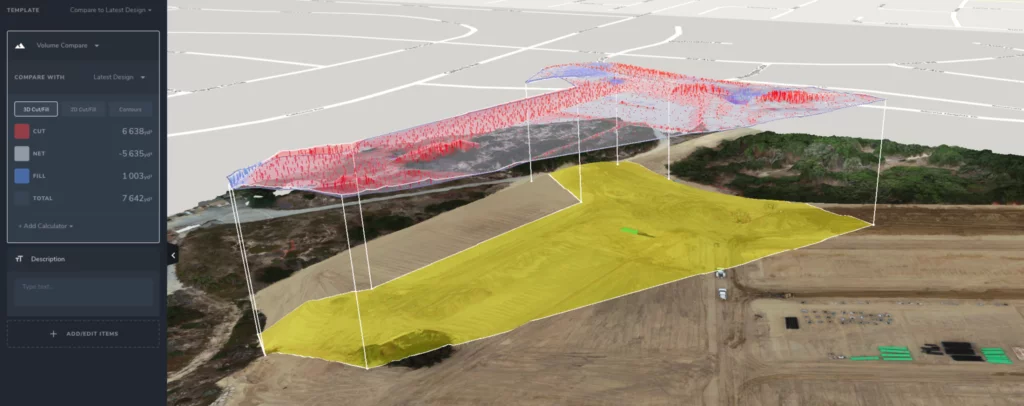

Lately, Whitaker has been working on landfill construction projects. These massive earthwork projects mean moving, tracking, and measuring lots of dirt.

“We’ve been able to figure out where the dirt is, where it needs to go, where it’s coming from, how much cut we have, how much fill we have,” said Bousman.

But as a contractor, Whitaker also needs to be able to communicate effectively with project owners. Propeller helps them with this too. “We’ve gone to owners and shown them ‘here’s what you have.’ If there’s extra work, we’ve been able to support that extra work. It’s also allowed us to plan when we come into a site,” explained Bousman.

Knowing the complete status of a worksite allows Bousman to better plan his team’s schedule. For example, they’ve been hired to do a lot of grading and paving, with other contractors doing the work to setup for that phase of a project.

“We’ll fly in and say, ‘You’re not ready for us yet. Call us when you’re done’,” said Bousman. “It’s allowed us to protect our scope of work and not assume somebody else’s problems or lack of work before we get there. It protects the skillful work that we’re contracted for.”

When Whitaker does start on a project, Bousman said he feels more prepared thanks to Propeller and drone surveying because he can get the answers he needs fast. “With a 3D model, a GPS, and a drone, I can survey something quickly,” he said.

Visual data makes resolving disputes easier on any project

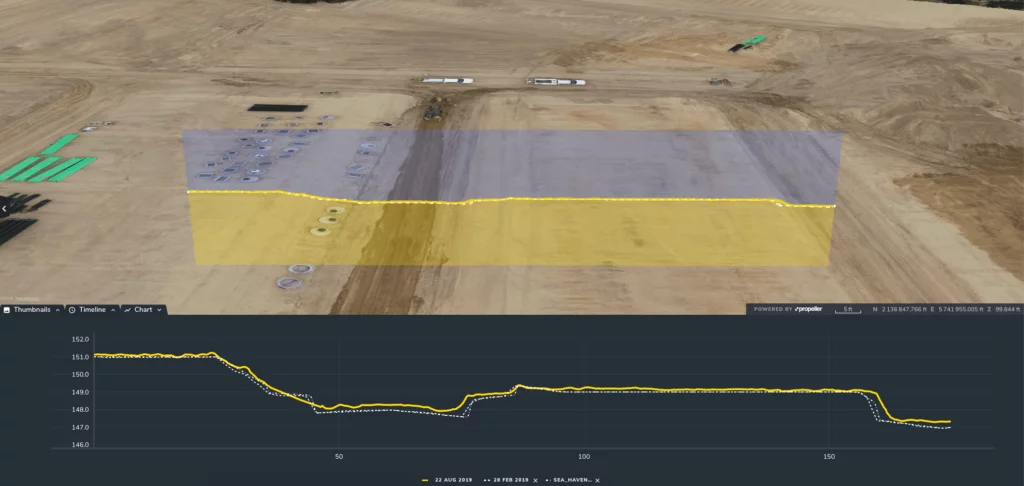

Along with easier data collection in the field, Whitaker gets a lot of value out of highly visual drone survey data.

“[Propeller’s] very visual in its presentation of the data, and I think that’s helpful for everybody,” said Bousman. “Most of the foremen don’t like to look at numbers and charts, but when you can show them a picture of what you’re trying to tell them, it’s very helpful.”

This has come in handy if in-field crews have questions about a particular machine surface. If they call Bousman to raise questions about a grade, he can have them review the plans and see the numbers and visuals for themselves.

Using Propeller can help with more than just confusion on site. It can help with bigger disputes, too. On one of Whitaker’s jobs, they had an abundance of extra material on site, but no one was believing the new numbers.

“So we sat down and looked through it [on Propeller],” recalled Bousman. “It took a little bit because the number was so staggeringly off of what it was supposed to be, but in the end, we [proved] this thing is very accurate.”

With Propeller’s accurate visual data, Whitaker navigates complex project details and disputes

No one wants to use a tool that adds more work to their plate. Surveying their projects by drone empowers Bousman and his team to collect accurate data fast. The Propeller Platform then lets them visualize and analyze it without too much back and forth.

From resolving external disputes to protecting their scope of work, Whitaker gets the answers they need about a job without hassle. They can get back to what really matters: building heavy civil and earthwork projects and getting jobs done on time and on budget.