Choosing Drone Hardware and Software for Your Drone Program

In the last few years, commercial drone surveying has been changing and modernizing traditional workflows on construction, mining, aggregates, and waste management sites all over the world. They provide accurate site data in significantly less time and at lower cost than traditional options.

But when it comes to actually getting a drone surveying program up and running on your site, there can be a lot unknowns about how to do it right. There are two main elements to consider: hardware and software.

Which drone hardware is best for your surveying needs?

Now that you’ve gotten certified and cleared your flight in the airspace surrounding your site, you need to pick the right drone.

Those new to drone surveying tend to put a lot of emphasis on the drone itself when it comes to success and data quality. But you don’t need to spend hours researching, reading product reviews, scouring forums, and evaluating myriad options.

For the most part, a drone is a drone is a drone. It’s a vessel for the camera. After years of working with different sites and seeing every kind of situation under the sun, we recommend the Phantom 4 series for drone surveying. Why? Because it has a high-quality camera; it’s robust and widely available; it’s got a very reasonable price point; and it

works for almost any kind of site. It’s all you need.

There are edge cases related to site size that might require a different set up, but often you still don’t need to turn to expensive, custom-built drones, you could use multiple Phantoms and get the job done right.

It’s hard not to overstate, but the way you use your data makes all the difference. And that’s where data analytics software comes in, which will go into more detail on further down.

Invest in software, it’s what makes your drone surveying data useful

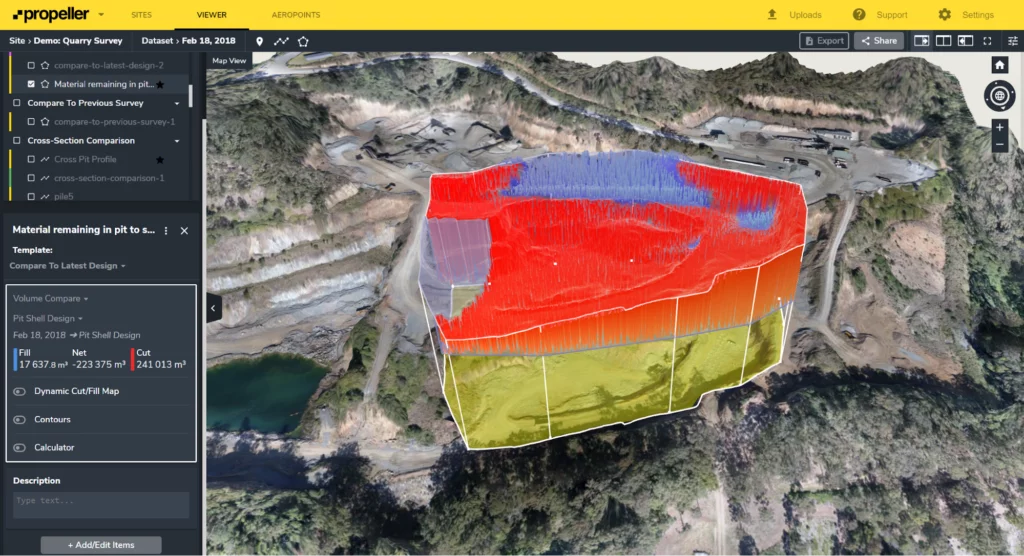

With great mapping and analytics software, you can calculate stockpile volumes in a couple of clicks; check road grades in seconds; monitor environmental zones over time and after big events; track compaction rates and remaining airspace accurately; and so much more.

Investing time and work hours in finding the right software for you needs pays off. Platforms are continually advancing, and while some are optimized for agriculture, others are purpose-built to meet civil contractor and resources industry needs.

A platform like Propeller sits in the latter category. You can track progress and productivity on site, measure quality, and mitigate cost with simple tools anyone can use—all without downloading a single software program. Propeller is cloud-based, and we do all the heavy lifting when it comes to data. No more expensive desktop machines that take days to process data.

Data analytics, planning, quality assurance, and progress tracking—those are the places to focus your time, those are the ways that you can make the biggest difference in efficiency and cost mitigation on your site. So if you’re on a mine, a quarry, a landfill, or a civil construction site, how do you go about picking the right software?

How to pick the best processing software for your site

Figuring out exactly what you need and which vendor is best placed to provide it can be trickier than you think. Choosing the wrong software means risking a “false start”; a setback that can make it harder to win the hearts, minds, and budget needed to make drone data a success for your company.

To help you get it right the first time, let’s break down the savviest questions you can and should ask about your software.

How is the accuracy of the maps and models ensured?

Accuracy is the number-one priority in drone surveying operations, so make sure your vendor understands why ground control is so important. Surveyors overwhelmingly agree that, even when using high-end on-board RTK/PPK GPS, you still need a method of ground control or authentication for the drone data you collect.

Will this solution create another “data silo” in my business?

You likely have established processes you don’t want to disrupt. Ensure software complements existing workflows and makes your day-to-day easier. Your data must be able to be imported, exported, transfigured, and manipulated to suit your unique business needs.

With Propeller, all the data you generate, and every calculation you perform, can be exported and shared, either as a PDF report or a spreadsheet. You can also download your data in a range of custom file formats to use in programs like Trimble Business Center, Carlson, Global Mapper, Maptek I-Sight, Vulcan, Surpac, and more.

Are local site calibrations supported?

If you operate on a local grid, make sure your software supports local site calibrations. Without that capability, you’d need someone in-house with the time and skills required to convert each piece of drone data into local grid coordinates. Processing platforms like Propeller support local coordinate systems, so all your data is delivered in your site’s own “language.”

How is data processing quality ensured? Tell me about the support team.

Today’s processing platforms are expected to provide same-day processing and simultaneous job processing. But you don’t want is speed at the price of quality.

Ask about how “automatic” processing actually works. If there’s a problem with your dataset, how will this be identified and communicated? Who will you be speaking to in this scenario and what are their qualifications? When will they be available to help?

Propeller has an in-house data success team, who are experts in surveying and photogrammetry. With 24/7 support, they personally check each and every job for quality.

How can I be confident in the measurements I make with the software?

A common concern about drone data adoption within the construction, mining, aggregates, and waste management industries is the predictability and repeatability of measurements. Data confidence comes from accuracy validation, both of your survey and individual measurements.

If vendors are slow to provide accuracy metrics, or platform tools don’t easily allow you to validate your own measurements, you should assume that surveys aren’t accurate and measurements won’t be reliable.