How 3D Drone Survey Data is Helping Queensland-based Cheshire Contractors Scale Their Business

Cheshire Contractors Pty. Ltd., a mid-sized construction company, wanted a better look into dirt movement on their sites to better understand who was moving what dirt, where, and when.

Locally owned and operated since 1979, they specialize in civil construction, earthmoving, and heavy machinery. They are based in Queensland, Cape York Peninsula, and the Torres Strait Islands. Cheshire Contractors focuses on projects across the state for clients which include private developers, property developers, local and state government, aquaculture, and the Thoroughbred racing industry.

Recently, Cheshire Contractors was in a $1.2 million contractor dispute simply because they did not have frequent and accurate quantities from site survey data. At the time, they were recording aerial photography of the site, but there was no survey data to prove quantities against a timeline. Cheshire Contractors wanted a solution that would give them transparency into the status of their site and reduce time spent in the field surveying so they could focus on winning larger projects and scaling their business.

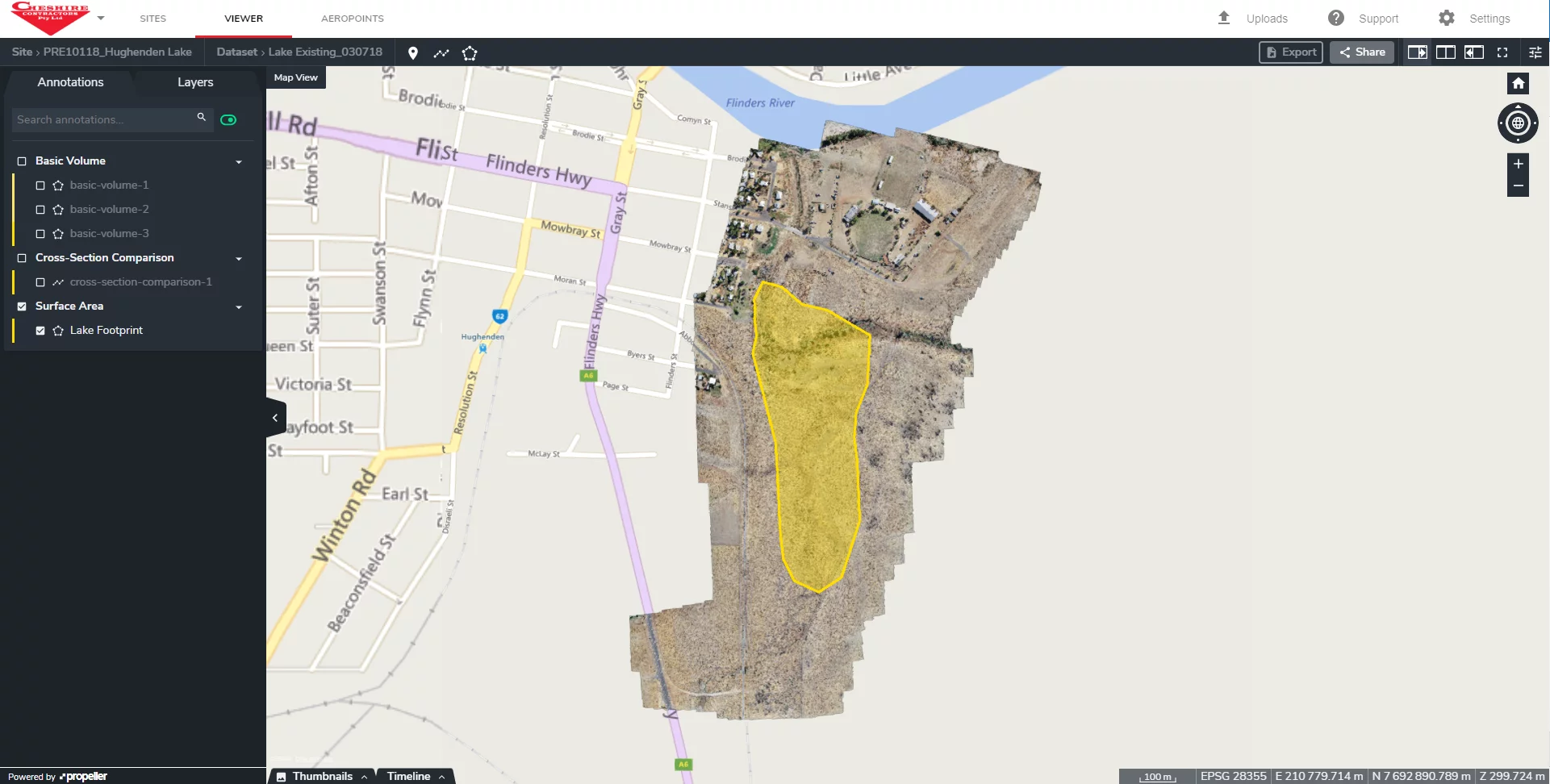

And win larger projects they did. After winning the bid on an 80 hectare (197.6 acre) project, a site that would take close to 20 days to survey, Shannon Cheshire, a contracts administrator and foreman at Cheshire Contractors, knew he had to find a complete solution that combined drone photography with survey-grade data.

Cheshire Contractors chose Propeller because its easy-to-use platform made frequent drone survey capture a reality. It would reduce the time his team spent in the field and produce 3D visualized drone survey data that he could take back to his client—a competitive advantage. “On a large site you have to walk through different terrains, through bush, through standing water, through all kinds of things,” said Shannon Cheshire. “This is a huge project and we have so much dirt to move, we need to track it—often.”

Propeller is helping Cheshire Contractors answer critical questions about the progress of their site. They now have access to real-time, 3D survey data across their portfolio of heavy civil and earthwork projects they can compare against a construction timeline. “That is something you wouldn’t get with normal surveys,” said Shannon Cheshire. “It’s impressive because you can go right in the platform and see everything as it stands today.”

Merely in the preconstruction phase, Cheshire Contractors has already seen a positive ROI. They’ve saved a significant amount of time and money by using Propeller. So far the numbers are adding up to 20 days of ground survey time.

Typically, Shannon Cheshire is charged around $90 per hour per surveyor and $90 per hour for survey equipment. That’s $1,440 over an eight-hour day. He recently won that 80 hectare (197.6 acre) site that could take close to 20 days to survey—a man-hour and equipment cost of $28,880. With Propeller, he surveyed the entire site in just four to five hours and at a cost of $2,400. He put 19 days back on the schedule and was able to get to work on site quicker—a huge feat in itself as it cost nearly $20,000 a day to have his equipment sitting around on site.

This new tool has given Cheshire Contractors a bit of an edge over the competition. “My client has seen aerial surveys before, but they weren’t as accurate and not as detailed,” said Shannon Cheshire, “the footings were measured from hundreds of meters above ground. We fly at 80 meters [262 feet] and everything is so detailed. The quality of the images and the accuracy of Propeller are amazing.”

In the office, the Propeller Platform helps Cheshire Contractors with accurate job costing. “Recently, we were bidding on a prawn farm and we were able to survey with Propeller before we set the pricing so we could get tighter on our numbers.” This means Cheshire Contractors saves both time on bidding and gives better estimates for the contract they’re pursuing.

As they continue to scale up their operations with Propeller, Cheshire Contractors is looking forward to using the tool to understand when they will reach their targets. With up-to-date site data they’ll have an inside look as to whether they are operating profitably. “We’ll know if we’re making or losing money much more quickly, and if there is a problem we can fix it straight away instead of letting it fester,” said Shannon Cheshire. His team plans to fly their sites every two weeks to keep an eye on production. It’s imperative that in-office and on-site teams keep track of where the dirt is going so they can increase operational efficiency by reducing unnecessary earthwork movement.

“Propeller has given us a huge competitive advantage and we’re looking forward to maximizing this tool to its full potential as we grow.”

Download full case study in PDF.